Struggling to pick the right finish for your book-style box? The wrong choice can make a premium product look cheap. Let me guide you through the best options.

Offset printing delivers superior color and detail for book-style rigid boxes. For finishing, I recommend combining matte lamination with spot UV to create a sophisticated contrast. Hot foil stamping is perfect for adding a touch of luxury. These choices ensure a premium look and feel.

Choosing the right printing and finishing is crucial. But before we dive deeper into those specific techniques, it's important to understand the full picture. Rigid boxes are a fantastic choice for many products, but they aren't perfect for every situation. You need to know their limitations to make an informed decision for your clients. So, let’s talk about some of the downsides first.

What are the disadvantages of rigid boxes?

Do you love rigid boxes but worry about their costs and shipping challenges? These concerns can complicate a project. Let’s look at the main disadvantages to prepare for them.

The biggest drawbacks of rigid boxes are their higher unit cost and bulky size. Since they don't ship flat, storage and shipping expenses are much higher. Production also takes longer than for folding cartons. This makes them less ideal for projects with tight budgets or limited space.

It's easy to see why everyone loves rigid boxes. They communicate quality from the moment you see them. But as a designer, you need to present the full picture to your clients. I always walk them through the three main challenges: cost, space, and time.

Cost Implications

Rigid boxes are not cheap. The core material, greyboard, is dense and sturdy. The wrap paper needs high-quality printing. Most importantly, assembly often requires significant manual labor or specialized machinery. I once worked with a startup launching a beautiful skincare line. They were set on a rigid box, but the final quote was a shock. We had to find a creative folding carton solution instead to make the project viable.

Storage and Shipping Woes

Here is a major logistical issue. Rigid boxes do not ship flat. This means they take up a huge amount of space in a warehouse and during transit. For one of our clients, we calculated that one shipping container could hold 50,000 flat-folding cartons. That same container could only hold about 8,000 assembled rigid boxes. This dramatically increases the cost per unit for storage and delivery.

Production Timelines

Creating a rigid box is a multi-step process that takes longer than making a folding carton. You need time for the greyboard to be cut and grooved, for the wrap to be printed and laminated, and for the careful assembly of the final box. This extended lead time needs to be factored into any project plan.

Here’s a simple breakdown:

| Feature | Rigid Box | Folding Carton |

|---|---|---|

| Unit Cost | High | Low |

| Shipping/Storage | Very High (ships assembled) | Very Low (ships flat) |

| Production Time | Long | Short |

| Perceived Value | Very High | Medium to High |

Understanding these points helps you set realistic expectations with clients from the start.

What is a stiff material like very thick paper often used for making boxes?

Ever wonder what makes a rigid box so strong and durable? Using the wrong term or material can cause major production issues. Let's talk about the core material that provides the structure.

The stiff material inside a rigid box is called greyboard or chipboard. It’s a thick, dense board made from recycled paper. This material gives the box its strength, durability, and premium, heavy feel. It forms the core structure that the printed wrap paper is glued onto.

The secret to a rigid box1's strength is its inner frame. This isn't just thick paper; it's a specialized material called greyboard2, or sometimes chipboard. As a designer, understanding greyboard2 is key to creating packaging that is both beautiful and functional. It is the skeleton of your design.

What is Greyboard?

Greyboard is a thick, dense board made from recycled paper pulp. Its name comes from its natural, unfinished grey color. Because its surface is rough and not suitable for direct printing, we always cover it with a printed "wrap" paper. This combination gives you a strong structure with a beautiful, fully-customized exterior3. Its recycled nature also makes it a strong choice for sustainability4.

Choosing the Right Thickness

The most important specification for greyboard2 is its thickness5, usually measured in millimeters (mm). The thickness5 you choose depends entirely on the size, weight, and value of the product inside. A small, lightweight item might only need a 1mm board. A large, heavy, or fragile product might require a 3mm board for proper protection.

I recall a project for a luxury watch. The initial design used a standard 2mm board. It was strong, but it didn't feel 'special' enough. We created a new sample with a 3mm board. The extra weight and sturdiness immediately elevated the unboxing experience6.

Here is a simple guide I use:

| Greyboard Thickness | Common Applications | Feeling & Protection |

|---|---|---|

| 1.0mm - 1.5mm | Small boxes, jewelry, cosmetics | Light, elegant, basic protection |

| 2.0mm - 2.5mm | Electronics, board games, gift sets | Strong, substantial, good protection |

| 3.0mm+ | Heavy items, luxury spirits | Very heavy, premium, maximum protection |

Choosing the right thickness5 is a balance between protection, cost, and the perceived value you want to create.

What are the different types of rigid box1es?

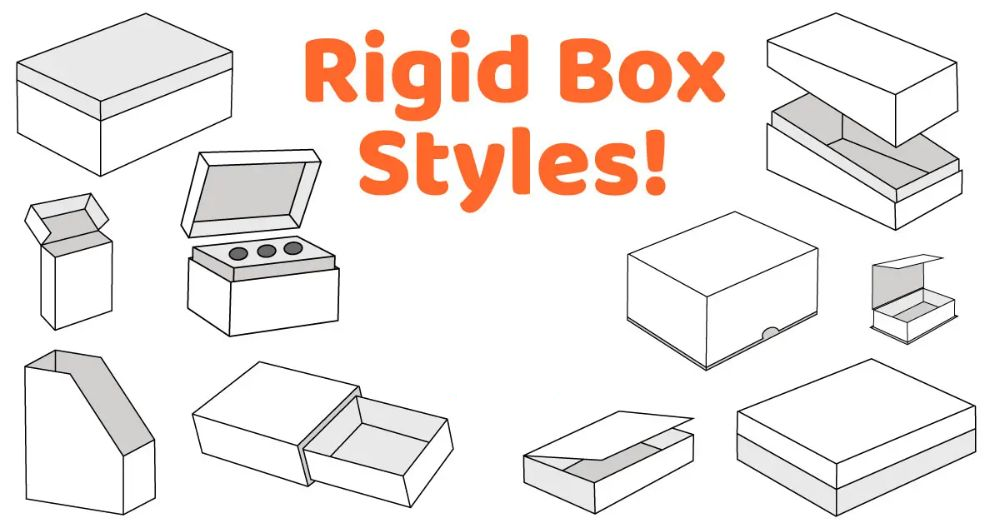

Think a rigid box is just a simple box with a lid? This view can limit your design options. Let me show you the different styles to spark your next great idea.

The most common rigid box types are the two-piece "lid and base" box and the hinged "book-style" box, often with a magnetic closure. You also see "drawer-style" boxes (slipcases) and "collapsible" boxes that can be shipped flat. Each style offers a different unboxing experience6.

A rigid box isn't just one thing. The construction style completely changes how a customer interacts with the product. Choosing the right style is just as important as the graphics you print on it. It directs the entire unboxing ceremony. Over my 16 years in packaging, I've seen these styles used in creative ways.

Lid and Base Box

This is the quintessential rigid box. Think of the classic Apple iPhone box. It has two separate pieces: a base tray that holds the product and a lid that fits over it. You can have a "full telescope" lid that covers the entire base or a "partial telescope" lid that is shorter.

Book-Style Box

This style, the focus of our article, has a hinged lid that opens like a hardcover book. It’s perfect for creating a grand reveal. These often feature magnetic closures for a satisfying click, or a ribbon tie for a touch of elegance. We use this style all the time for high-end corporate gift sets.

Drawer-Style Box

Also called a slipcase, this design features a sleeve and a sliding inner tray. The user pulls the tray out like a drawer. It’s a very sleek and interactive style, ideal for products like jewelry, luxury pens, or high-end chocolates.

Collapsible Rigid Box

This is a brilliant innovation that solves the shipping problem. These boxes are built with clever hinges and pre-applied adhesive, so they can ship flat. The end-user assembles them in seconds. You get the premium rigid feel without the logistical headache.

Here is a quick reference table:

| Box Style | Description | Best For |

|---|---|---|

| Lid and Base | Two-part box with a separate lid and base. | Electronics, board games, luxury apparel |

| Book-Style | Hinged lid that opens like a book, often magnetic. | Gift sets, cosmetics, press kits, books |

| Drawer-Style | A sleeve with a tray that slides out. | Jewelry, small accessories, confectionery |

| Collapsible | A rigid box that can ship flat and be assembled. | E-commerce, products with logistical challenges |

Knowing these options allows you to propose the perfect packaging solution that fits the product and the brand.

What is the difference between a rigid box and a folding box?

Are you unsure when to specify a rigid box1 versus a high-end folding box7? This choice impacts everything from budget to brand perception. Let's clarify the key differences simply.

A rigid box is pre-assembled, extremely durable, and made from thick chipboard, creating a luxury feel. A folding box, or carton, ships flat, is made from a single sheet of paperboard, and is assembled by the user. Rigid boxes are much more expensive and protective.

As a designer, one of the most fundamental choices you will make is between a rigid box and a folding box. They may seem similar, but they serve very different purposes and communicate different messages. I often tell my team that this choice sets the entire tone for the product experience. It’s the difference between a product that feels like a permanent keepsake and one that feels more like a convenient container.

Core Construction and Material

The most obvious difference is the material. A folding carton is made from a single layer of paperboard. We print on it, cut it, and score it. It only becomes a box when it's folded. A rigid box, on the other hand, is a composite structure. It has a thick, non-bending greyboard frame that is then wrapped with a separate, printed paper or fabric layer. This construction gives it superior strength and a characteristic heft.

The Unboxing and User Experience

This is where the differences really shine. Folding cartons are practical. They are easy to open, often with a simple tuck flap or tab. Rigid boxes offer a more ceremonial unboxing. The weight, the sound of a magnetic closure, or the slow slide of a lid from its base all contribute to a feeling of luxury and anticipation. This experience makes rigid boxes perfect for high-value items where you want to make a lasting impression.

Here is the simplest way I can break it down for my clients:

| Aspect | Rigid Box | Folding Box (Carton) |

|---|---|---|

| Structure | Multi-part: Thick greyboard frame + outer wrap. | Single-part: One piece of scored paperboard. |

| Delivery State | Arrives pre-assembled and ready to use. | Arrives flat, requires assembly. |

| Strength | Very high, offers maximum protection. | Good, but less durable and protective. |

| Cost | High. More materials and labor involved. | Low. Efficient to produce and ship. |

| Brand Perception | Premium, luxury, gift, keepsake. | Retail, accessible, functional. |

Ultimately, choosing between them comes down to three things: your client’s budget, your logistical needs, and the story you want the packaging to tell.

Conclusion

Choosing the right printing, finishing, material, and box style is key to creating a successful book-style rigid box that elevates the product and delights the customer.

-

Discover why rigid boxes are preferred for luxury items and how they enhance the unboxing experience. ↩ ↩ ↩

-

Explore the unique properties of greyboard that make it essential for durable and sustainable packaging. ↩ ↩ ↩

-

Explore techniques for designing unique and attractive packaging that stands out. ↩

-

Explore the eco-friendly aspects of greyboard and its role in sustainable packaging solutions. ↩

-

Understanding thickness is crucial for selecting the right material for your packaging needs. ↩ ↩ ↩

-

Discover how thoughtful packaging design enhances customer satisfaction and brand perception. ↩ ↩

-

Understand the key differences to make informed packaging choices for your products. ↩