Having trouble finding the right name for a huge box? The terminology can be confusing. I'll help you understand the correct terms to use for your large-scale shipping needs.

A large cardboard box designed for shipping bulk quantities is most commonly called a bulk box, a pallet box, or a Gaylord box. These terms often describe a heavy-duty, corrugated container sized to fit perfectly on a standard shipping pallet for easy transport and handling.

When you're dealing with logistics, using the right name for your packaging is crucial. It ensures you're on the same page as your suppliers and shipping partners, preventing costly mistakes and delays. Over my 16 years in this industry, I've seen how simple miscommunications about box types can lead to major headaches. Let's dive deeper into the specific names and what they mean so you can order exactly what you need with confidence every time.

What are the big cardboard boxes called?

You need to ship a large volume of products, but what do you call the box? Using the wrong term can lead to confusion. I can clear up the common industry names.

Big cardboard boxes are generally called bulk boxes, pallet boxes, or octabins. The name often depends on its specific design and purpose, but all are made to hold large quantities of goods and are typically sized to fit on a pallet for efficient shipping.

When you need to ship a large quantity of items, especially loose ones, you can't just use a standard shipping box. You need something much bigger and stronger. These large containers are essential for industries from agriculture to manufacturing. In my experience, understanding the differences between them is key to optimizing your supply chain. For a product designer like Peter, choosing the right one can impact everything from product safety to shipping costs.

Let's break down the most common types:

Pallet Boxes

These are the most common. As the name suggests, their dimensions are designed to match a standard pallet size perfectly, like 48x40 inches. This maximizes space on a truck or in a shipping container, which is a huge factor in cost savings. They usually have a top and bottom tray design, making them easy to load and unload.

Bulk Boxes

This is a more general term. It can refer to any large corrugated container used for shipping goods in bulk. While many bulk boxes are also pallet boxes, the term can also describe custom large boxes that might not fit standard pallet dimensions perfectly.

Octabins

An octabin is a special type of bulk box with eight sides. I remember a client who shipped small, heavy plastic components. Their square boxes were bulging under the weight. We switched them to octabins. The eight-sided shape provides much better structural integrity and resists bulging, protecting the contents more effectively.

Here's a simple comparison:

| Box Type | Key Feature | Common Use |

|---|---|---|

| Pallet Box | Sized to fit a standard pallet | General bulk shipping, logistics |

| Bulk Box | A general term for any large box | Loose items, irregular-shaped products |

| Octabin | Eight-sided for superior strength | Granular products, small heavy parts |

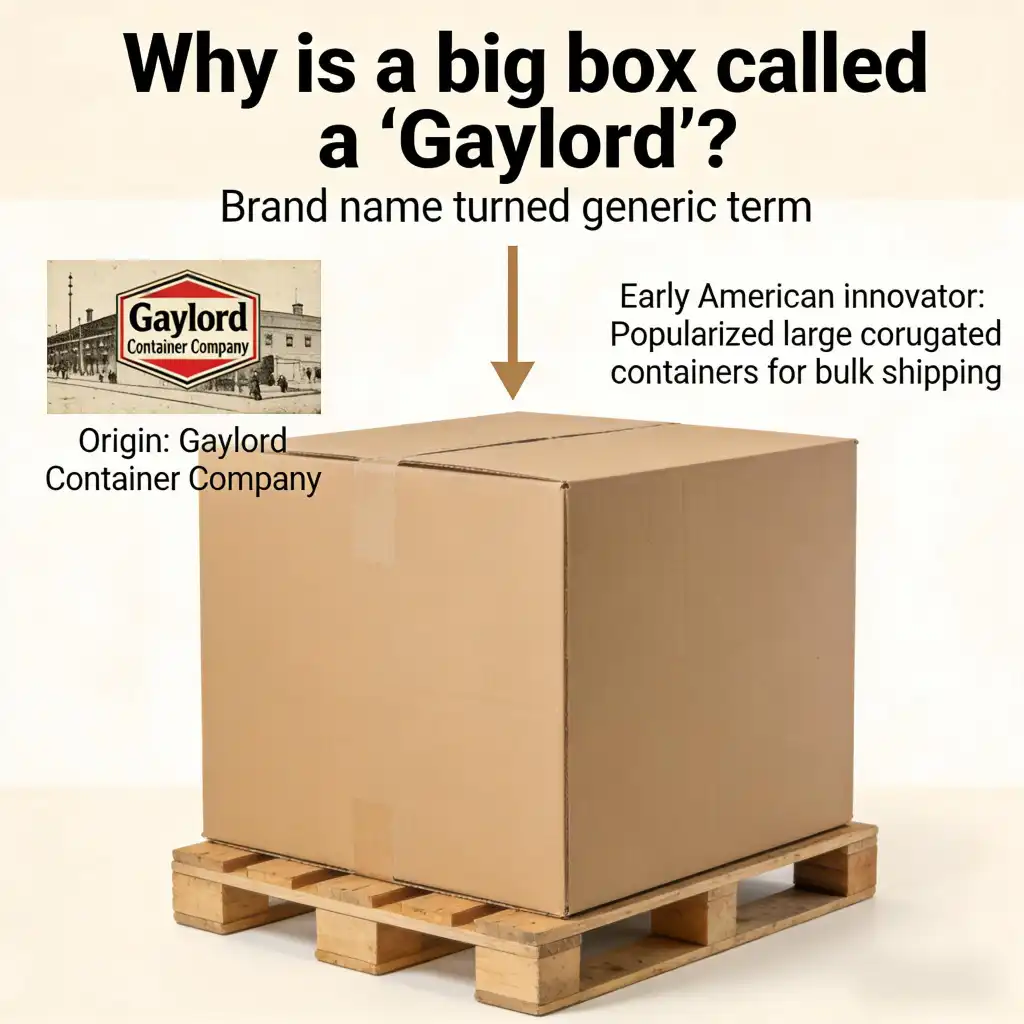

Why is a big box called a Gaylord?

Have you ever heard someone call a large pallet box a "Gaylord"? It's a common term in the industry, but it sounds a bit odd. I'll explain its simple origin.

A big box is often called a "Gaylord" because it's a brand name that has become a generic term. It comes from the Gaylord Container Company, an early American innovator that popularized this style of large, pallet-sized corrugated container for bulk shipping.

The name "Gaylord" is a classic example of how a brand name can become synonymous with a product type. It's just like how people say "Kleenex" for a tissue or "Band-Aid" for an adhesive bandage. The Gaylord Container Company was one of the first and most successful companies to produce these massive boxes, so their name stuck. For many old-timers in the logistics world, any pallet-sized box is simply a "Gaylord."

The Power of a Brand Name

When a company pioneers a product and dominates the market, its name can become the default term. This happened with Gaylord boxes in the United States. They set the standard for bulk bins, and their brand became a shortcut for describing them. While the original company has been acquired and absorbed over the years, the name lives on in warehouses and shipping docks across the country.

Should You Always Call It a Gaylord?

As a designer, it’s important to be precise. While many people in the industry will know what you mean by "Gaylord," it's not a technical specification. Early in my career, a customer asked for a Gaylord box. I sourced a perfect pallet-sized box from another supplier. The customer was confused because it didn't have the Gaylord brand on it. It was a good lesson for me. To avoid any confusion, it is always better to specify the exact dimensions, wall thickness (e.g., double-wall, triple-wall), and strength requirements (like ECT or Mullen rating) rather than just using a brand name. This ensures you get the exact performance you need, no matter who manufactures the box.

What are those giant containers called?

Thinking even bigger than a cardboard box on a pallet? You need to move goods across oceans. What are those giant metal boxes you see on ships and trains called?

Those giant steel containers used for global transport are called intermodal containers, shipping containers, or freight containers. They are standardized to be moved between different modes of transport—ships, trains, and trucks—without having to unload and reload the contents.

It's crucial to distinguish between a large cardboard box and a shipping container. They work together but serve very different purposes. A Gaylord or pallet box is considered secondary packaging; it holds your products. An intermodal container is tertiary packaging; it holds dozens or hundreds of your pallet boxes for the long journey. As a packaging designer, your goal is to create packaging that fits perfectly and safely inside these giant steel boxes.

Cardboard Bulk Bins vs. Steel Containers

The bulk boxes we've discussed are made of corrugated fiberboard. They are designed for a single pallet's worth of goods and offer protection for domestic shipping or for organizing goods inside a larger container. Intermodal containers, on the other hand, are built from heavy-duty steel to withstand the harsh conditions of ocean travel, stacking, and repeated handling.

Common Types of Intermodal Containers

Not all shipping containers are the same. They come in various types designed for different kinds of cargo. Understanding this can help you design packaging that is compatible with the container it will travel in.

| Container Type | Description |

|---|---|

| Standard Dry Van | The most common type, fully enclosed and weatherproof. |

| Refrigerated (Reefer) | Insulated and equipped with a refrigeration unit for perishable goods. |

| Open Top | Has a removable roof, used for oversized cargo that must be loaded from above. |

| Flat Rack | Has collapsible sides, used for heavy machinery or vehicles. |

Your job as a designer is to maximize the space inside a standard dry van container. Every cubic inch you save by designing efficient pallet boxes translates directly into lower shipping costs for your client.

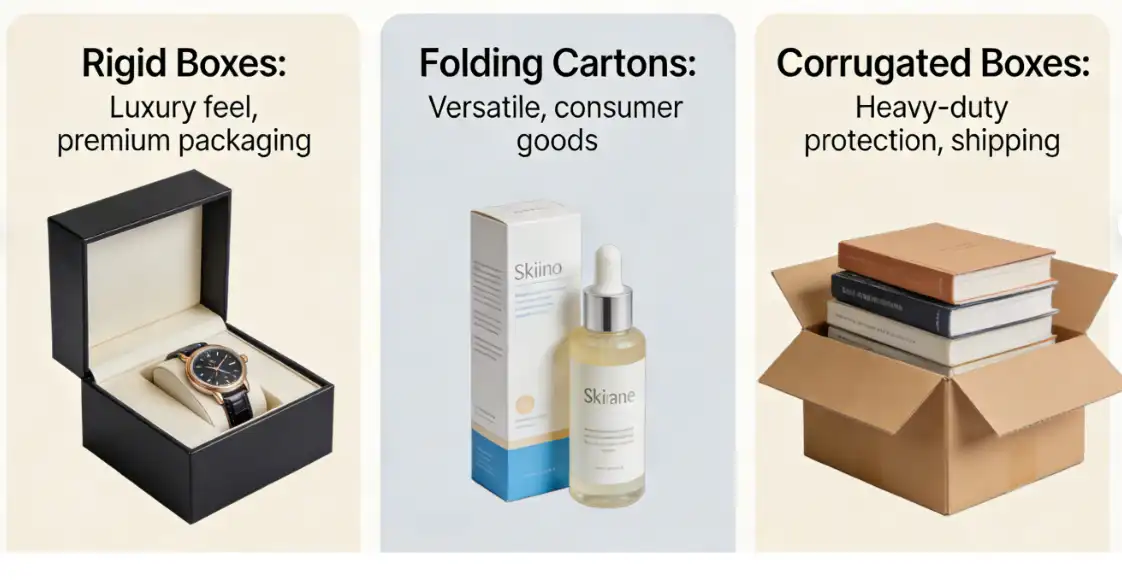

What are the three types of boxes?

The world of boxes seems simple, but it's not. There are key categories that every product designer must know. I will break down the three main types for you.

The three fundamental types of boxes are folding cartons, rigid boxes, and corrugated boxes. Each is defined by its material and construction, making it suitable for different purposes, from retail shelves to heavy-duty shipping.

Understanding these three core categories is the foundation of good packaging design. Each one offers different levels of protection, presentation, and cost. When I consult with clients, one of the first things we determine is which type of box is right for their product and supply chain. Getting this choice right from the start saves a lot of time and money. The big pallet boxes we've been talking about fall into one of these categories, but it's important to see the whole picture.

Folding Cartons

These are the boxes you see every day on supermarket shelves. Think of a cereal box or a toothpaste box. They are made from paperboard, which is essentially a thick paper stock. They are printed and then die-cut and scored so they can be shipped flat to the factory. This saves a lot of money on shipping and storage. They are great for retail but offer minimal protection.

Rigid Boxes

Think of the box your smartphone came in. That's a rigid box. They are made from a thick, condensed paperboard (chipboard) that is then wrapped with a decorative paper or fabric. They are much more durable and have a premium feel. Unlike folding cartons, they don't collapse, so they take up more space during shipping. They are used for luxury goods where presentation is key.

Corrugated Boxes

This is the category where our big Gaylord boxes belong. Corrugated boxes are what people commonly call "cardboard." They are made of a fluted sheet of paper sandwiched between one or two flat linerboards. This structure creates a lightweight but very strong material, perfect for shipping. The strength can be adjusted by changing the thickness of the liners and the size of the flutes.

Here's how they compare:

| Box Type | Material | Key Feature | Common Example |

|---|---|---|---|

| Folding Carton | Paperboard | Ships flat, excellent for printing | Cereal box |

| Rigid Box | Wrapped chipboard | Does not collapse, premium feel | iPhone box |

| Corrugated Box | Fluted paper between liners | High strength-to-weight ratio | Shipping box |

Conclusion

Knowing the right terms, like pallet box or Gaylord, ensures you can communicate clearly with suppliers. This helps you get the exact high-strength packaging your bulk shipping projects need.