Struggling with flimsy packaging that damages your product? A crushed box on the shelf means lost sales and a poor brand image. The right material is your first line of defense.

Cereal boxes are typically made from paperboard, a thick paper-based material. The most common types are Clay Coated News Back (CCNB) and Solid Bleached Sulfate (SBS). These are chosen for their ideal mix of strength, smooth printing surface, and cost-effectiveness for high-volume production.

In my 16 years in the packaging industry, I've handled thousands of projects. The question of material is always the starting point. It’s not just about holding cereal; it’s about protecting the product, showcasing the brand, and doing it all efficiently. Many people think a box is just a box, but the science behind choosing the right paperboard is what separates a successful product from a failure. It's a balance of art and engineering. Let’s explore why these materials are the industry standard and how you can leverage them for your own designs.

Why Is Paperboard the Go-To Material for Cereal Boxes?

Choosing the wrong material can increase your costs and harm your brand's reputation. A box that looks cheap or fails to protect the cereal inside disappoints customers before they even open it.

Paperboard is the top choice because it offers the perfect trifecta: structural integrity to protect the cereal, a superior surface for vibrant and attractive printing, and it is lightweight and cost-effective for shipping and mass production. It's the most balanced solution.

When I work with designers like Peter, we always come back to the core functions of the package. For cereal, the priorities are clear. The box must survive the journey from the factory, to the warehouse, to the grocery store shelf, and finally to the customer's pantry. Paperboard provides this necessary rigidity without being as heavy or expensive as corrugated cardboard, which would be overkill.

Then there's the marketing aspect. The cereal aisle is one of the most competitive spaces in a store. Your box needs to shout from the shelf. Paperboard's smooth, often coated surface is a perfect canvas. It allows for:

- Sharp Graphics: High-resolution images and bright colors pop, grabbing a child's or parent's attention.

- Clear Text: Nutritional information and branding are crisp and easy to read.

- Custom Finishes: Techniques like embossing or foil stamping are easily applied.

From a production standpoint, it’s a dream material. It’s easily scored, folded, and glued by automated machinery, keeping production speeds high and costs low. This efficiency is why major brands rely on it. It’s the engine that powers the entire cereal packaging world.

How Do Different Paperboard Types Affect Your Cereal Box Design?

You know paperboard is the answer, but which kind? Choosing incorrectly can lead to printing issues or a box that feels cheap, undermining your design efforts and the premium feel you're aiming for.

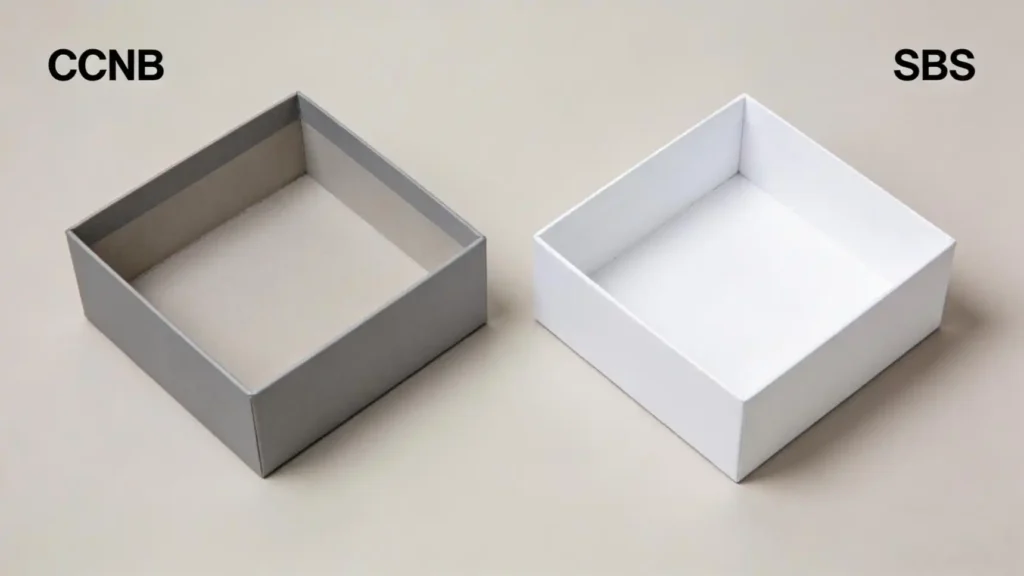

The two main types, CCNB and SBS, offer different benefits. Clay Coated News Back (CCNB) is cost-effective and eco-friendly, made from recycled materials. Solid Bleached Sulfate (SBS) is a premium, virgin-fiber board offering superior brightness, stiffness, and purity for high-end products.

As a packaging specialist, this is where the conversation gets interesting. The choice between CCNB and SBS directly impacts the final product's look, feel, and cost. It's a strategic decision a designer must make with the client. I've guided countless clients through this choice, and it often comes down to balancing brand perception with budget.

Here's a simple breakdown I use to help designers decide:

| Feature | Clay Coated News Back (CCNB) | Solid Bleached Sulfate (SBS) |

|---|---|---|

| Composition | Recycled paper layers with a top clay coating. | Solid virgin bleached wood pulp. |

| Appearance | White, smooth top; grayish or brownish back. | White and smooth on both sides. |

| Best For | Cost-sensitive projects, eco-conscious brands. | Premium products, food-safe applications. |

| Printability | Very good on the coated side. | Excellent, superior brightness and color fidelity. |

| Stiffness | Good, but less rigid than SBS of the same weight. | Higher stiffness and a more rigid feel. |

For most standard cereals, CCNB is the workhorse. It prints beautifully on the outside, and the grayish interior isn't a concern since the cereal is held in a separate plastic bag. However, for an organic, luxury, or health-focused brand that wants to convey purity from the inside out, the clean, white interior of an SBS paper box might be worth the extra investment. It’s a subtle detail that communicates quality.

What Are the Finishing Touches That Make a Cereal Box Stand Out?

Your box is made from the right material, but it looks just like every other box on the shelf. Without unique features, your design gets lost in the crowd, failing to capture consumer attention.

Finishing techniques like gloss or matte varnishes, embossing, and foil stamping elevate a standard box. These tactile and visual enhancements create a premium feel, make graphics pop, and help your product stand out in a competitive environment.

This is where the magic happens. The structure is the skeleton, but the finishes are the personality. In my experience, a small investment in a finishing process can yield a huge return in shelf appeal. When I consult with product designers, I always encourage them to think beyond just the printed graphics. We discuss how the box will feel in the customer's hands.

Here are some of the most effective options we implement:

- Varnish & Lamination: A gloss varnish makes colors look richer and adds a shiny, protective layer. A matte or soft-touch lamination offers a modern, sophisticated, and tactile feel.

- Embossing/Debossing: This technique raises (emboss) or recesses (deboss) parts of the design, like a logo or mascot. It adds a 3D texture that invites touch and communicates high quality.

- Foil Stamping: Applying metallic foil (gold, silver, or colors) creates a sense of luxury and celebration. It's perfect for special editions or premium lines.

- Window Patching: A die-cut window with a clear film patch allows customers to see the actual cereal inside. This builds trust and can be very effective for cereals with unique shapes or colors.

Combining these finishes on your custom cereal boxes creates a multi-sensory experience. A customer is more likely to pick up a box that has an interesting texture or a flash of metallic foil, and once it's in their hands, they are one step closer to buying it.

How Can You Make Your Cereal Packaging More Sustainable?

Consumers are more eco-conscious than ever. Using materials that are not recyclable or come from unsustainable sources can lead to negative brand perception and alienate a growing market segment.

To make cereal packaging more sustainable, use paperboard with a high percentage of post-consumer recycled content (like CCNB). Also, opt for soy-based inks over petroleum-based ones and ensure any plastic liners are recyclable. Communicating these eco-friendly choices on the packaging itself is key.

Sustainability is no longer a niche concern; it's a core business requirement. Over the past decade, I've seen a massive shift in client priorities. Everyone wants to know how to make their packaging greener. For cereal boxes, the path is quite clear. Paperboard is already a fantastic starting point because it's recyclable and biodegradable.

But we can do better. Here are the steps I recommend to clients who are serious about sustainability:

- Maximize Recycled Content: Specify a paperboard with the highest possible percentage of post-consumer recycled content that still meets your structural and printing needs. CCNB is a natural fit here.

- Choose Eco-Friendly Inks: Soy-based or vegetable-based inks are less harmful to the environment than traditional petroleum-based inks and make the paperboard easier to de-ink during the recycling process.

- Rethink the Inner Bag: The plastic bag inside is the least eco-friendly part. Explore options for bags made from recycled plastics or plant-based, compostable materials. This is an area of huge innovation right now.

- Design for Recyclability: Avoid mixing materials that can't be easily separated. If you use a plastic window, ensure it can be easily removed or is made from a compatible recyclable polymer. Our team at Giftspack can help navigate these technical requirements.

By making these choices, you not only reduce your environmental footprint but also gain a powerful marketing story. Printing a simple icon or message like "This Box is 100% Recyclable" can strongly influence a purchase decision.

Conclusion

From structural integrity to vibrant finishes and sustainability, the material of your cereal box is crucial. Choosing the right paperboard and enhancements will protect your product and captivate customers.