Struggling to understand the complex box-making process? It feels overwhelming with so many steps and choices. I'll break down the entire manufacturing journey for you from start to finish.

Manufacturing packaging boxes involves designing, prototyping, choosing materials, printing, surface finishing, die-cutting, and assembling. Each step is crucial for creating a box that protects your product, represents your brand, and meets your budget. It’s a precise, multi-stage process from concept to the final product.

I've spent over 16 years in the packaging industry, and I believe that understanding the process is key to creating great packaging. The journey from a simple idea to a finished box is fascinating, but it can seem complex from the outside. Let's explore each part of this process together. This will help you understand exactly how your vision comes to life and how you can make better decisions for your brand.

How are packaging boxes actually made?

Curious about the factory floor magic? The transformation from a flat sheet to a 3D box seems complicated. I'll walk you through the core production steps right now.

Boxes are made by first printing designs onto large sheets of paperboard. These sheets then go through finishing processes like lamination. After that, a die-cutter cuts and scores the box shape. Finally, the cutouts are folded and glued to form the finished packaging box.

The factory process is a beautifully organized flow. It’s all about turning a flat piece of paper into a functional, three-dimensional structure. My team at Giftspack has perfected this process over many years.

From Digital to Physical: Pre-Press and Printing

Everything starts with your design file. Our pre-press team checks it carefully. They ensure the colors are correct and the layout matches the physical box structure, which we call a dieline. Once approved, we move to printing. We use large offset printing machines that transfer your design onto huge sheets of paperboard. For a designer like you, Peter, this is where your vision starts becoming a reality. We pay close attention to color matching, whether it’s CMYK or a specific Pantone color, to ensure your brand identity is perfectly represented.

Shaping and Finishing: The Transformation

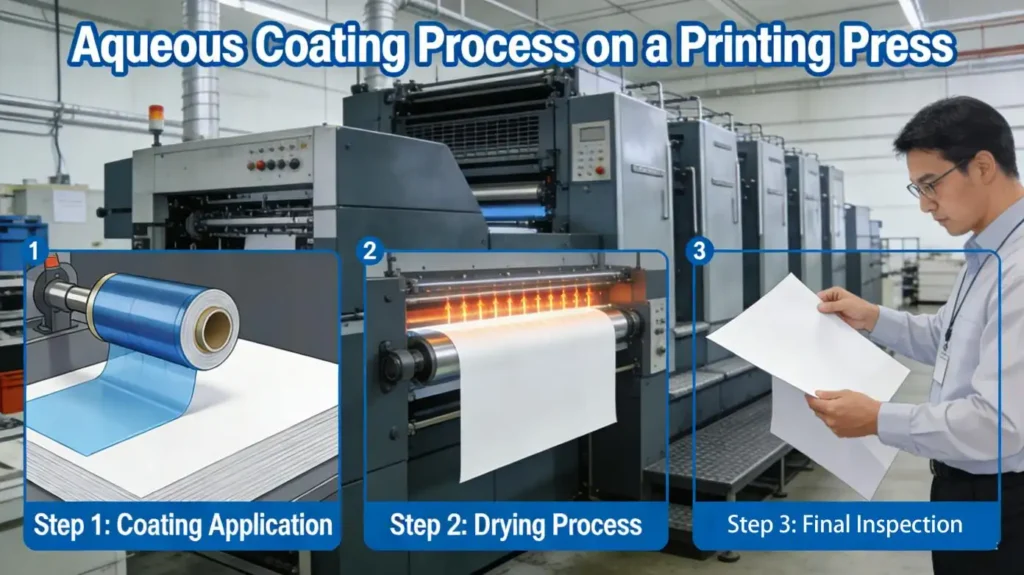

After printing, the sheets might get a special finish. This could be a gloss or matte lamination for protection, or maybe some foil stamping for a premium look. The next critical step is die-cutting. A custom-made tool, or "die," with sharp blades and creasing rules is pressed onto the sheet. It cuts the box outline and scores the fold lines with extreme precision. Finally, the flat, cut-out pieces go to the gluing machines. These machines automatically fold and glue the boxes into their final shape, ready for shipping.

| Stage | Description | My Key Consideration |

|---|---|---|

| 1. Printing | Designs are transferred to the paperboard using offset or digital methods. | Color accuracy is everything for branding. |

| 2. Finishing | Lamination, varnishing, or foiling is applied to protect and enhance the design. | This must balance aesthetics with the budget. |

| 3. Die-cutting | A custom die cuts the box shape and creates fold lines (scores). | Precision here is critical for easy assembly later. |

| 4. Gluing & Assembly | The flat, cut-out "blanks" are folded and glued into their final 3D form. | We check glue strength and placement constantly. |

How can you make your own packaging box?

Want to create a unique box for a small project or prototype? Sourcing from a factory seems too big for your needs. Here’s how you can make one yourself.

To make your own box, first find or create a design template, also known as a dieline. Print this template onto sturdy cardstock. Then, carefully cut along the solid lines and score along the dashed lines. Finally, fold the box into shape and secure it.

Making a box by hand is a great way to test an idea. It’s how I started experimenting with new structures in my early days. It gives you a real feel for the material and how your design works in 3D. While it’s not scalable for business, it is an essential skill for any designer.

The DIY Toolkit: What You'll Need

You don't need a lot of fancy equipment to get started. Most of what you need can be found at a local craft store or even around your house. Having the right tools makes the job much easier and gives you a cleaner, more professional-looking result. A sharp knife, for example, is much better than scissors for straight, clean cuts.

Step-by-Step DIY Box Creation

First, finalize your dieline on a computer and print it directly onto your cardstock. Make sure your printer can handle the thickness of the paper. Next, place the cardstock on a cutting mat. Use a steel ruler and a craft knife to cut along all the solid outer lines. Then, use a scoring tool or the back of a butter knife to press down along the fold lines. This creates a crease that allows for a sharp, clean fold. After cutting and scoring, carefully fold the box into its shape. Apply a thin layer of craft glue or use double-sided tape on the tabs to assemble and secure your box.

| Tool | Purpose | My Pro-Tip |

|---|---|---|

| Cardstock/Paperboard | The main material for your box. | For a sturdy box, I recommend using paper that is at least 250 GSM. |

| Printer | To print your design and dieline. | Check your printer's specs to avoid paper jams with thick stock. |

| Craft Knife & Ruler | For cutting the box shape. | A sharp blade is safer and gives a much cleaner edge. Always use a metal ruler. |

| Scoring Tool | To create clean fold lines. | This is the secret to professional-looking folds. Don't skip this step. |

| Glue/Double-sided Tape | For assembling the box. | Glue gives a stronger bond, but tape is quicker and less messy for prototypes. |

How do you start a carton box manufacturing business?

Thinking of turning your packaging passion into a business? The initial investment and knowledge required can feel daunting. Let’s outline the foundational steps to get started.

Starting a carton box manufacturing business requires a solid business plan, significant capital for machinery, and a deep market understanding. You need to secure a facility, purchase printing, die-cutting, and gluing machines, and build a skilled team to manage production and sales.

When I started Giftspack 16 years ago, I began from the ground up. It was a journey of learning, hard work, and building relationships. Starting a manufacturing business is a huge commitment, but it's incredibly rewarding to see your own factory produce packaging that helps other brands succeed.

The Business Blueprint: Planning and Capital

Your business plan is your roadmap. It must include a thorough analysis of the market. Who are your target customers? What is your competition? Most importantly, you need detailed financial projections. Machinery is expensive, and you need to account for costs like rent, raw materials, and salaries. My advice is to start with a specific niche. Maybe you focus on luxury cosmetic boxes or eco-friendly packaging. It’s easier to become an expert in one area first. Be conservative with your financial estimates. Unexpected costs always come up.

The Operational Core: Machinery and People

Your factory's heart is its machinery and its people. You will need a printing press, a die-cutter, and a folder-gluer at a minimum. You can buy new or used equipment. I started with some reliable used machines to save on initial capital. Just be sure to check their maintenance history. Even more important than the machines are the people who run them. Your first hires are critical. You need skilled operators, creative designers, and a sales team that understands your customers' needs. These early team members will set the culture of your entire company. Also, build strong relationships with your paper and ink suppliers. They are not just vendors; they are your partners in success.

| Key Area | Core Components | My Advice from Experience |

|---|---|---|

| Business Plan | Market analysis, financial projections, target audience. | Don't underestimate initial costs. Start with a specific niche to stand out. |

| Machinery | Printing press, die-cutter, folder-gluer machine. | Used equipment can save capital, but always check maintenance records first. |

| Team | Skilled operators, designers, sales team, quality control. | Your first hires are the most important. They build your company's culture. |

| Supply Chain | Reliable paper suppliers, ink providers. | Build strong supplier relationships. They are essential partners for your growth. |

How exactly are boxes made in a factory?

Ever wondered what a large-scale production run really looks like? The process seems hidden behind factory doors. I'll give you a behind-the-scenes look at the high-volume flow.

In a factory, box making is an assembly line process optimized for speed and consistency. It starts with pre-press checks, followed by high-speed printing. Automated machines then handle finishing, die-cutting, waste removal, and high-speed folding and gluing for thousands of units.

The difference between making one box by hand and making 10,000 in a factory is all about process, automation, and scale. In my factory, every step is optimized to produce high-quality boxes efficiently while minimizing waste. It’s a system we've refined over many years.

The Role of Design and Prototyping

Before we produce thousands of boxes, we focus on just one. The design and prototyping phase is critical. A designer like Peter sends us a structural design file. My engineering team and I review it to ensure it’s not just beautiful but also manufacturable. We check if the folds are logical and if the structure is strong enough for the product. We often create a few physical prototypes for the client to approve. This step prevents costly mistakes down the line. A design that is difficult to glue or assemble can cause huge delays and increase costs during mass production. We work with our clients to balance their creative vision with manufacturing realities.

The High-Volume Production Flow

Once the prototype is approved, we move to production. The process is similar to the basic steps but on a massive scale. Printing happens on presses that can print thousands of large sheets per hour. Finishing, like lamination, is done by large automated machines. The die-cutting press stamps out box shapes with immense force and precision. An interesting step here is "stripping," where machines automatically remove the waste paper from around the cut boxes. Finally, the flat blanks are fed into a folder-gluer. This incredible machine can fold and glue thousands of boxes per hour, all with perfect consistency.

| Aspect | Factory Production | DIY / Small Scale |

|---|---|---|

| Speed | Thousands of boxes per hour. | A few boxes per hour. |

| Consistency | Extremely high due to automation. | Varies with skill and patience. |

| Cost per Unit | Very low for large quantities. | High due to manual labor and material costs. |

| Customization | Extensive (materials, finishes, structures). | Limited by available tools and materials. |

| Setup | Requires expensive custom dies and plate setup. | Simple, requires only a digital template. |

Conclusion

Manufacturing packaging boxes blends art with science. It’s about balancing design, protection, and cost to create something special for your brand. Understanding this process empowers better design choices.