Are you worried about your packaging sample? A bad prototype can derail your entire production run, costing you time and money. Here’s how to get it right the first time.

The custom packaging sample process involves approving a design, creating a prototype (first for structure, then with printing), and conducting rigorous checks. You must verify dimensions, materials, print quality, and ease of assembly. This ensures the final product perfectly matches your vision before you commit to mass production.

Getting a sample in your hands is an exciting moment. After all the design work, you finally see your vision come to life. But this is also the most critical checkpoint in the entire process. Approving a flawed sample means you're approving a flawed production run. Over my 16 years in this industry, I’ve seen this happen, and it’s always painful. That's why I want to walk you through the entire journey, from the initial concept to the final checks, so you can feel confident every step of the way. Let's make sure your packaging isn't just beautiful, but also perfectly functional.

What is customized packaging1?

Does a generic, off-the-shelf box fail to represent your unique brand? Using standard packaging can make a high-quality product look cheap and forgettable. Custom packaging solves this problem.

Customized packaging is packaging designed and produced specifically for your product and brand. It goes beyond standard sizes, incorporating unique dimensions2, materials3, graphics, and unboxing experiences4. This approach helps your product stand out, protects it better, and strengthens your brand identity with customers.

When people hear "custom packaging," they often just think of a logo printed on a box. But it’s so much more than that. It's about creating a tailor-made home for your product. Over my years at Giftspack, I’ve worked with countless clients who transformed their brand perception with customization. I remember one client selling handmade soaps. They were using plain brown boxes, and sales were flat. We designed a simple, elegant paper box with a custom insert to hold the soap snugly. We used a textured, eco-friendly paper stock and a clean, minimalist print. It wasn't expensive, but it made the product feel special. Their sales doubled in three months. That’s the power of creating an experience that begins the moment your customer receives the package.

| Feature | Generic Packaging | Customized Packaging |

|---|---|---|

| Fit | May be too large or too small | Perfectly sized for the product |

| Branding | None or very limited | Fully branded with logos, colors, and messages |

| Protection | Basic, one-size-fits-all | Optimized for the product's specific needs |

| Customer Experience | Forgettable | Creates a memorable unboxing moment |

| Material | Standard, often cheap | Selected for branding, protection, and sustainability |

What considerations should be made for your packaging design?

Feeling overwhelmed by all the decisions in packaging design? Missing just one small detail can lead to big, expensive problems later on. I'll give you a clear list of what to focus on.

When designing packaging, consider your product's practical needs like size, weight, and fragility. Also, focus on your brand identity, including logos and colors. Don't forget your budget, the unboxing experience you want to create, and sustainability goals5. Finally, think about how it will be shipped.

Before you can even request a sample, you need a solid design. Your design is the blueprint for everything that follows. I always tell my clients to think about it from three perspectives: the product, the brand, and the customer.

Product Protection

First, what does your product need? A heavy item needs strong, thick paperboard, while a delicate glass bottle needs a custom insert to prevent movement. Paper boxes are great protectors, but their strength is limited. Once, a client insisted on a thinner paper to save costs for their ceramic mugs. The samples looked great, but the first shipment resulted in a 20% breakage rate. We had to switch to a thicker, corrugated material. Always prioritize protection over small cost savings.

Brand Storytelling

Second, what story does your brand tell? Your packaging is often the first physical interaction a customer has with your brand. The materials3, colors, and graphics should all align with your brand's personality. Paper boxes are fantastic for this because they are like a blank canvas. You can print vibrant designs, use elegant foils, or choose a raw, recycled paper for an eco-conscious look.

The Customer Experience

Finally, think about the customer. How will they open it? Is it a frustrating struggle or a delightful reveal? The unboxing experience is a huge part of modern e-commerce. A well-designed box that is easy to open and feels good in the hands can leave a lasting positive impression. But remember paper's biggest weakness: water. If your product is shipping through humid climates, you may need to add a protective layer.

How does packaging design work?

Are you confused about the steps involved in the packaging design process6? Not understanding the workflow can cause delays, miscommunication, and a lot of frustration. Let me break it down for you.

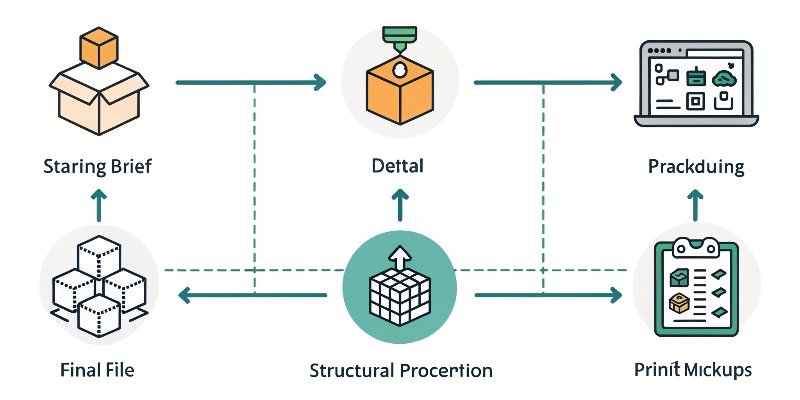

The packaging design process6 begins with a detailed brief to understand your goals. Next, designers create structural concepts (dielines) and visual concepts. After you approve 2D and 3D mockups, a final, print-ready file is prepared. This file is then used to create your physical sample.

As a manufacturer, I’ve guided thousands of projects through this process. It's a collaborative dance between the client and the designer, and clear communication is key. At Giftspack, we follow a structured path to make sure nothing gets missed. For a designer like Peter, understanding this from a supplier's side is incredibly valuable.

Here is the typical flow:

-

Briefing & Consultation: It all starts with a conversation. We need to understand your product, your brand, your target audience, and your budget. We discuss materials3, styles, and any special requirements. The more detail you provide here, the smoother the process will be.

-

Structural Design (Dieline Creation): This is the engineering phase. Our structural designer creates a 2D template, known as a dieline. This flat outline shows all the cuts, creases, and folds needed to build your box. We ensure it's sized perfectly for your product and is efficient to produce.

-

Graphic Design: Once the structure is approved, your graphic designer can place artwork onto the dieline template. This is where your brand comes to life with logos, colors, images, and text.

-

Mockup & Review: We will usually create a digital 3D mockup so you can see how the final box will look. For complex projects, we might create a blank structural sample first. This lets you test the fit with your product before we move to printing.

-

Finalization & Pre-press: After you approve everything, we prepare the final, print-ready artwork. Our pre-press team checks it for any technical issues to ensure it will print perfectly. This file is what we use to make your full, printed sample.

How do you test packaging?

Your sample looks great, but will it survive the real world? A package that fails during shipping means damaged products, lost revenue, and unhappy customers. You need to run these essential tests.

You test packaging by checking everything. First, check the visuals: print color, alignment, and material quality. Then, check the structure: dimensions, fit, and ease of assembly7. Finally, perform stress tests8 like drop tests9 and stacking tests10 to simulate real-world shipping and handling conditions.

Your approved sample is the "master copy" for your entire order. If it's not perfect, your whole batch won't be either. When that sample arrives, it’s time to become your own toughest quality inspector. Over my career, I've developed a checklist that I share with every client. It's simple but covers all the critical areas that can make or break your packaging. Don't just look at it and say "it looks nice." You have to put it through its paces.

Visual and Quality Inspection

This is the first thing you'll do. Get your design files and any color codes (like Pantone numbers) ready.

- Color Accuracy: Do the printed colors match your brand colors exactly?

- Print Quality: Is the text sharp? Are there any smudges or blurry areas? Is everything aligned correctly?

- Material Finish: Is the texture and finish of the paper what you expected?

Structural and Fit Test

This checks if the box actually functions as intended.

- Assembly: Fold the box together. Does it assemble easily? Do the flaps and tucks lock securely?

- Product Fit: Place your product inside. It should be snug, not too tight or too loose. If you have inserts, make sure they hold the product firmly.

- Dimensions: Use a ruler or calipers to check that the final folded dimensions match the specifications.

Performance and Stress Testing

This simulates the journey from the warehouse to the customer's doorstep.

- Drop Test: Put your product inside, tape the box shut, and drop it. Drop it from waist height onto its corners, edges, and flat sides. Does it hold up? Does the product inside survive?

- Stacking Test: If your boxes will be stacked in a warehouse, put some weight on top of one for 24 hours to see if it crushes.

| Test Type | What to Check | Why It's Important |

|---|---|---|

| Visual Check | Colors, print quality11, alignment | Ensures brand consistency and professional appearance. |

| Fit Check | Product fit, ease of assembly7 | Guarantees the box is functional and protects the product properly. |

| Drop Test | Box integrity, product safety after falls | Simulates accidental drops during shipping and handling. |

| Stacking Test | Resistance to crushing under weight | Ensures boxes won't be damaged when stored or shipped on pallets. |

Conclusion

Getting your custom sample right is key. By carefully checking the design, materials3, and performing real-world tests, you ensure your final packaging protects your product and perfectly represents your brand.

-

Customized packaging can significantly enhance your brand identity and product appeal. ↩

-

Unique dimensions can optimize product protection and presentation; learn how to implement them. ↩

-

Choosing the right materials can enhance your packaging's durability and aesthetic appeal. ↩ ↩ ↩ ↩

-

Creating a memorable unboxing experience can boost customer satisfaction and brand loyalty. ↩

-

Sustainable packaging design is increasingly important; discover how to align your packaging with eco-friendly practices. ↩

-

Understanding the packaging design process helps streamline production and improve outcomes. ↩ ↩

-

Understanding assembly ease can improve the customer experience and reduce production errors. ↩ ↩

-

Stress tests are vital for ensuring packaging durability during shipping and handling. ↩

-

Drop tests simulate real-world conditions, ensuring your packaging protects the product effectively. ↩

-

Stacking tests help ensure your packaging can withstand weight during storage and transport. ↩

-

High print quality is essential for brand representation; learn how to achieve it. ↩