Your beautiful cosmetic packaging looks amazing in photos. But will it get noticed and survive on a busy retail shelf? It's a common worry that can lead to lost sales.

To make your cosmetic packaging retail-ready, focus on four key areas. First, ensure the structural design is durable for shipping and display. Second, use compelling visual elements to attract customers. Third, choose materials and finishes that convey quality. Finally, verify all packaging meets regional retail and legal standards.

Getting a product onto a retail shelf is a huge milestone. I've seen so many brands achieve this, only to stumble at the final step. Their packaging either gets damaged in transit or simply fails to connect with shoppers in that split second of decision-making. The good news is that avoiding these pitfalls is straightforward if you know what to focus on. It’s a process I’ve guided countless clients through. Let’s break down exactly what you need to do to ensure your packaging not only reaches the shelf but flies off it.

How Does Structural Design Impact Retail Readiness?

You spent months perfecting a box design. But when it arrives at the store, the corners are crushed, and it looks cheap. This damages your brand reputation before anyone even tries the product.

A strong structural design is critical for retail success. It protects your product during shipping and handling. It also ensures your box stands correctly on the shelf and provides a positive unboxing experience, which builds customer loyalty.

Over my 16 years in this industry, I've learned that structure is the foundation of good packaging. A pretty box is useless if it can't do its primary job: protect the product. When we talk about structure, we’re talking about more than just a box. We’re considering the entire journey. It starts with the right material thickness, measured in GSM (grams per square meter). A flimsy paperboard might work for a lightweight lip balm, but a heavy glass jar of cream needs something much sturdier, like a rigid box.

I remember a client with a beautiful but delicate glass serum bottle. Their first packaging attempt resulted in a 15% breakage rate during shipping. We solved it by creating a custom-designed insert inside a reinforced tuck-end box. The insert held the bottle securely, and the stronger box withstood the bumps of transit. Problem solved.

It's also about how the package functions in the store and at home.

Key Structural Considerations

- Box Style: Does it need to hang on a hook or stand on a shelf? A straight tuck-end box is great for shelves, while a box with a hang tab is better for peg displays.

- Durability: The package must survive being stacked in a warehouse and handled by staff and customers.

- Unboxing Experience: The structure should make it easy and satisfying for the customer to open.

Here is a simple breakdown of common box styles for cosmetics:

| Box Style | Best For | Key Feature |

|---|---|---|

| Tuck End Box | Serums, Creams, Lipsticks | Cost-effective and versatile. |

| Rigid Box | Luxury Sets, Perfumes | Provides a premium feel and maximum protection. |

| Sleeve Box | High-end single items | Adds an extra layer of branding and experience. |

| Mailer Box | E-commerce, Subscription boxes | Extremely durable for direct shipping. |

Always, always get a physical prototype. Test it. Ship it to yourself. See how it holds up. This small step can save you a fortune.

What Are The Essential Visual Elements for Standing Out on Shelves?

Your product is fantastic, but it's sitting on a shelf next to dozens of competitors. Shoppers walk right past it because it simply doesn't catch their eye. Your hard work becomes invisible.

To stand out, you need a clear brand logo, easy-to-read product information, and a captivating color palette. A strong visual hierarchy guides the customer's eye, making your product instantly recognizable and desirable among a sea of options.

Think of a retail aisle as a loud, crowded party. Your packaging needs to be the person that effortlessly draws attention without shouting. You have about three seconds to make an impression. In that time, a customer's brain asks three questions: What is this? Who makes it? And why should I care? Your visual design must answer these instantly. This is where visual hierarchy comes in. It’s the art of arranging elements to show their order of importance.

Your brand name or logo should be prominent. Next, the product name—"Hydrating Face Serum," for example—must be crystal clear. Then, the key benefit, like "With Hyaluronic Acid" or "All-Day Moisture." I once worked with a startup that had a busy, artistic design. It was beautiful, but shoppers were confused about what the product actually did. We simplified the front panel, moving the complex design to the sides and focusing the front on the brand, product name, and main benefit. Sales increased by 30% in the next quarter. The lesson was simple: clarity sells.

Creating a Visual Hierarchy

- Logo Placement: Typically at the top or center. It builds brand recognition.

- Product Name: This should be the most legible text on the package. Use a clean, bold font.

- Key Benefits: Use bullet points or icons to highlight 2-3 main selling points. Don't overload it with text.

- Color and Imagery: Your color scheme should align with your brand identity (e.g., green for natural, gold for luxury). Imagery should show the product's texture or key ingredients.

Use contrast to your advantage. A dark box with metallic gold text creates a sense of luxury and is easy to read. A minimalist white box with a single pop of bright color can feel modern and clean. Your visuals are your silent salesperson on the shelf; make sure they are communicating the right message.

How Do Material Choices and Finishes Affect Consumer Perception?

Your packaging design looks great, but the box feels thin and cheap in a customer's hands. This disconnect between look and feel can make your entire product seem low-quality, killing the sale.

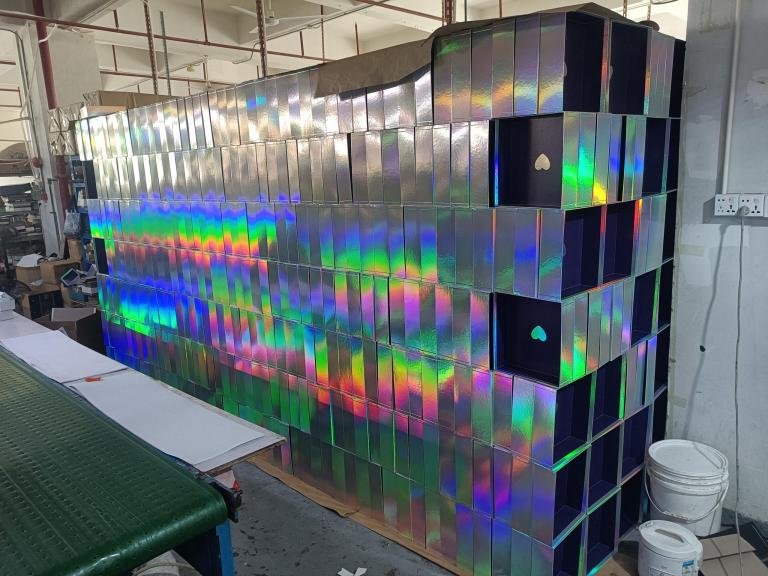

Materials and finishes directly influence perceived value. A thick, soft-touch paper feels more luxurious than thin, glossy cardstock. Finishes like embossing or foil stamping signal premium quality and can make a customer feel they are buying something special.

Packaging is a sensory experience. What a customer sees is only half the story; what they feel is just as important. The weight and texture of a box can say "luxury" or "budget" before they even read a word. At Giftspack, we guide our clients to think about the "handfeel" of their packaging from day one. I've seen a simple switch from a standard 300 GSM C1S paperboard to a 350 GSM soft-touch laminated board completely transform a product's shelf presence. It just feels more substantial.

Special finishes are like the jewelry of your packaging. They add that final touch of class.

Popular Finishes and Their Impact

- Foil Stamping: Using metallic foil (gold, silver, rose gold) adds a touch of elegance and luxury. It's perfect for logos or key design elements.

- Embossing/Debossing: This technique raises (emboss) or recesses (deboss) parts of the design, adding a three-dimensional texture that invites touch.

- Spot UV: Applying a high-gloss varnish to specific areas creates a stunning contrast with a matte background. It makes logos or images pop.

- Lamination: A thin film applied to the paper. Matte lamination gives a smooth, sophisticated feel, while gloss lamination makes colors vibrant and adds protection.

A few years ago, we helped a brand launch a new facial oil. The box was a simple black design. To elevate it, we added a subtle, embossed pattern of a leaf on the side and used gold foil for the logo. When customers picked it up, they could feel the texture and see the shimmer of the foil. It communicated "natural" and "premium" at the same time. These small details make a big difference in how your brand is perceived.

How Can You Ensure Your Packaging Meets Regulatory Requirements?

Your packaging is designed, produced, and ready to ship. Then, a retailer rejects it because it's missing a specific symbol or the ingredient list is in the wrong format. It's a costly and frustrating mistake.

To ensure compliance, you must research and include all mandatory information for the regions where you'll sell. This includes ingredient lists, net weight, country of origin, and specific warning labels. Partnering with an experienced packaging supplier can help you navigate these complex rules.

Compliance isn't the most glamorous part of packaging design, but it is one of the most important. Getting it wrong can lead to your products being pulled from shelves or even legal fines. The rules can be very different between countries. For example, the EU has strict regulations on allergen listings, while the US FDA has its own set of rules for labeling. For a designer like Peter, who may be creating packaging for global brands, this is a major challenge.

I always tell my clients to create a compliance checklist early in the design process. Don't leave it until the end. This includes things like the INCI (International Nomenclature of Cosmetic Ingredients) list, which must be in a specific order. You also need symbols like the Period After Opening (PAO) symbol, which looks like an open jar and tells the customer how long the product is safe to use after opening.

Key Compliance Checklist Items

- Ingredient List (INCI): Must be formatted correctly and in descending order of concentration.

- Net Weight/Volume: Clearly stated (e.g., 50 mL / 1.7 Fl. Oz.).

- Country of Origin: "Made in [Country]".

- Manufacturer/Distributor Address: A physical address or website.

- Required Symbols: This includes the PAO, recycling symbols, and any specific warning icons.

- Barcode (UPC/EAN): Essential for retail scanning and inventory management.

A reliable packaging partner should have experience with this. At Giftspack, we often review our clients' artwork to flag potential compliance issues before production begins. It's much easier to add a missing symbol in the design phase than to reprint ten thousand boxes. Don’t treat compliance as an afterthought. Build it into your design from the start.

Conclusion

Making your cosmetic packaging retail-ready combines art and science. It requires balancing a durable structure, eye-catching visuals, premium materials, and strict compliance to succeed in a competitive market.