Your packaging design looks perfect, but the sample box is too tight. Now you face costly delays and material waste. Getting the measurements right from the start is absolutely critical.

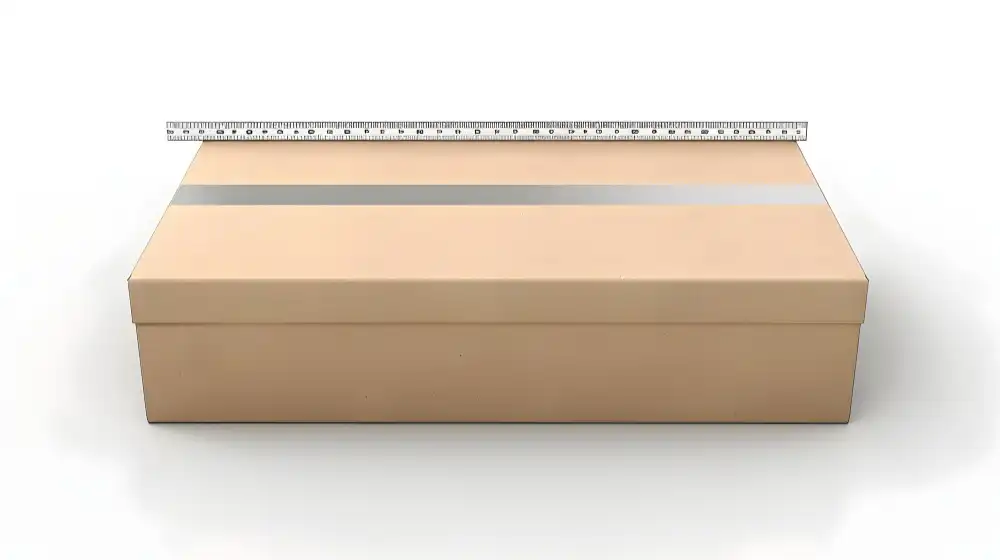

To measure a shoe box, first determine if you need internal or external dimensions. For product fit, measure the inside length, width, and height. For shipping and logistics, measure the outside. Use a rigid ruler or measuring tape and record the dimensions as Length x Width x Height.

Getting the measurements right seems simple, but it's a step where many projects go wrong. I've seen it happen many times over my 16 years in this business. A millimeter of difference can be the line between a snug, protective fit and a product that rattles around, or worse, a box that won't even close. This is especially true when you're working with custom designs where every detail matters. To really master this, we need to break down not just the "how," but the "why" behind each measurement. Let's get into the details that separate amateur attempts from professional, production-ready specifications.

What Are the Key Dimensions for Measuring Any Box?

Struggling to define your box dimensions? You know you need Length, Width, and Height, but which side is which? This confusion can lead to incorrect quotes and faulty prototypes.

The standard formula is always Length (L) x Width (W) x Height (H). The Length is the longest side of the opening. The Width is the shorter side. The Height (or Depth) is the distance from top to bottom when the box is closed.

When I first started in packaging, this was one of the first lessons I learned. It's the universal language of box making. For a designer like Peter, communicating these dimensions correctly to the production team is non-negotiable. It avoids any ambiguity. Let’s break it down further so it becomes second nature.

Understanding the Order: L x W x H

The sequence isn't arbitrary; it's an industry standard that ensures everyone is on the same page.

- Length: When you look at the box's main opening from above, this is the longest dimension.

- Width: This is the shorter dimension of the same opening.

- Height: Also called Depth, this is the measurement perpendicular to the length and width. It's how "tall" the box is.

Here's a simple table to visualize it for common box types:

| Box Type | How to Identify Length & Width | Common Use |

|---|---|---|

| Shoe Box | Longest side of the lid's opening is Length. | Retail, Apparel Boxes |

| Mailer Box | Longest side of the front flap is Length. | E-commerce, Subscription Boxes |

| Shipping Carton | Longest side of the top flaps is Length. | Logistics, Bulk Transport |

Sticking to this L x W x H standard is the first step toward flawless packaging production. It removes guesswork and ensures that the die-lines created by the design team match the final product perfectly.

How Do Internal and External Measurements Affect Your Design?

You gave the factory your product's exact size, but it doesn't fit in the box. This happens when you don't account for the box material's thickness. It's a frustrating and preventable error.

Internal dimensions (the "usable space") are for ensuring your product fits snugly inside. External dimensions are for calculating shipping costs, pallet stacking, and retail shelf space. The difference between them is the thickness of the packaging material itself.

This is a detail that often trips up newcomers. They measure their product and order a box with those exact dimensions, forgetting the box walls have thickness. For our designer, Peter, this is a critical calculation. The choice of material directly impacts the difference between the inside and outside measurements. A thin paperboard box will have a much smaller difference than a thick, heavy-duty corrugated mailer. That difference, called "material allowance," is everything. It ensures that the Custom Rigid Boxes we create provide a premium unboxing experience, not a struggle to get the product out.

The Importance of Material Allowance

Material thickness is the key factor. You can't just add a random number; you need to know your material.

- Paperboard: Typically 0.010" to 0.024" (or 10 to 24 points). The difference between internal and external dimensions is small but still important for a perfect fit.

- Corrugated Board: Varies by flute size (e.g., E-flute is ~1.6mm, B-flute is ~3.2mm). For a B-flute box, the external dimensions could be over 6mm larger than the internal ones.

Let's look at a practical example:

| Measurement Type | Purpose | Key Consideration |

|---|---|---|

| Internal Dimensions | Product Fit. Does the shoe, with its tissue paper, fit inside without being crushed? | Add a small "ease" allowance (e.g., 2-3mm) to the product's dimensions for easy removal. |

| External Dimensions | Logistics. How many boxes fit on a pallet? What is the shipping volume (dimensional weight)? | This is the number shipping carriers use to calculate costs. Accuracy here saves money. |

For every project, we start by defining the internal dimensions based on the product. Then, we add the material allowance to calculate the external dimensions for our shipping and logistics partners. Getting this right is fundamental to efficient and cost-effective packaging.

What Tools and Techniques Guarantee Measurement Accuracy?

Using a flexible sewing tape to measure a box seems fine, right? But its flexibility can introduce small errors that become big problems during mass production. Inaccurate tools lead to inaccurate results.

For the highest accuracy, always use a rigid tool like a steel ruler or a carpenter's tape measure. Measure on a flat surface, take each measurement twice, and record the dimensions in millimeters or to the nearest 1/16th of an inch.

In my workshop, we live by the rule: "measure twice, cut once." This applies just as much to box design as it does to carpentry. A small error of 2mm on a single box might seem trivial. But when you're producing 10,000 units, that error can lead to a massive waste of materials, time, and money. It can also compromise the structural integrity of the box. That’s why we insist on using the right tools and a consistent method. It's about building a process that eliminates guesswork and ensures every single box is perfect, whether it's a simple folding carton or a complex Magnetic Closure Box.

Pro-Tips for Flawless Measurement

Here are some techniques we use at Giftspack to ensure our measurements are always spot-on:

- Use the Right Tool: A rigid steel ruler is best because it won't bend or stretch. A retractable metal tape measure is a good second choice. Avoid cloth tapes or plastic rulers.

- Measure an Assembled Box: If you have a sample, measure a fully assembled box. Measuring a flat, unfolded die-line is for verifying production specs, not for determining the initial fit.

- Measure from the Middle: Don't measure right at the edge or corner, where the material might be slightly compressed or flared. Measure from the center point of a panel to the opposite center point for the most reliable reading.

- Round Up, Not Down: If your measurement falls between two marks, it's often safer to round up to the next millimeter or 1/16th of an inch. A little extra space is usually better than not enough.

By following these simple but crucial techniques, designers like Peter can be confident that the dimensions they provide will result in packaging that functions exactly as intended, protecting the product and enhancing the brand's reputation.

Conclusion

In summary, accurate measurement is the foundation of successful packaging. Master the difference between internal and external dimensions, use the right tools, and always follow the L x W x H standard.