Struggling with inconsistent packaging quality? Poorly made boxes can damage your product and brand reputation. We ensure reliability with strict quality checks at every stage of the process.

A reputable custom packaging company ensures quality and reliability through a multi-stage system. This includes inspecting all raw materials, getting client approval on a pre-production sample, conducting in-process checks during manufacturing, and performing a final audit before shipping. This guarantees consistency from the first box to the last.

It's great that you're asking about quality. It shows you care deeply about your brand's image. In my 16 years in the packaging industry, I've learned that reliability is never an accident. It's the result of a deliberate, well-managed system. A single weak point can compromise an entire shipment. Let's break down exactly how we build that system to deliver consistent results, starting with how a box is put together. You will see how paying attention to the small details makes a huge difference.

How do you ensure accuracy and quality when assembling packing products?

Worried that manual assembly will lead to sloppy folds or weak seams? These small errors can cause big problems for your customers. We prevent this by combining skilled teamwork with precise machinery.

We ensure assembly accuracy with Standardized Operating Procedures (SOPs)1, custom jigs2 for consistent folding, and automated glue systems3. Our teams also constantly compare finished boxes against an approved master sample. This helps catch any deviation early and guarantees a perfectly assembled product every time.

Getting the assembly right is crucial. After all, a beautifully printed sheet of paperboard is useless if it's not folded and glued correctly. I always see assembly as a partnership between our people and our machines. Both have to work together perfectly to achieve the quality you expect.

The Role of People and Machines

I tell my team that a machine is only as good as the person running it. That's why we invest heavily in training. Every member of our assembly team is trained on our Standard Operating Procedures, or SOPs. Think of an SOP as a detailed recipe for each specific box design. It lists every step, every type of glue, and every checkpoint. This ensures that every worker builds the box in the exact same way, creating consistency across the entire production run. This human oversight is something a machine alone cannot replicate.

Tools for Precision

To help our team, we use tools that guarantee precision. Jigs and fixtures are custom-made guides that hold the box parts in place during assembly. This ensures every fold is perfectly aligned and every corner is a sharp 90-degree angle. For a box with a magnetic closure, for example, a jig holds the flaps in the perfect position while the glue sets. We also use automated gluing systems. This machinery applies the exact amount of adhesive in the precise location needed. It stops problems like weak seams from too little glue or messy-looking boxes from too much.

| Feature | Manual Assembly | Machine-Assisted Assembly |

|---|---|---|

| Speed | Slower, depends on worker skill | Much faster and consistent |

| Precision | Can vary slightly | Extremely high and repeatable |

| Flexibility | Good for complex, small runs | Best for standardized, large runs |

| Cost | Higher labor cost per unit | Lower cost per unit at scale |

What are the quality control system4s for packaging?

You’ve approved a perfect sample. But how do you know the final 10,000 units will look just as good? Inconsistencies can disappoint customers and hurt your brand. A multi-stage quality control system4 is the only way to guarantee consistency.

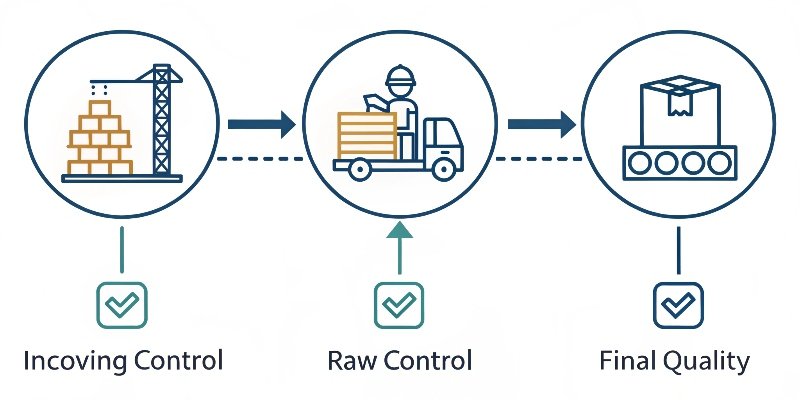

A complete quality control system for packaging has three main stages. It begins with Incoming Quality Control (IQC) for raw materials. It continues with In-Process Quality Control (IPQC) during production. It ends with a Final Quality Control (FQC) audit before the order is shipped.

A good quality control (QC) system is like a series of gates. A product cannot pass to the next stage of production unless it meets the standards at the current gate. In my experience, waiting until the end to check for quality is a recipe for disaster. We have to check for it constantly.

Stage 1: Incoming Quality Control (IQC)5

This is our first line of defense. Before any material even enters our factory floor, it is inspected. We check the paperboard to make sure it's the correct thickness, stiffness, and GSM (grams per square meter). We verify that the color of the paper matches the client's specification. I remember one time we had to reject an entire shipment of paperboard because it had tiny, almost invisible flecks in it. For a standard shipping box, it might have been okay. But this was for a luxury cosmetics client, and those small flaws would have ruined the premium feel of their packaging.

Stage 2: In-Process Quality Control (IPQC)6

This happens while the boxes are being made. Our line supervisors and dedicated IPQC staff constantly pull random samples directly from the printing, die-cutting, and lamination machines. They use a spectrophotometer to check that print colors match the approved Pantone shades. They examine the die-cut lines to ensure they are crisp and clean. They test the lamination to make sure it’s properly adhered without any bubbles. Finding a problem here means we only have to fix a small part of the run, not the entire order.

Stage 3: Final Quality Control (FQC)7

This is the last checkpoint. Before an order is packed for shipment, our dedicated FQC team performs a final audit. They use a method called AQL (Acceptable Quality Limit) to randomly select a number of finished boxes to inspect. They go over every detail: construction strength, print quality, dimensions, and functionality. Only when the order passes this final, rigorous inspection is it approved to leave our facility.

Why is packaging important in quality assurance8?

You spend so much time and money perfecting your product. But what if it reaches the customer in a flimsy, damaged box? The customer's first impression is ruined, and they associate that poor quality with your product. Your packaging is the first quality promise you make.

Packaging is a vital part of quality assurance because it is the first physical interaction a customer has with your brand. It must protect the product from damage during shipping and handling. It also communicates your brand's standards. A quality box implies a quality product inside.

Many people think of quality assurance8 as only applying to the product itself. But I've learned that the packaging is just as important. It serves two key quality functions: it provides physical protection and it shapes customer perception. A failure in either of these areas is a failure for the brand.

The Protective Shell

First and foremost, the packaging is there to make sure the product arrives in perfect condition. This is its most basic quality-assurance job. Think about a delicate piece of electronics or a glass bottle of lotion. It needs to be protected from bumps, drops, and vibrations during its journey. We achieve this by carefully selecting the right grade of paperboard and designing custom inserts9 that hold the product securely. A crushed box often means a broken product and an unhappy customer. While paper boxes are not naturally waterproof, we can add laminations or special coatings to give them resistance to moisture, adding another layer of protection.

The Silent Salesperson

Second, the packaging communicates the quality of what's inside. As a designer like Peter knows, the "unboxing experience10" is a powerful marketing tool today. When a customer receives a package, the quality of that box sets their expectations. A box made from thick material, with sharp printing and perfectly aligned edges, tells the customer that this is a premium brand that cares about details. On the other hand, a flimsy box with faded colors immediately lowers the perceived value of the product inside, even if the product itself is excellent. It’s a key part of the overall quality promise.

Why is it important to have a good and quality standard packaging?

Cutting corners on packaging seems like an easy way to save some money. But this often costs you more in the long run. You end up dealing with product returns, damage claims, and lost customers. Investing in a good, quality standard for your packaging is an investment in your brand's future.

Good, quality standard packaging is crucial because it builds brand consistency, increases customer trust, and improves operational efficiency. Standardized boxes protect products reliably, simplify logistics and fulfillment, and create a professional brand image that customers recognize and value.

Having a "standard" for your packaging doesn't mean it has to be boring. It means having a consistent level of quality and a defined set of specifications for all your packaging. Over my career, I've seen brands thrive when they get this right. It improves everything from brand image to the bottom line.

Building Brand Consistency and Trust

When a customer buys your product more than once, they expect the same great experience every time. A quality standard for your packaging ensures this happens. The box will have the same color, the same feel, and the same strength whether they buy it today or a year from now. This consistency builds powerful brand recognition and trust. Think of the most famous brands in the world; you know their packaging instantly. That's not an accident. It's the result of strictly maintaining a quality standard.

Streamlining Your Operations

From a practical business view, standard packaging makes everything run more smoothly. Consistency helps your entire supply chain. Your fulfillment team knows exactly how to pack each box, which makes them faster and more efficient. Your shipping carriers can rely on the stated weights and dimensions, preventing surprise fees. Standardized box sizes also stack neatly in the warehouse and on shipping pallets, optimizing storage space. Trying to manage a dozen different low-quality box types is a logistical nightmare that costs time and money.

| Paper Box Packaging | Pros | Cons |

|---|---|---|

| Material | Eco-friendly and easily recyclable. | Not waterproof without special treatment. |

| Cost | Generally low manufacturing cost. | Can have limited strength for heavy items. |

| Logistics | Lightweight and ships flat to save space. | Can be crushed if not stacked properly. |

| Branding | Highly customizable with endless printing options. | May feel less luxurious than wood or metal. |

Conclusion

In short, quality is not a single action but a complete system. It covers everything from raw materials to final assembly. Reliable packaging protects your product, strengthens your brand, and keeps your customers happy.

-

Understanding SOPs can enhance your packaging quality and consistency, ensuring a reliable product. ↩

-

Explore how custom jigs can enhance precision in packaging assembly, leading to better product quality. ↩

-

Learn how automated glue systems can improve efficiency and reduce errors in packaging assembly. ↩

-

Discover the importance of a quality control system in maintaining high packaging standards. ↩ ↩

-

IQC is crucial for ensuring raw materials meet quality standards before production begins. ↩

-

IPQC helps catch issues during production, ensuring a higher quality final product. ↩

-

FQC is the last step to ensure that only the best products are shipped to customers. ↩

-

Quality assurance in packaging protects your product and enhances customer perception. ↩ ↩

-

Custom inserts provide protection and enhance the presentation of your products. ↩

-

The unboxing experience can significantly impact customer satisfaction and brand loyalty. ↩