Your product rattles in the box, risking damage and a cheap first impression. You need a secure, premium feel, but complex solutions seem too expensive. How do you fix this?

Cosmetic box inserts are essential. They secure products, preventing movement and breakage during shipping. They also create an organized, high-end presentation that significantly boosts brand perception and the customer's unboxing experience.

Throughout my 16 years in the packaging industry, I have seen inserts transform simple boxes into premium brand experiences. They are not just filler material; they are a critical part of your product's journey and story. Getting the insert right means your product arrives safely and impresses the customer from the moment they open the box. Let's look closer at how they work and what options you have. You will see how choosing the right insert can make a massive difference for your brand.

What Are the Best Materials for Protective Cosmetic Inserts?

Choosing the wrong insert material can lead to damaged goods and unhappy customers. You need reliable protection that looks professional without destroying your budget. What is the best choice available?

The best material depends on your specific product and brand goals. EVA foam offers premium, shockproof protection. Molded pulp is a great eco-friendly option. Paperboard is versatile and cost-effective. Each provides a different mix of security and style.

Finding the right material is a balance. As a packaging designer, you have to weigh protection, aesthetics, sustainability, and cost. Over the years, I've worked with many materials, and a few stand out for cosmetics.

EVA Foam

For high-end, fragile items like glass serum bottles or heavy perfume containers, I almost always recommend EVA foam. It’s dense, great at absorbing shock, and has a smooth, premium feel. We can cut it precisely to fit any shape, holding the product tightly in place. The downside is that it's one of the more expensive options and not the most environmentally friendly, but for luxury protection, it is unmatched.

Molded Pulp

If your brand has a strong eco-conscious message, molded pulp is an excellent choice. It’s made from recycled materials like paper or bamboo and can be molded to fit your products perfectly. It provides good protection and has a natural, earthy texture. I've used it for organic skincare brands, and it reinforces their commitment to sustainability.

Paper and Cardboard

This is the most common and versatile option. It’s affordable, recyclable, and offers endless design possibilities. We can die-cut it into complex shapes and print graphics directly on it. For a designer, this is like a blank canvas. We can create layered designs or intricate pop-up features. It offers good protection for many items, especially when designed with clever folds for extra rigidity.

| Material | Protection Level | Cost | Aesthetic |

|---|---|---|---|

| EVA Foam | High | High | Premium, Modern |

| Molded Pulp | Medium-High | Medium | Natural, Eco-Friendly |

| Paper/Cardboard | Medium | Low | Highly Customizable |

How Can Inserts Elevate the Unboxing Experience?

Your product arrives, but the unboxing feels cheap and disorganized. That crucial first impression is lost, and the customer feels underwhelmed. How do you create that memorable "wow" moment?

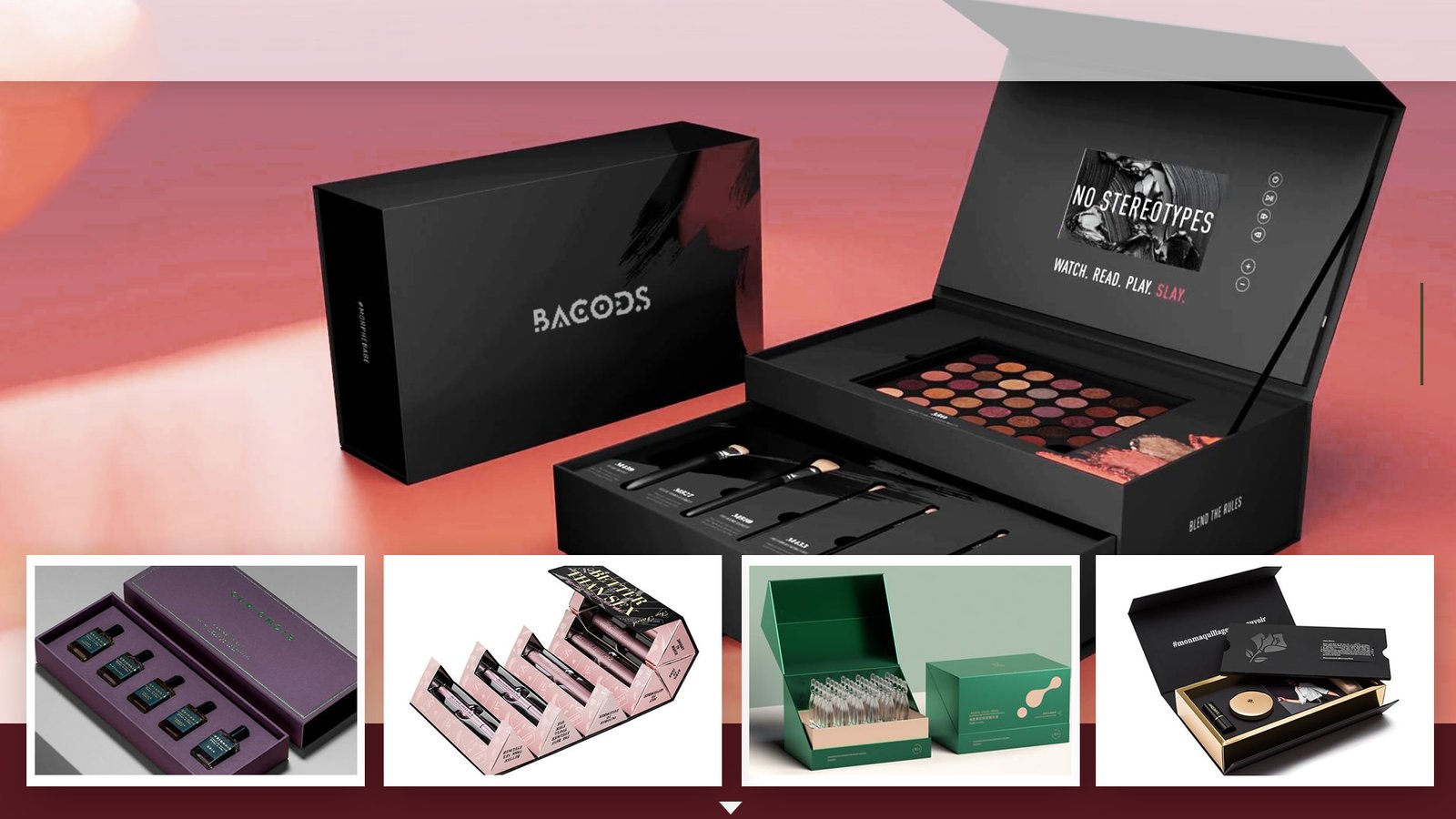

Inserts create a structured and luxurious reveal. They hold each item perfectly in place, creating a neat, organized display. This thoughtful presentation makes the product feel more valuable and turns a simple opening into a memorable brand experience.

Unboxing is your first, and sometimes only, physical interaction with an online customer. An insert does more than just hold things; it sets the stage. It's a key tool for storytelling and adding perceived value. From my experience, a great insert focuses on three areas.

Creating a Visual Journey

A well-designed insert guides the customer's eyes. It presents the products in a deliberate order, building excitement. I remember a project for a multi-product beauty set. We designed a layered insert. The customer lifted the top layer holding the main product to reveal smaller, complementary items underneath. It created a sense of discovery and made the whole package feel more substantial and thoughtful. This turns unboxing from a task into an engaging process.

Adding Functional Value

Inserts can do more than just hold items. You can print instructions, brand stories, or a thank-you message directly onto the insert. I’ve seen some really creative uses, like including a QR code that links to a video tutorial. We once designed an insert for a face roller that could be easily folded to become a stand for the product on a vanity. This adds real, lasting value beyond the initial unboxing and keeps your brand visible.

Reflecting Brand Identity

The material, color, and finish of the insert should reflect your brand. A minimalist, clean-tech brand should use a simple, white paperboard insert with precise cuts. A glamorous, luxury brand might use a black insert with a soft-touch or velvet finish. Consistency is key. The insert must feel like it belongs to the same family as the outer box and the product inside. This reinforces your brand identity at every touchpoint.

How Do You Balance Cost, Protection, and Aesthetics with Inserts?

You want a beautiful, protective insert, but the budget is tight. Sacrificing one element for another feels like a compromise you shouldn't have to make. How do you find that perfect sweet spot?

Start by defining your single highest priority. For fragile glass, prioritize protection with foam. For mass-market items, focus on cost with clever cardboard designs. You can then enhance aesthetics with smart, low-cost details like precise cuts or minimal printing.

This is the classic challenge every packaging designer faces. The good news is, you don't always have to make a hard compromise. It's about being strategic and creative. I guide my clients through a simple, three-step thought process.

Step 1: Define Your "Must-Have"

First, decide what is non-negotiable. If you are shipping a

$100 serum in a glass bottle, your "must-have" is protection. The product cannot break. This means you should allocate more of your budget to protective materials like EVA foam. If you're selling a solid lipstick in a sturdy tube, protection is less of a concern. Your "must-have" might be aesthetics or cost. This single decision will guide all your other choices.

Step 2: Make Smart Material and Design Choices

Once you know your priority, you can get creative. If cost is the main driver, paperboard is your best friend. As a designer, you can make a simple cardboard insert look amazing with structural design. Use folds and multi-level cuts to create a sense of depth and quality without adding cost. I once worked with a client to redesign their insert from a two-piece assembly to a single, intricate die-cut piece. It saved them 30% on material and assembly costs while looking more custom and high-end.

Step 3: Use Design for Efficiency

Think about how the insert will be produced. A design that minimizes waste from a sheet of paperboard is more cost-effective and sustainable. Avoid complex glue points if you can use clever tucks and folds instead. A simple design can often look more elegant and modern than something overly complex. For example, instead of a full-color print, consider a simple foil stamp logo in one key spot. It adds a touch of luxury for a fraction of the cost of a full print job. This intelligent approach delivers on all fronts: cost, protection, and a great look.

Conclusion

Cosmetic inserts are vital for protecting products and creating a memorable unboxing. Choosing the right material and design is key to balancing cost, safety, and your unique brand aesthetic.