In the world of product packaging, inserts play a crucial role in protecting, organizing, and enhancing the presentation of your products. Whether you're packaging electronics, cosmetics, or food items, choosing the right type of insert can make a significant difference in the overall packaging experience. In this comprehensive guide, we'll explore various types of inserts available for your product packaging and how they can benefit your business.

Understanding Inserts: An Overview

What Are Inserts?

Inserts are additional components placed inside product packaging to serve various purposes, such as cushioning fragile items, organizing multiple products, or enhancing the aesthetic appeal of the packaging.

Importance of Inserts in Product Packaging

Protection and Security

Inserts provide an additional layer of protection to products during shipping and handling, reducing the risk of damage or breakage. They help secure items in place and prevent them from shifting or moving around inside the packaging.

Organization and Presentation

Inserts help organize products neatly within the packaging, making it easier for customers to locate and access them. They also contribute to the overall presentation of the product, creating a visually appealing and professional-looking packaging design.

Types of Inserts

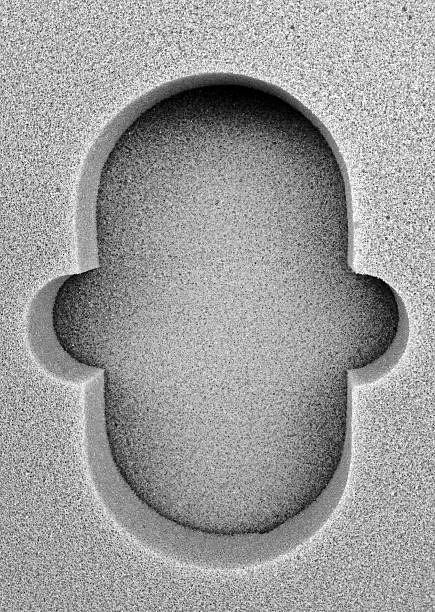

1. Foam Inserts

Foam inserts are soft and lightweight inserts made from foam materials such as polyethylene or polyurethane. They provide excellent cushioning and shock absorption, making them ideal for protecting delicate or fragile items during transit.

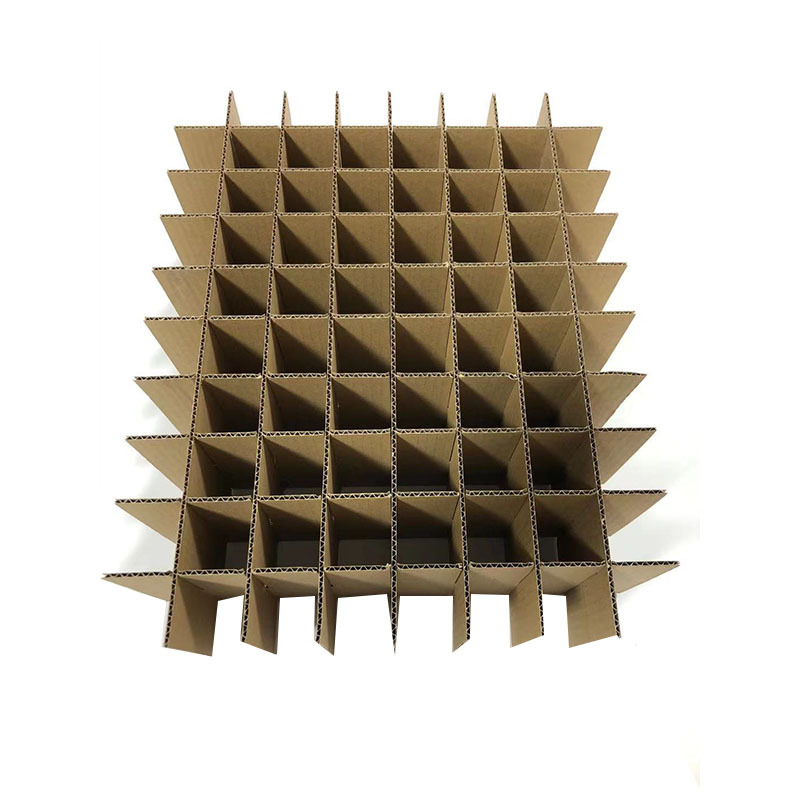

2. Cardboard Inserts

Cardboard inserts are rigid and sturdy inserts made from corrugated cardboard or solid paperboard. They offer structural support and stability to products and can be customized to fit the specific dimensions of the packaging.

3. Plastic Inserts

Plastic inserts are durable and versatile inserts made from materials like PVC, PET, or PP. They come in various shapes and sizes and can be molded to fit the contours of the product, providing a snug and secure fit.

4. Fabric Inserts

Fabric inserts are soft and flexible inserts made from materials such as felt, velvet, or satin. They add a touch of elegance and luxury to product packaging, making them ideal for high-end or luxury goods.

5. Molded Pulp Inserts

Molded pulp inserts are eco-friendly inserts made from recycled paper materials. They are molded to the shape of the product and offer excellent protection against impact and vibration during shipping.

Benefits of Using Inserts

- Enhanced Protection: Inserts help prevent damage to products during transit by providing cushioning and support.

- Improved Organization: Inserts help organize products neatly within the packaging, making it easier for customers to access them.

- Enhanced Presentation: Inserts contribute to the overall aesthetics of the packaging, creating a visually appealing and professional-looking design.

Conclusion

In conclusion, inserts play a vital role in product packaging by providing protection, organization, and enhanced presentation. Whether you choose foam inserts for fragile items, cardboard inserts for structural support, or fabric inserts for luxury goods, selecting the right type of insert can elevate your packaging and enhance the overall customer experience.

FAQs about Inserts for Product Packaging

- What are inserts in product packaging, and why are they important? Inserts are additional components placed inside product packaging to provide protection, organization, and enhanced presentation. They are important for securing products during transit and improving the overall packaging experience.

- What are the different types of inserts available for product packaging? Common types of inserts include foam inserts, cardboard inserts, plastic inserts, fabric inserts, and molded pulp inserts. Each type offers unique benefits and is suitable for different packaging requirements.

- How do inserts contribute to the protection of products during shipping and handling? Inserts provide cushioning and support to products, preventing them from shifting or moving around inside the packaging. This helps reduce the risk of damage or breakage during transit.

- Are inserts customizable to fit specific product dimensions? Yes, inserts can be customized to fit the specific dimensions of the product and packaging. This ensures a snug and secure fit, maximizing protection and presentation.

- Are there eco-friendly options available for inserts? Yes, molded pulp inserts are eco-friendly options made from recycled paper materials. They offer excellent protection and are biodegradable, making them a sustainable choice for product packaging.