Are you struggling to choose the right box for your product? The sheer number of options can be overwhelming, making it hard to find the perfect fit that protects and presents your brand.

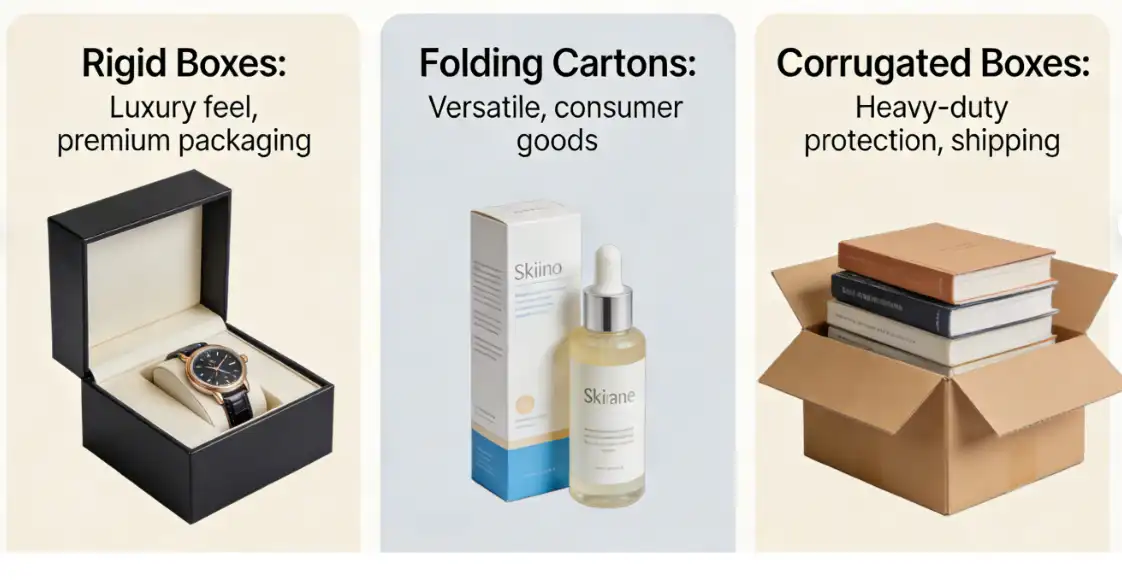

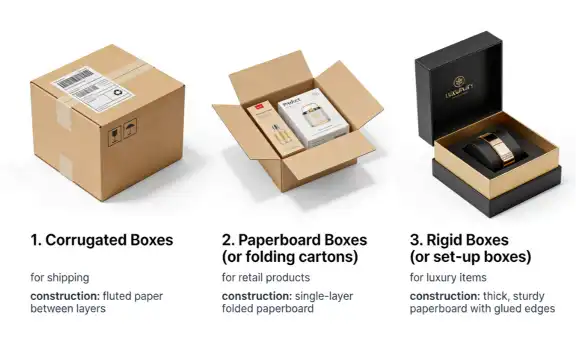

In my experience, the packaging world generally groups paper-based boxes into three main types: rigid boxes, folding cartons, and corrugated boxes. Each serves a different purpose, from creating a luxury feel to providing heavy-duty protection for shipping, ensuring there's a solution for nearly every product.

Choosing the right box type is one of the first, and most important, decisions a designer like Peter has to make. It sets the stage for the entire unboxing experience and determines how well the product is protected. Over my 16 years in this industry, I've seen firsthand how the right choice can elevate a brand, while the wrong one can lead to damaged goods and disappointed customers. Let's look closer at these fundamental categories to understand which one is right for you.

Do you know the key differences between box types?

Trying to figure out which box is which can be confusing. With so many terms floating around, it's easy to feel lost and unsure about what makes each type unique for your project.

The main differences lie in their material and construction. Folding cartons are lightweight paperboard, ideal for retail shelves. Rigid boxes are made of thick, non-bending paperboard for a premium feel. Corrugated boxes have a fluted layer for strength, perfect for shipping and protecting heavier items.

Digging into Box Materials and Styles

When I first started in packaging, I thought a box was just a box. But I quickly learned the nuances are what make or break a design. For a designer like Peter, understanding these differences is crucial. It’s not just about aesthetics; it's about function, cost, and the customer's experience.

Let’s break it down further. We have our main three categories, but within and beyond those, there's a whole world of options. You might encounter wooden or metal boxes for very high-end or industrial uses, but for most consumer products, paper is king. To make it clearer, here’s a simple table that lays out some common styles I work with regularly.

| Box Style | Material | Common Use Case | Key Feature |

|---|---|---|---|

| Folding Carton | Paperboard | Cereal boxes, cosmetic packaging | Ships flat, cost-effective for retail |

| Rigid Box | Condensed Paperboard | High-end electronics, luxury gifts | Sturdy, premium feel, doesn't collapse |

| Corrugated Box | Corrugated Fiberboard | Shipping boxes, e-commerce | High strength-to-weight ratio, protective |

| Auto-Lock Bottom | Paperboard/Corrugated | Fast-food, quick assembly | Snaps into place for fast packing |

| Telescoping Box | Paperboard/Corrugated | Shoe boxes, board games | Consists of a separate top and bottom |

Each style serves a specific need. An auto-lock bottom is a lifesaver for projects that require fast assembly on a packing line. On the other hand, a telescoping box offers a classic "unveiling" experience that's perfect for products like shoes or iPhones. Understanding these subtle but important distinctions is what separates a good design from a great one.

Have you heard of the three levels of packaging?

You've designed a great box, but then you hear terms like "primary" and "tertiary" packaging thrown around. It can be confusing and make you wonder if your single box is enough for the entire journey.

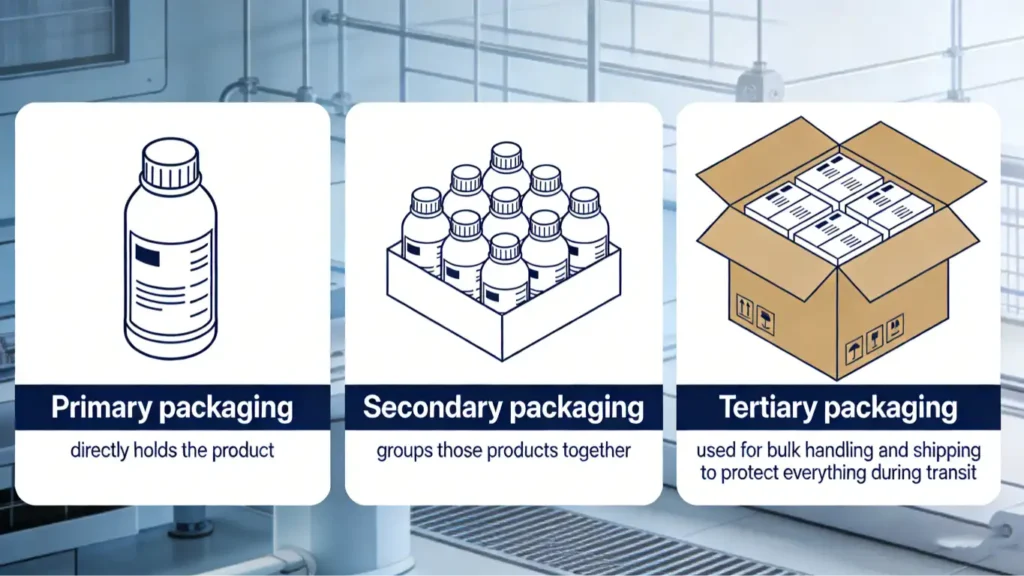

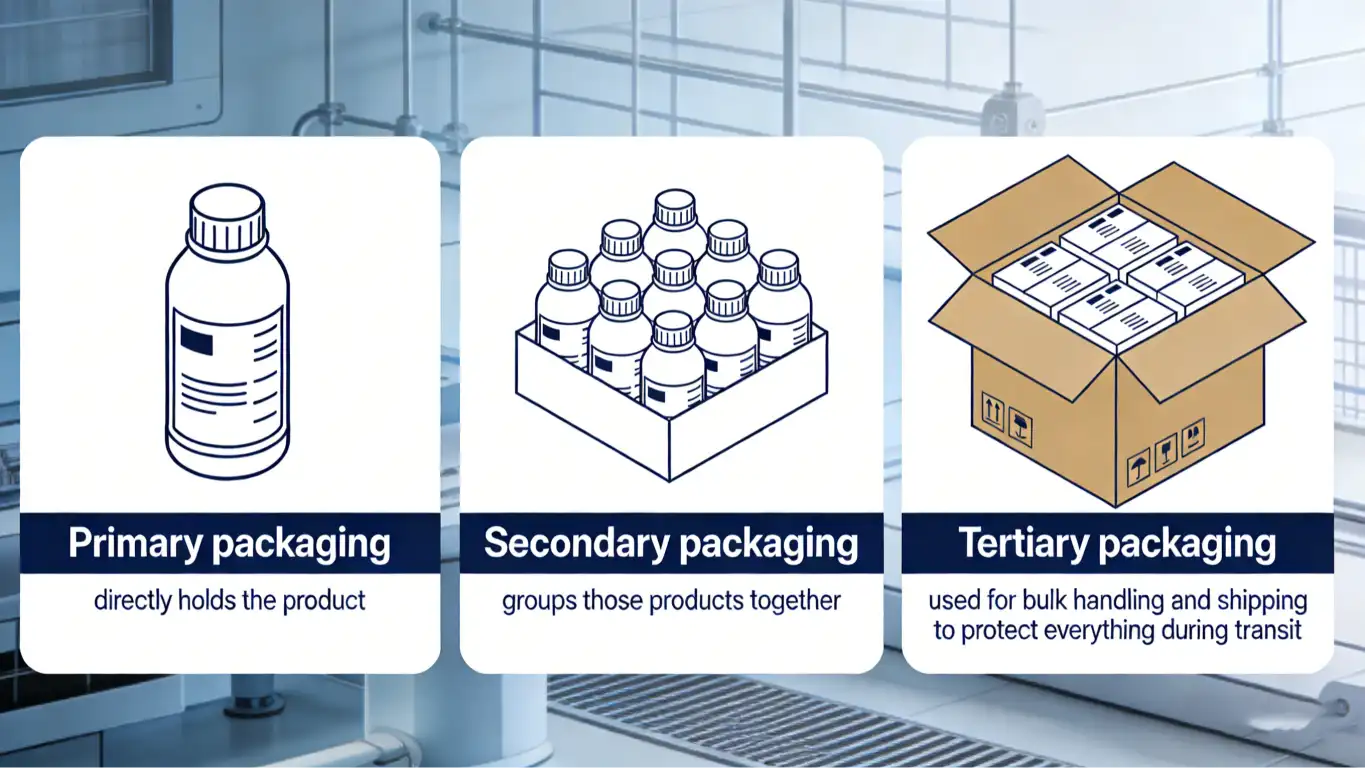

These terms simply refer to the different layers of packaging. Primary packaging is what directly holds the product. Secondary packaging groups those products together. Tertiary packaging is used for bulk handling and shipping to protect everything during transit.

From Product to Pallet: A Package's Journey

Understanding the "three packages" or levels is fundamental for any designer. It’s not just about the box the customer opens; it’s about how that box gets to them safely. I always walk Peter and his team through this journey to make sure we’re not missing anything.

-

Primary Packaging: This is the first layer touching your product. Think of the bottle for a soda, the wrapper for a candy bar, or the folding carton containing a tube of face cream. This level is all about protecting the product and marketing it to the consumer. It's your brand's first handshake.

-

Secondary Packaging: This is the next layer out. It groups several primary packages together. A great example is the paperboard box that holds six bottles of beer. For a retail setting, this layer is often designed to be put directly on the shelf, so it serves both a logistical and a marketing purpose. It needs to be easy for store employees to handle but also attractive to shoppers.

-

Tertiary Packaging: This is the outermost layer, designed for safe and efficient shipping. The most common example is a large corrugated box that holds multiple secondary packages. When you see a pallet of goods wrapped in plastic, that entire pallet is considered a unit of tertiary packaging. Here, the focus is purely on protection and logistics, not on consumer appeal. The design must be optimized for stacking strength and durability to withstand the rigors of transportation.

For Peter, this means thinking beyond that single, beautiful box. He has to consider how it will be grouped, shipped, and ultimately presented. A failure at any level can undermine the success of the whole product.

What are boxes used for?

You know the different types of boxes, but how do you decide which one to use for a specific purpose? A shipping box is obviously different from a gift box, but the lines can blur, causing uncertainty.

The function dictates the form. Shipping boxes (usually corrugated) prioritize protection and durability. Retail boxes (often folding cartons) focus on branding and shelf appeal. Gift boxes (typically rigid) aim to create a premium unboxing experience. Each use case demands different materials and structural designs.

Matching the Box to the Mission

When I consult with a designer like Peter, we don't just talk about what a box is; we talk about what it does. A box's job is its most important feature. The most beautiful design is useless if it fails at its primary function. Over the years, I've learned to categorize boxes by their mission, which helps clarify the design process immensely.

First, we have shipping and e-commerce boxes. Their main goal is protection. These are almost always corrugated because they need to withstand being dropped, stacked, and tossed around. The design challenge here isn't just about preventing damage but also about "right-sizing" to avoid high shipping costs from volumetric weight. For Peter, this means focusing on structural integrity and efficient use of space.

Next are retail boxes. These boxes live on a shelf and their job is to sell. This is where folding cartons shine. They offer a fantastic surface for high-quality printing, allowing for vibrant graphics and branding that grab a customer's attention. The design focus is on visual appeal, communicating product benefits, and fitting neatly into a retail display.

Then there are gift boxes and luxury packaging. These are usually rigid boxes, and their purpose is to create an experience. The weight, the texture, and the sound of the lid lifting off all contribute to a feeling of quality and anticipation. For these projects, I advise Peter to focus on the tactile elements and the unboxing sequence. It's less about cost-efficiency and more about conveying value.

Finally, we have storage boxes, like archive boxes. Functionality is everything here. They need to be sturdy enough for stacking, easy to label, and simple to assemble and break down. The design is utilitarian, prioritizing strength and ease of use over aesthetics.

What is a 3 cube box?

You're looking for moving supplies and see "3 cube box" listed. The term seems specific, but without context, it's just jargon that leaves you wondering if it's the right size for your needs.

A "3 cube box" simply refers to a box with a capacity of 3 cubic feet. It is a standard large-sized moving box, typically measuring around 18 x 18 x 16 inches, perfect for packing medium-to-large household items like appliances, pots, and toys.

Understanding Box Sizing by Volume

In the packaging and moving industry, we often talk in terms of cubic feet, or "cubes." It's a quick way to communicate a box's carrying capacity without getting bogged down in specific length, width, and height measurements every single time. When I'm working on a project that involves logistics, like helping a client create a kit of packaging for their customers to ship items back, this terminology is incredibly useful.

A "3 cube box" is one of the most common sizes you'll find. Its official volume is 3.0 cubic feet, and its dimensions are typically 18 inches long, 18 inches wide, and 16 inches high (18"x18"x16"). This makes it a versatile, large box that's ideal for packing items that are bulky but not excessively heavy. If you load it up with books, it will be too heavy to lift, but it’s perfect for things like:

- Small kitchen appliances

- Pots and pans

- Toys

- Lampshades

- Clothing

For a designer like Peter, understanding these standard sizes is useful even when creating custom packaging. It provides a frame of reference for scale. He might design a custom product box that needs to fit inside a standard shipping box like the 3 cube box. Knowing these industry standards helps ensure his creative designs are also practical for the real world of shipping and logistics. It bridges the gap between the design studio and the warehouse floor.

Conclusion

In short, understanding the differences between rigid, folding, and corrugated boxes is the key to choosing the perfect packaging that protects your product and represents your brand effectively.