Struggling with packaging that looks dull or gets scuffed easily? This can damage your brand's image before the product is even seen. Aqueous coating offers a brilliant, protective solution.

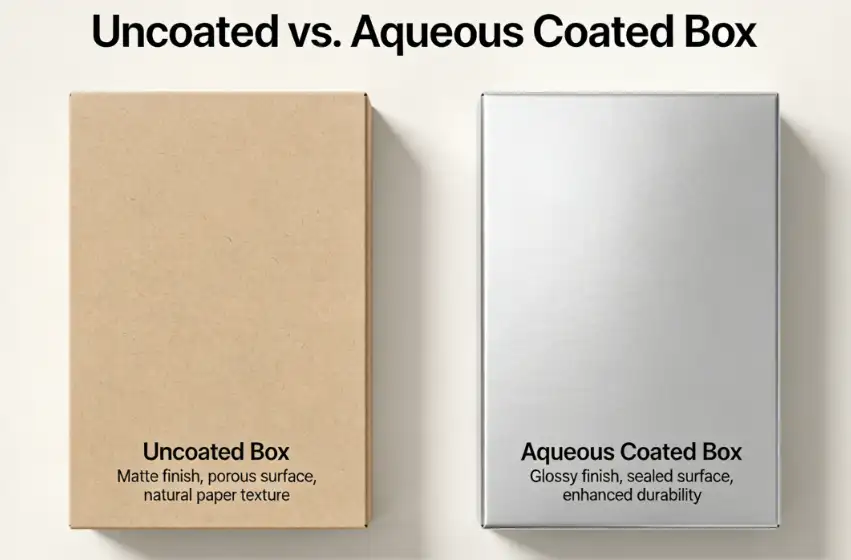

Aqueous (AQ) coating is a water-based, eco-friendly sealant applied during printing to protect and enhance your packaging. It offers finishes like gloss, matte, or satin, providing durability against scuffs and fingerprints while being cost-effective and quick-drying, making your products shine on the shelf.

You see the results of this coating every day, on everything from cereal boxes to luxury gift sets, but what makes this finish so special? Over my 16 years in this industry, I've seen it transform good designs into great ones that create unforgettable unboxing experiences. It’s one of the most reliable tools in our arsenal. Let's dive deeper into what this coating is and how it actually works to protect and elevate your brand's packaging.

What Exactly Is Aqueous Coating And How Does It Work?

Confused about how a simple coating is applied? The process can seem complex, risking production delays or imperfections. It’s a fast, inline process that protects ink instantly.

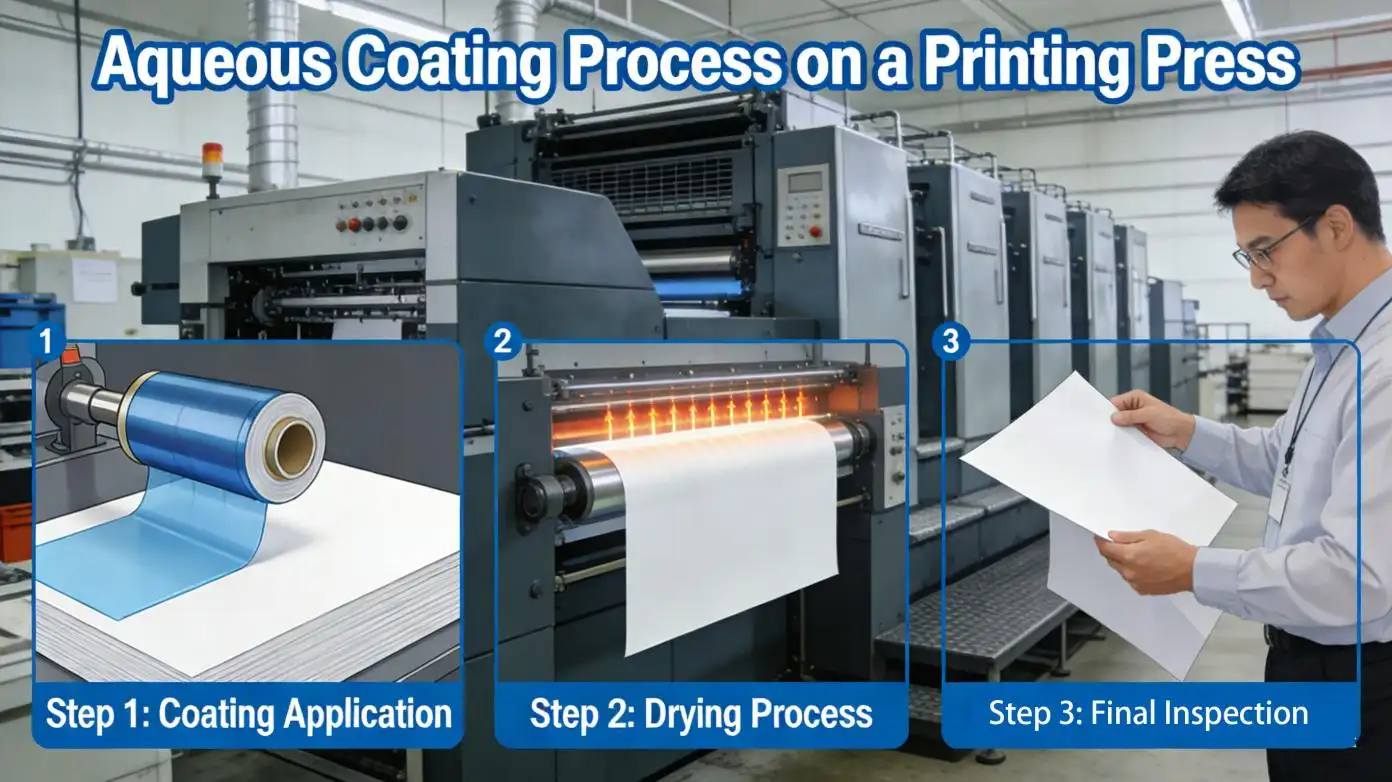

AQ coating is applied by a coating tower on the printing press, right after the ink. The water-based liquid covers the entire sheet, which is then dried by heated air. This immediate sealing process protects the ink and prepares the sheet for finishing without delay.

When I first started in the packaging world, I was amazed by the speed of modern printing presses. But the real "aha!" moment came when I understood the inline coating process. The press applies ink, and a split second later, a dedicated unit applies the aqueous coating over the entire sheet. This is what we call a "flood" coating. The sheet then passes through a series of heaters and fans, and it comes out the other side completely dry and sealed.

This speed is a game-changer. It means the printed sheets can be moved immediately to the next stage—cutting, folding, or gluing—without the risk of the ink smearing or scuffing. It seals the ink away from the air and from contact with machinery. There's no need to wait hours or days for the ink to air dry, which was a major bottleneck with older methods. However, a key thing for designers to remember is that AQ coating is a flood process. It covers everything. This means you can't do "spot" coating like you can with UV. We also have to be careful with paper thickness; lighter paper can sometimes curl under the heat, so we always recommend a suitable paper weight to ensure the final product is perfectly flat and beautiful.

What Are the Different Types of Aqueous Coatings You Can Use?

Choosing the wrong finish can completely misrepresent your brand’s identity. A luxury product with a cheap-looking sheen fails instantly. Each AQ finish serves a different brand identity and purpose.

You can choose from several finishes. Gloss offers a shiny, vibrant look. Matte provides a sophisticated, non-reflective surface. Satin is a balanced middle-ground, while "soft-touch" creates a unique, velvety texture. The right choice depends entirely on the feeling you want to evoke.

Selecting a finish is one of the most creative parts of the process for me. It’s where a designer's vision truly comes to life. I once worked with a chocolatier who wanted their packaging to feel as rich and decadent as the chocolate inside. We tested a standard gloss, but it didn't feel special enough. Then we tried a soft-touch matte coating. The moment the client held it, they knew it was the one. The velvety, tactile sensation created an immediate sense of premium quality. That's the power of the right finish. To help you choose, here is a simple guide:

| Finish | Best For | Texture/Look |

|---|---|---|

| Gloss | Grabbing attention, vibrant colors | Shiny, smooth, reflective |

| Matte | Understated luxury, high readability | Flat, non-reflective, smooth |

| Satin | Elegant feel, excellent durability | Low-level sheen, between gloss & matte |

| Soft-Touch | Premium unboxing, tactile products | Velvety, rubbery, luxurious feel |

Beyond these, there are even specialty options like pencil-receptive coatings for workbooks or dry-erase coatings for interactive packaging. The versatility allows us to create packaging that is not only beautiful but also functional. It's a key reason why aqueous coating is a cornerstone of modern eco-friendly packaging solutions.

Why Choose Aqueous Coating Over Other Finishes Like UV or Varnish?

Facing constant pressure on budgets and timelines? Other coatings can be slow to dry, more expensive, or less friendly to the planet. Aqueous coating offers a balanced, efficient, and eco-friendly alternative.

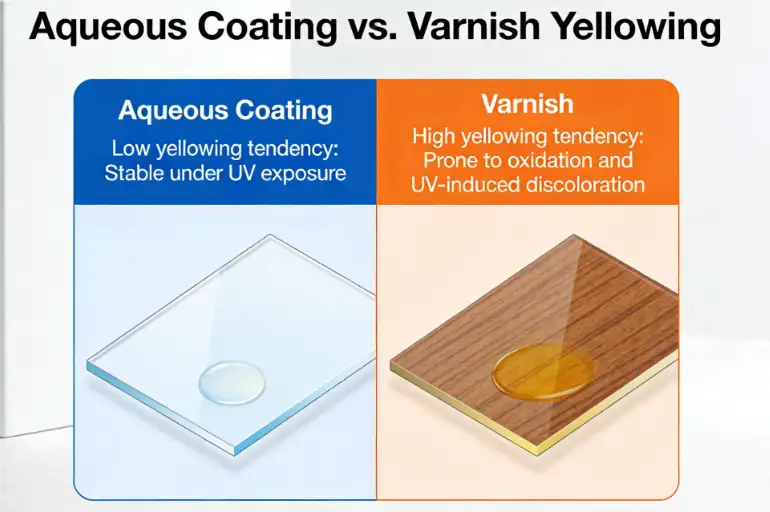

AQ coating is more eco-friendly and often more cost-effective than UV coatings or varnishes. It dries faster, allowing for quicker turnarounds, and is less prone to yellowing over time than varnish. This makes it a superior choice for projects that demand efficiency, sustainability, and long-lasting quality.

Deciding on a coating often comes down to a balance of four things: cost, speed, appearance, and environmental impact. I've guided hundreds of clients through this choice. A few years ago, a large cosmetics company came to us for a big product launch. They were using a traditional oil-based varnish, and the slow drying time was creating a major bottleneck in their production. They were at risk of missing their launch date. We suggested a switch to a satin aqueous coating for their custom paper boxes. The change was revolutionary for them. Not only did the satin finish provide better scuff resistance for shipping, but cutting the drying time completely eliminated their production delays. Plus, the fact that AQ is water-based and easier to recycle was a huge win for their sustainability goals. To make the choice clearer, here’s a direct comparison:

| Feature | Aqueous (AQ) | Varnish (Oil-based) | UV Coating |

|---|---|---|---|

| Cost | Low to Medium | Low | Medium to High |

| Eco-Friendly | High (Water-based, recyclable) | Low (VOCs, harder to recycle) | Medium (Energy-intensive cure) |

| Turnaround | Fast (Instant inline drying) | Slow (Needs hours to air dry) | Fast (Instant UV cure) |

| Durability | Good (scuff-resistant) | Moderate | Very High (chemical resistant) |

| Yellowing | No | Yes, over time | No |

| Spot Coating | No (Flood only) | Yes | Yes (Great for spot effects) |

For most projects, especially high-volume luxury packaging solutions, aqueous coating hits the sweet spot. It provides the protection and premium feel you need without the environmental drawbacks or slow speed of varnish, and it's more affordable than UV coating.

How Can You Best Use Aqueous Coating in Your Packaging Designs?

Worried that your final printed product won't quite match your digital design? Issues like color shifts or problems with glue adhesion can ruin a project. Proper planning is the key to mastering aqueous coating.

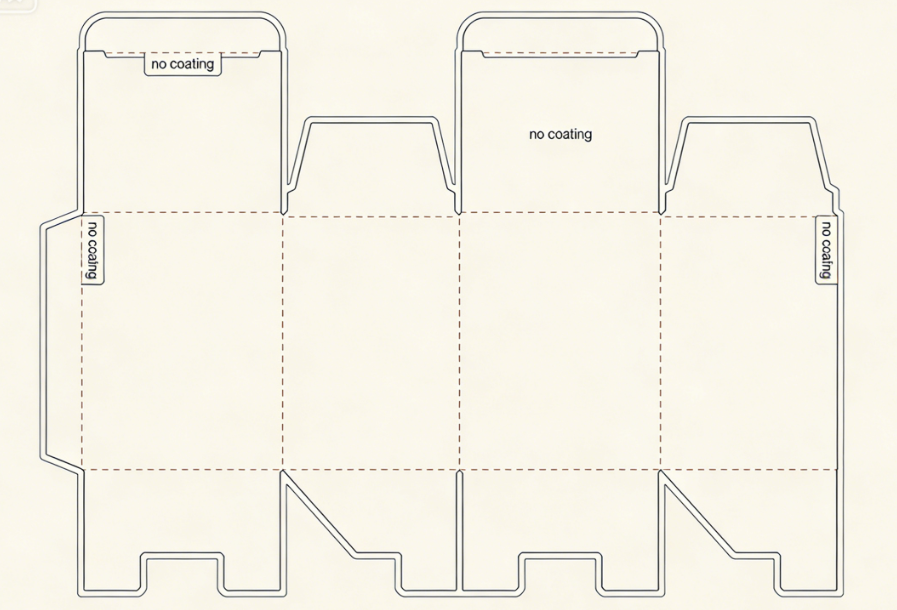

To use AQ coating effectively, always account for slight color shifts by requesting a coated proof from your printer. Ensure your design leaves uncoated areas for gluing, as AQ can resist adhesives. And most importantly, choose the finish that aligns perfectly with your brand's message.

I can't stress this enough: communication with your packaging partner is everything. As a designer, the more you know about the production process, the better your final product will be. I learned this lesson the hard way early in my career. We produced 10,000 beautiful boxes with a gorgeous gloss coating. The problem? The designer hadn't accounted for the glue tabs. The gloss coating repelled the adhesive, and the boxes simply wouldn't stay together. It was a costly mistake. Now, it's a core part of our process.

Designing for Adhesion

On your design file, or dieline, you must create "knockouts" for all glue flaps and panels. This simply means marking these areas to have no coating applied. Your printer will then ensure these specific areas are left uncoated, allowing the glue to form a strong, permanent bond.

Managing Color Expectations

Any coating, whether it's AQ, UV, or laminate, will slightly alter the appearance of your printed colors. A gloss coating will make colors appear richer and deeper, while a matte coating can soften them. Always, always ask your printer for a coated press proof. This allows you to see exactly how your colors will look with the chosen finish and make any necessary adjustments before the full production run.

Matching Finish to Function

Think about the customer's entire journey. Is it a heavy product that will be shipped a long distance? A satin AQ coating offers great scuff resistance. Is it a high-end item where the unboxing is part of the experience? A soft-touch coating will provide that "wow" factor. If you're unsure, talk to us. Our packaging design services team can provide samples and guide you to the perfect finish for your project. Don't hesitate to contact us; we're here to help.

Conclusion

In short, aqueous coating is a versatile, affordable, and green choice. It protects your packaging from scuffs and scratches and makes your brand look its very best on the shelf.