Tired of your beautiful packaging getting scuffed and marked during shipping? Need a protective finish that’s fast, affordable, and eco-friendly? Aqueous coating is the solution you've been looking for.

Aqueous coating (AQ) is a clear, water-based finish applied to printed paper and paperboard. It provides excellent scuff and rub resistance, dries quickly on the press, and is more environmentally friendly than other coatings. It’s a cost-effective way to protect and enhance your packaging's appearance.

For a product designer like Peter, balancing aesthetics, durability, and budget is a daily challenge. You want the final product to look amazing, but it also has to withstand the journey to the customer. After over 16 years in this industry, I’ve seen countless projects succeed or fail based on the finishing touches. A great finish isn't just a luxury; it's a core part of the packaging's function. Let's dive deeper into why aqueous coating has become a go-to choice for so many of our clients.

How Is Aqueous Coating Actually Applied to Packaging?

Worried that adding a coating will slow down your production timeline? The application process is surprisingly efficient and integrated, making it a favorite for projects with tight deadlines.

The magic of aqueous coating is that it's applied "inline" on the printing press. This means it happens in the same run as the printing itself. A special coating unit at the end of the press applies the liquid finish over the wet ink, right before it goes into the dryer.

In my experience, the inline process is a huge advantage. It seals the ink underneath, which allows the printed sheets to be handled and stacked almost immediately without smudging or marking. This dramatically speeds up the overall production time compared to finishes that require a separate, offline process. For designers who need to get their custom packaging solutions to market quickly, this efficiency is a major win. It removes a potential bottleneck and gets the finished product ready for die-cutting and folding much faster.

The Step-by-Step Application Process

Understanding the mechanics helps appreciate the benefits. Here’s a simplified breakdown of what happens on the press:

- Printing: Your design is printed onto the paper or paperboard sheets using standard CMYK or Pantone inks.

- Coating Application: As the sheet moves through the press, it enters a dedicated coating tower. A roller applies a thin, even layer of the liquid aqueous coating across the entire surface.

- Drying: The coated sheet immediately passes through a heated air-drying unit. The water in the coating evaporates, leaving a hard, protective film that is dry to the touch.

- Stacking: The finished, dry sheets are neatly stacked, ready for the next stage of production like cutting and gluing.

| Feature | Inline Application (Aqueous) | Offline Application (e.g., some UV/Laminates) |

|---|---|---|

| Speed | Very fast; part of the printing run. | Slower; requires a separate machine and process. |

| Cost | More cost-effective. | Higher due to extra setup and labor. |

| Handling | Sheets are dry and ready immediately. | Requires drying time or transfer between machines. |

| Best For | High-volume, time-sensitive projects. | Specialty finishes or smaller, complex jobs. |

What Are the Main Types of Aqueous Coatings Available?

Confused about which finish to choose? From shiny and bold to subtle and sophisticated, there's an aqueous coating type that can perfectly match your brand's aesthetic and functional needs.

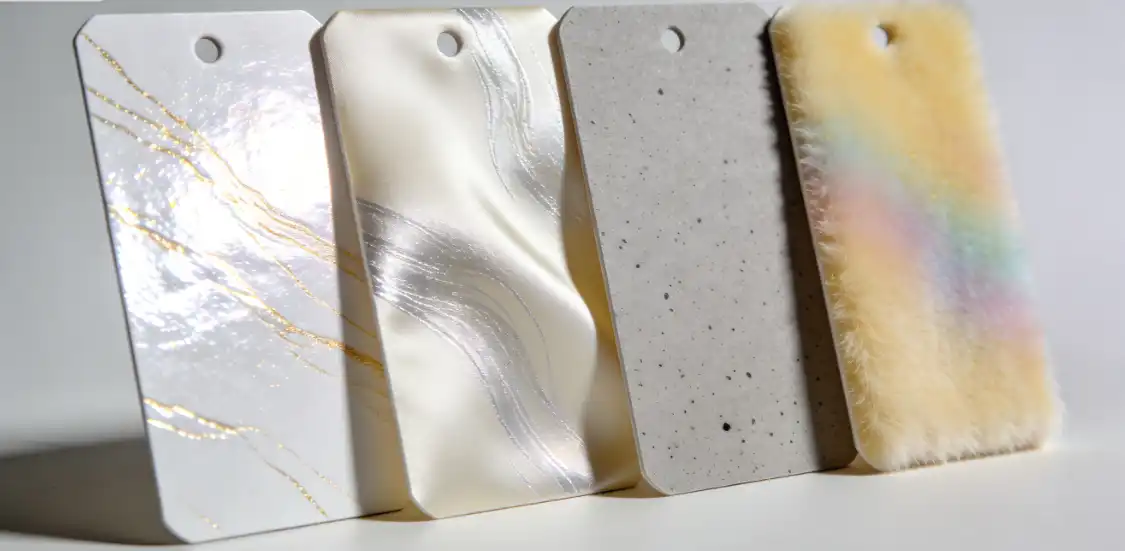

The most common types are Gloss, Satin, and Matte. Each offers a different look and feel, allowing you to fine-tune your packaging's shelf presence. Choosing the right one is key to making your design pop and communicating the right brand message to your customers.

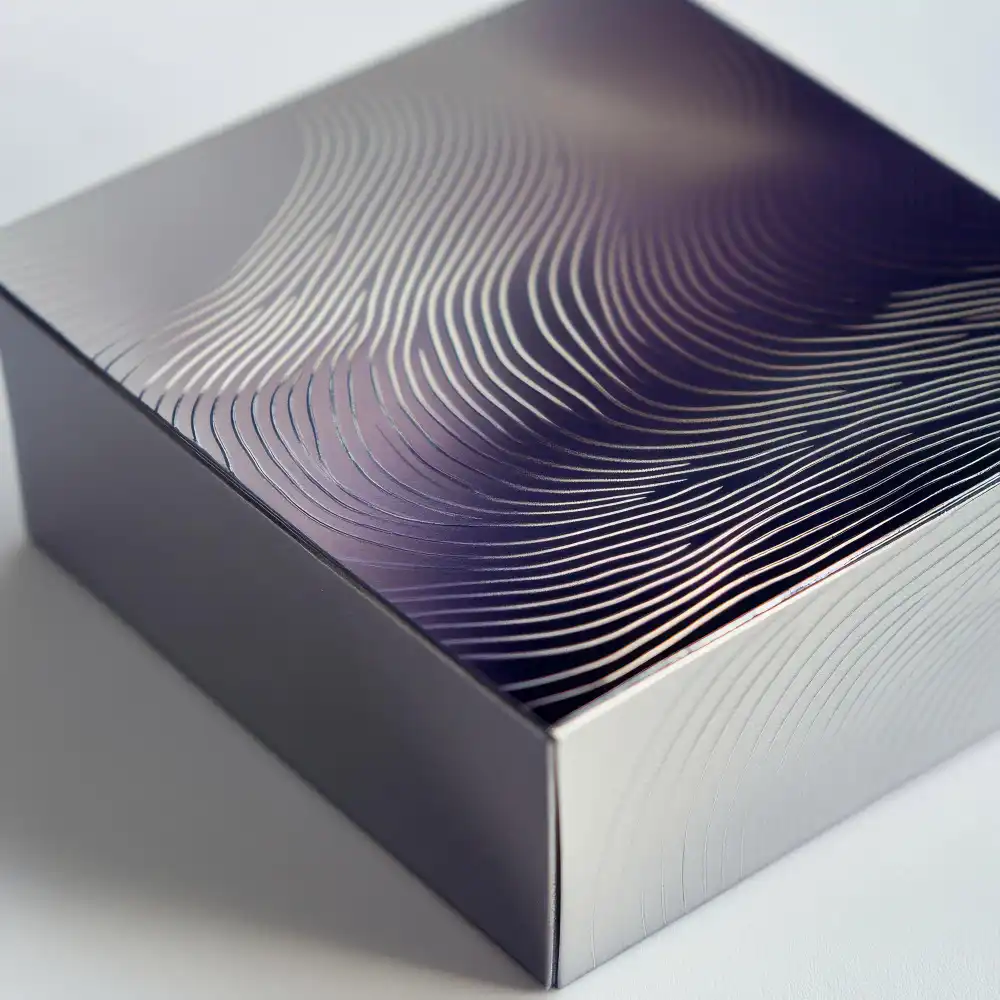

When I work with designers, the choice of finish is one of our most important conversations. It's not just about looks; it's about the brand's identity. A high-gloss finish can scream excitement and value, perfect for retail electronics or cosmetics. A matte finish, on the other hand, suggests organic quality, subtlety, and premium feel, which is ideal for artisanal food products or sustainable brands. We’ve even used satin for corporate kits where the client wanted a professional look that wasn't too flashy. There's also a specialty option called Soft-Touch, which feels like velvet and adds a luxurious tactile experience. For any high-quality paper box, the finish is the first thing a customer sees and feels.

Choosing the Right Finish for Your Brand

Your choice of coating directly impacts customer perception. Think about what you want your packaging to say about your product.

- Gloss: Creates a shiny, reflective surface that makes colors appear more vibrant and saturated. It’s excellent for catching the eye on a crowded shelf.

- Satin: A happy medium. It has a slight sheen but is less reflective than gloss. It offers good scuff protection and a refined, low-glare appearance.

- Matte: Provides a non-reflective, smooth, and elegant finish. It can make a product feel more premium and sophisticated, but it shows fingerprints more easily than gloss.

- Soft-Touch: This is a type of matte coating that adds a velvety, rubbery texture. It creates a memorable unboxing experience and signals high-end luxury.

| Finish Type | Visual Appearance | Feel | Best Use Case |

|---|---|---|---|

| Gloss | High-shine, vibrant | Smooth, slick | Retail, food, cosmetics |

| Satin | Low-sheen, elegant | Smooth | Corporate, pharmaceuticals, publications |

| Matte | No shine, flat | Smooth, natural | Luxury goods, organic products |

| Soft-Touch | No shine, flat | Velvety, soft | High-end electronics, premium gifts |

Is Aqueous Coating a Better Choice Than UV Coating or Varnish?

Trying to decide between the different coating options? While UV and varnish have their place, aqueous coating often strikes the perfect balance between performance, cost, and environmental responsibility for many projects.

Aqueous coating is frequently compared to press varnish and UV coating. Varnish is oil-based and less durable. UV coating is cured with ultraviolet light, offering maximum protection and gloss but at a higher cost and with a larger environmental footprint. Aqueous coating sits comfortably in the middle.

This is a question I get almost daily. The truth is, "better" depends on the project's specific goals. If a client needs the highest possible gloss and indestructible protection for a luxury rigid box, I might recommend UV coating. However, for the majority of folding cartons and mailer boxes, aqueous coating is my top recommendation. It provides more than enough protection for shipping and handling, looks fantastic, and keeps costs down. It’s also a big plus for clients who want to promote their sustainable options, as it's water-based and doesn't hinder recyclability like some other finishes. This balance is why AQ has become the workhorse of the packaging industry.

A Head-to-Head Comparison

Let's break down the key differences to help you make an informed decision for your next project.

- Protection: UV offers the best protection against scratches and chemicals. Aqueous is a close second, offering excellent scuff resistance. Varnish offers the least protection.

- Cost: Varnish is the cheapest. Aqueous is slightly more expensive but offers far better performance. UV is the most expensive option due to the special equipment and energy required.

- Environmental Impact: Aqueous is the winner here. It's water-based, has low VOCs (Volatile Organic Compounds), and is easily recyclable. UV is less eco-friendly, and oil-based varnishes have a higher VOC content.

| Attribute | Aqueous Coating | UV Coating | Press Varnish |

|---|---|---|---|

| Durability | High (Excellent scuff resistance) | Highest (Very hard, chemical resistant) | Low (Basic protection) |

| Appearance | Gloss, Satin, Matte, Soft-Touch | Highest gloss available; also in matte | Gloss, Satin, Matte |

| Cost | $$ | $$$ | $ |

| Eco-Friendly | High (Water-based, low VOCs) | Medium (Energy intensive curing) | Low (Oil-based, higher VOCs) |

| Yellowing | Non-yellowing | Non-yellowing | Can yellow over time |

Are There Any Downsides to Using Aqueous Coating?

Is aqueous coating perfect for every single project? While it's incredibly versatile, there are a few limitations to be aware of. Knowing these helps you plan your design effectively and avoid potential issues.

No single solution is perfect. The main challenges with aqueous coating are minor color shifts, potential issues with gluing or foil stamping, and incompatibility with certain metallic inks. However, an experienced packaging partner can easily navigate these challenges.

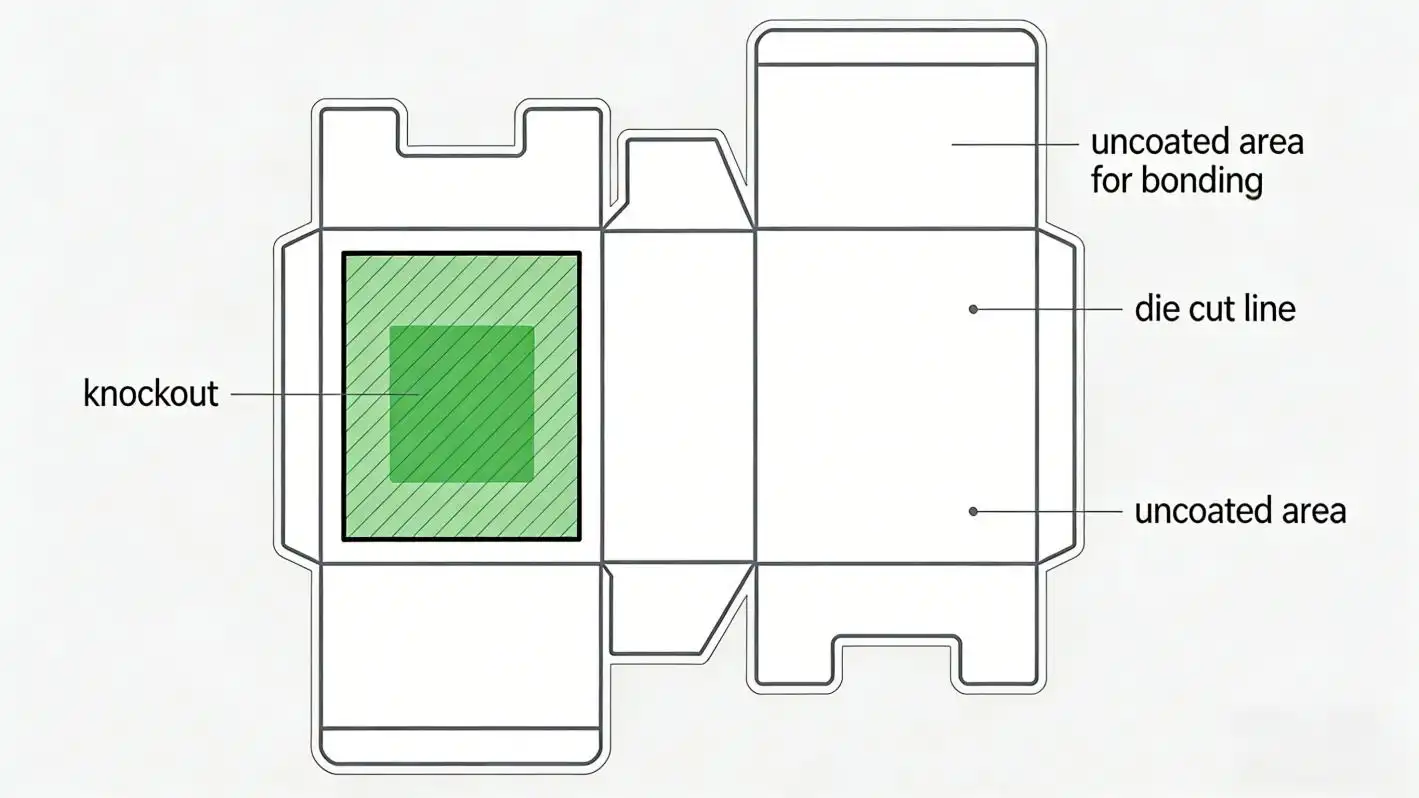

I've learned over the years that foresight prevents problems. For example, some deep blue and purple inks can have a slight color shift when a gloss aqueous coating is applied. To prevent this, we always recommend a press proof with the coating included so the client can approve the final color. Another common issue is gluing. The slick surface of the coating can resist adhesives. We solve this by creating a "knockout"—a small, uncoated area on the glue flaps. This allows the glue to bond paper-to-paper, ensuring a strong, reliable seal. These are the kinds of details that enhance their brand value by ensuring the final package is flawless.

Potential Challenges and How to Solve Them

Being aware of limitations is part of being a great designer. Here are the main things to watch for and how we manage them at Giftspack.

- Challenge: Color Shift

- Some inks, especially reflex blue and purple, can appear to change shade slightly after coating.

- Solution: Always request a production-level proof (a "drawdown") with the exact ink and coating combination for approval before the main run.

- Challenge: Adhesion Issues

- The smooth, sealed surface of an aqueous coating can't be easily written on with a pen and can resist some glues and foil stamping adhesives.

- Solution: We design "knockouts" or uncoated windows in the areas where you need to glue, stamp, or write. This is a standard practice that a good supplier will handle automatically.

- Challenge: Metallic Inks

- Aqueous coating can sometimes cause metallic inks to lose their brilliance and appear dull.

- Solution: For designs with prominent metallic elements, we often recommend spot varnishing just the non-metallic areas, leaving the metallic ink exposed for maximum shine.

By working with an experienced team, these potential downsides are easily managed, ensuring your vision is executed perfectly.

Conclusion

Aqueous coating is a versatile, protective, and cost-effective finish. It's an excellent choice for most packaging projects, balancing durability with speed and sustainability, making it a true industry standard.