Are you curious about the standard cigarette pack count? This number isn't random; it deeply affects packaging design, manufacturing costs, and even regulatory compliance. Let's break it down together.

The standard cigarette pack almost universally contains 20 cigarettes. This number is a carefully balanced result of historical manufacturing efficiency, tax laws, and consumer habits. For a packaging expert, this count is the foundational blueprint that dictates a box's dimensions, material strength, and branding space.

The simple answer is 20, but the story behind that number is far more interesting. As someone who has spent over a decade and a half in the packaging industry, I've learned that every dimension and count has a purpose. This number influences everything from the paperboard we select to the printing machines we use. To truly understand packaging, we need to look beyond the product and into the reasons behind its container. This journey starts with understanding the history and logic behind the 20-cigarette standard.

Why Did 20 Cigarettes Become the Standard Size for a Pack?

Ever wonder why packs aren't sold in 15s or 25s? This standard wasn't an accident. It was shaped by production machinery and early tax laws.

The 20-cigarette standard originated from early 20th-century automated packing machinery. These machines were designed to efficiently handle two rows of 10 cigarettes. This configuration proved optimal for production speed and consistency, and tax laws were later structured around this convenient 20-unit count, cementing it as the industry norm.

When I first started in packaging, one of my mentors shared how legacy equipment still influences modern design. The 20-pack is a perfect example. Early packing machines, like the Bonsack machine, revolutionized the industry. Their mechanics were optimized for specific counts, and 20 was the magic number for balancing speed, reliability, and the final pack's pocket-friendly size.

The Driving Forces Behind the 20-Pack Standard

This standard wasn't just about machines; it was a combination of factors that created the perfect storm for the 20-pack to dominate the market.

| Factor | Description | Impact on Packaging |

|---|---|---|

| Manufacturing Efficiency | Early automated machinery was engineered to group cigarettes in two rows of 10. This was the most mechanically simple and fast method. | This defined the classic "flip-top box" or "soft pack" dimensions, which are still used today. |

| Taxation and Regulation | Governments found it easier to levy taxes on a standardized unit. Taxes were often applied per pack of 20, discouraging smaller, cheaper packs. | Packaging must prominently display tax stamps, and the design must accommodate their specific size and placement. |

| Consumer Convenience | A pack of 20 was considered a sufficient supply for one or two days for an average smoker. The box size was perfect for pockets and purses. | The ergonomic and portable nature of the pack became a key design feature. Structural integrity was crucial. |

| Cost Management | For manufacturers, standardizing to 20 units allowed for predictable material purchasing, production runs, and pricing strategies across the board. | It enabled us to create custom rigid boxes and other packaging solutions at scale, knowing the exact internal volume required. |

Are There Different Cigarette Pack Sizes Around the World?

Thinking a 20-pack is the only option? Many countries have different rules. These variations create unique challenges and opportunities for packaging designers everywhere.

Yes, pack sizes vary globally due to different tax laws and public health regulations. While 20 is the most common, some regions allow 10, 25, or even 30 cigarettes per pack. Many countries, however, have banned smaller packs to discourage youth smoking by making the entry price higher.

In my work at Giftspack, we often handle projects for international clients. This means navigating a maze of different regulations. A design that is perfect for the Canadian market (where 25-packs are common) would be illegal in the European Union, which has mandated a minimum of 20 cigarettes per pack. This is where a deep understanding of global standards becomes critical. It's not just about design; it's about compliance. A small mistake in pack count can lead to an entire shipment being rejected at the border, a costly error that we help our clients avoid.

A Global Snapshot of Pack Size Regulations

The rules are constantly changing, but here is a look at some common variations and the logic behind them. For designers like Peter, keeping up with these is part of the job.

| Region/Country | Common Pack Sizes | Regulatory Reason | Packaging Implication |

|---|---|---|---|

| European Union | Minimum of 20 | Public Health: To make cigarettes less affordable and accessible, especially to young people. Bans on 10-packs are common. | Designs must be standardized for the 20-count minimum. Large health warnings (65% of the surface) are mandatory. |

| Australia | 20, 25, 30, 40, 50 | Public Health & Taxation: Plain packaging laws remove all branding. Larger packs are available, but high taxes make them very expensive. | The ultimate challenge: create a functional box with no branding. Focus is purely on structure and compliance with drab green color requirements. |

| Canada | 20, 25 | Market & Consumer Preference: King-size cigarettes are often sold in packs of 25. | Requires designers to create two distinct structural designs. The "slide-and-shell" format is unique to Canada's plain packaging rules. |

| United States | 20 (standard) | Historical & Market Precedent: The 20-pack has been the unchallenged standard for decades. | Consistency in design, but fierce competition in branding and finishing, like embossing and foils, to stand out on the shelf. |

How Does Pack Count Affect Custom Cigarette Box Design?

Does changing from 20 to 25 cigarettes really matter? Absolutely. This single change impacts material choice, structural design, and the entire printing process.

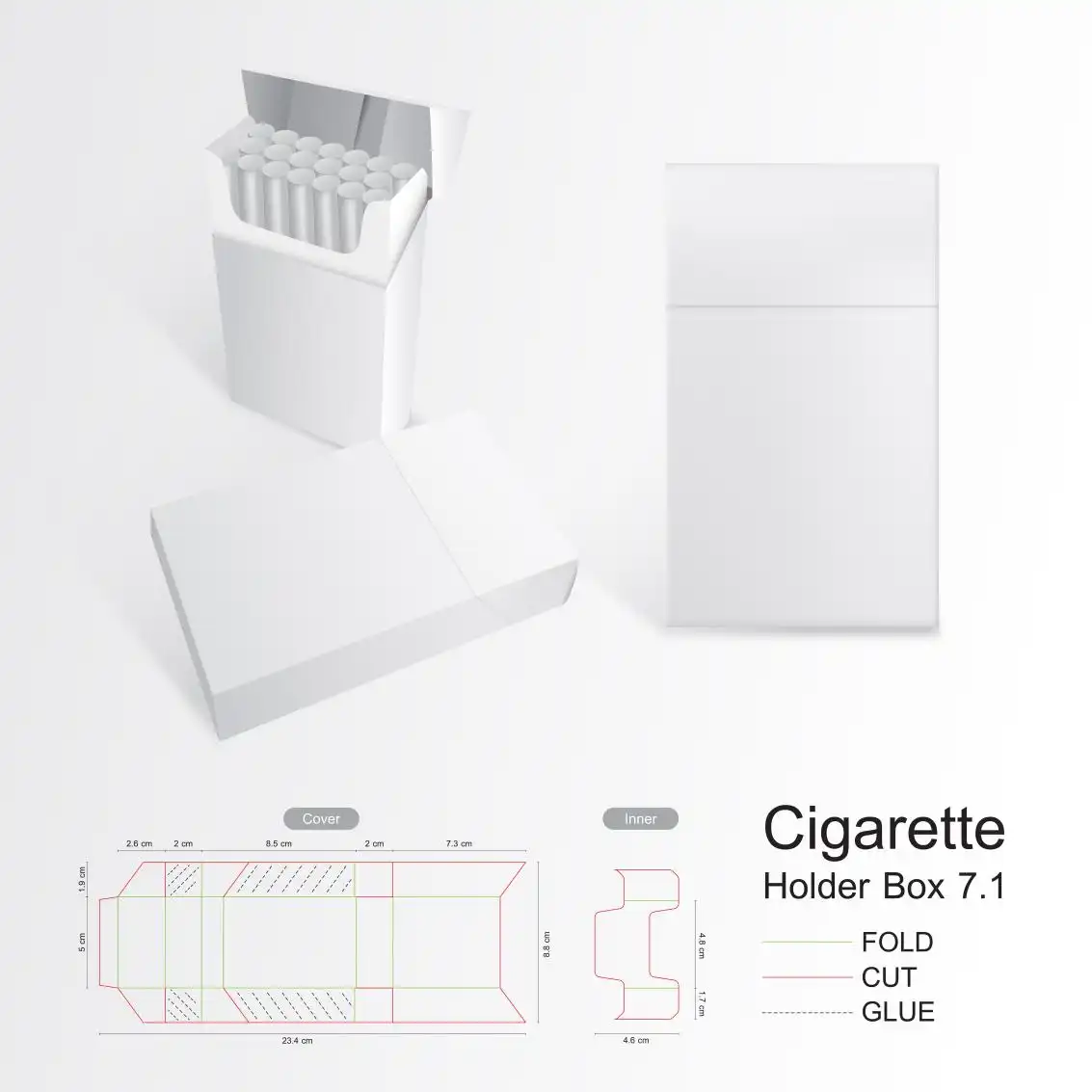

The cigarette count directly dictates the box's dimensions, structural design, and material requirements. A higher count requires a larger, often stronger box, affecting material costs and graphic layout. It challenges designers to maintain brand identity and structural integrity while adapting to new proportions and regulatory constraints.

This is where my team and I spend a lot of our time. A client might request a unique 22-pack for a special edition. My job is to translate that request into a physical, manufacturable product. We have to consider how the new dimensions will affect the performance of our custom paper boxes. Will the flip-top lid still feel snappy? Will the box walls resist crushing in a pocket? These are the practical problems we solve every day. It's a balance of art and engineering.

Key Design Considerations for Different Pack Counts

When a designer like Peter gets a new project, the pack count is the first variable he needs to lock down. Here’s a breakdown of what that number influences.

-

Structural Integrity:

- 20-Pack: The classic design is highly optimized. The internal frame (inner frame) and flip-top lid provide excellent rigidity for its size.

- 25+ Pack: A wider or taller box is more susceptible to bending and crushing. We might need to use a thicker paperboard (higher GSM) or introduce reinforcing elements inside the pack. The design must ensure the cigarettes at the ends are just as protected as those in the middle.

-

Material Consumption:

- It’s not a linear increase. A larger pack requires a larger single sheet of paperboard (a larger die-cut), which can lead to more material waste depending on how it fits on a master production sheet. Optimizing the layout to minimize waste is a crucial part of our custom packaging solutions.

-

Branding and Graphics:

- A larger surface area seems like a benefit, but it comes with challenges. Health warnings are often a percentage of the surface, so on a larger pack, the warning is also larger, potentially overshadowing the brand. Designers must skillfully rearrange brand elements to fit the new proportions while maintaining brand recognition.

-

Manufacturing and Assembly:

- Our automated machinery is tuned for standard sizes. Introducing a new size requires recalibrating or even re-tooling the machines. This involves adjusting folding plates, gluing nozzles, and packing arms. It's a significant undertaking that adds to the project cost and timeline.

What Are the Future Trends for Cigarette Packaging?

Thinking cigarette boxes are stuck in the past? The industry is facing huge pressure. Sustainability, smart features, and regulations are forcing designers to innovate like never before.

Future cigarette packaging trends are driven by sustainability and regulation. Expect to see more biodegradable materials, the removal of plastic film wraps, and the integration of "smart" features like QR codes for verification. Plain packaging regulations will continue to expand globally, shifting the focus from branding to structural innovation.

As a packaging manufacturer, staying ahead of these trends is essential for survival. At Giftspack, we are constantly exploring new eco-friendly packaging options, from recycled paperboards to plant-based inks. We're not just waiting for regulations to force our hand; we're actively helping our clients prepare for the future. For example, we've prototyped packs that eliminate the traditional polypropylene overwrap, replacing it with a clever structural seal. This kind of forward-thinking is what keeps us relevant and valuable to our partners.

The Next Wave of Packaging Innovation

The pressure to evolve is creating some exciting new directions for what has been a very traditional packaging format.

| Trend | Description | Impact on Design and Manufacturing |

|---|---|---|

| Sustainability | A major push to eliminate single-use plastics, like the outer film wrap and plastic in filters. There is growing demand for FSC-certified paper and biodegradable materials. | Designers must find structural ways to seal packs and ensure freshness without plastic. Manufacturers like us are sourcing and testing new, greener materials. |

| Plain Packaging | More countries are adopting laws that strip all branding, logos, and colors from packs, standardizing them with a drab color and large health warnings. | The designer's focus shifts entirely from graphic design to structural design. Innovation in opening mechanisms or unique textures (where allowed) becomes the only differentiator. |

| Smart Packaging | Integration of QR codes or NFC chips for track-and-trace systems to combat counterfeiting, provide product information, or link to smoking cessation programs. | Requires careful integration into the graphic layout and printing process. The package becomes a digital gateway, adding a new layer of functionality. |

| Alternative Products | The rise of vaping devices and heated tobacco products requires entirely new packaging formats. These often fall under different regulations and have different needs (e.g., space for chargers, pods). | This is a whole new frontier for custom packaging design. It involves designing for electronics, ensuring child-resistance, and communicating a different product use. |

Conclusion

So, a pack usually has 20 cigarettes, a standard born from history and efficiency. But this number shapes everything from material cost to global compliance, pushing packaging design to constantly evolve.