Struggling to understand the sudden surge in corrugated box demand? This trend directly impacts your costs and material access. I will break down the key drivers behind it for you.

The demand for corrugated boxes is rising mainly because of the global e-commerce boom and a strong push for sustainable packaging. Its versatility and low cost make it the top choice for shipping nearly everything, from fresh food to electronics, solidifying its essential role in today's supply chain.

But knowing why is just the start. To make smart decisions for your packaging designs, you need to understand the details. The factors driving this trend also affect pricing1, material availability2, and what clients will ask for next. Let's dig deeper into the specifics of this demand, the price pressures it creates, and what the future holds for this essential material.

What is the demand for corrugated boxes?

You see them everywhere, but what does the actual market demand look like? It feels huge, but pinning down the numbers and reasons can be tricky. I'll give you a clear snapshot.

The global demand for corrugated boxes is massive, measured in billions of square meters each year. This is driven by online retail, food and beverage shipping3, and general manufacturing. This strong, consistent demand shows its vital role in modern logistics and supply chains everywhere.

The E-commerce Engine

The biggest driver, without a doubt, is e-commerce. Every time someone clicks "buy now," a box is needed to ship that product. Before the internet, products moved on pallets to a retail store. Now, individual items go directly to homes. This shift created an explosive need for smaller, durable shipping boxes. I saw this firsthand in my business. Around ten years ago, most of our orders were for large, uniform boxes for businesses. Today, a huge part of our work is creating custom-sized mailer boxes4 for online sellers who need a thousand different sizes for their products. This one-to-one shipping model is the engine powering a huge part of the corrugated market today.

The Sustainability Shift

Another huge factor is the move away from plastic. Consumers and governments are demanding more environmentally friendly options. Corrugated board is a star player here. It is typically made from a high percentage of recycled materials5 and is easily recyclable again after use. As a designer, you know that clients are increasingly asking for "plastic-free" packaging. I've had countless conversations with brands wanting to replace plastic trays, foam inserts, and poly mailers. The best solution, in most cases, is a clever corrugated design. This green reputation isn't just a trend; it's a fundamental shift in how we view packaging responsibility6.

Unmatched Versatility

Finally, demand is high simply because the material is so incredibly versatile. It's not just a brown shipping3 box. We use it to create strong, protective packaging with complex inserts for fragile electronics. We make high-impact retail-ready packaging that sits on store shelves. We can print beautiful, full-color graphics on it for a premium subscription box. Its ability to be strong, lightweight, printable, and endlessly customizable makes it the go-to solution for thousands of problems. This flexibility ensures that as products and markets change, corrugated packaging can change with them.

Why are corrugated prices going up?

Is your packaging budget getting squeezed by rising corrugated costs? You have to explain these increases to your clients or your boss. I'll give you the simple reasons behind it.

Prices are going up because of a mix of factors. The cost of raw materials like recycled paper is higher. Energy prices for manufacturing have surged. Transportation is more expensive, and simple supply and demand7 imbalances are pushing costs up across the board.

The Squeeze on Raw Materials and Supply Chains

The core ingredient for most corrugated board is old corrugated containers (OCC), which is just a technical term for used cardboard boxes. With the e-commerce boom, the demand for OCC is higher than ever. This creates more competition for a limited resource, driving up its price. At the same time, global supply chain problems have also affected the cost and availability of virgin kraft paper, which is used for the outer layers of the board for strength and print quality. I remember in 2021, our paper costs jumped nearly 30% in just a few months. It was a tough conversation to have with clients, but it was a reality across the entire industry, not just at Giftspack.

Rising Energy and Transportation Costs

Making corrugated board is an energy-intensive process. The large machines used to pulp paper, press the board, and dry it consume a lot of electricity and natural gas. When global energy prices8 go up, the cost to run these mills goes up, and that cost is passed on. Then, once the boxes are made, they have to be shipped. The rising cost of fuel and a shortage of truck drivers have made freight more expensive than ever. A pallet of boxes that cost $100 to ship a few years ago might cost $200 or more today. This logistics cost is a significant part of the final price you pay.

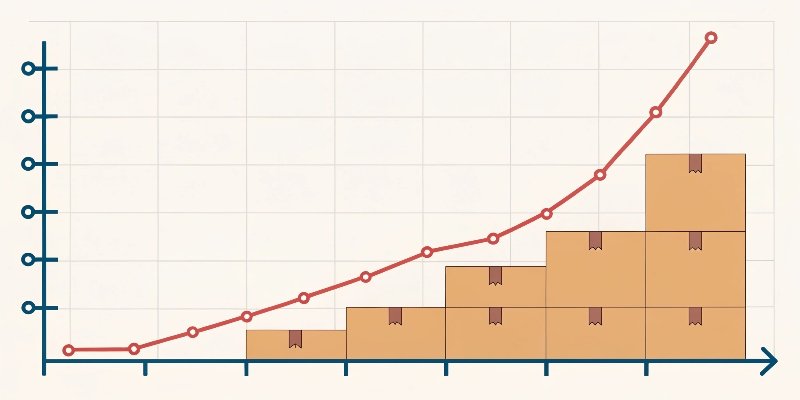

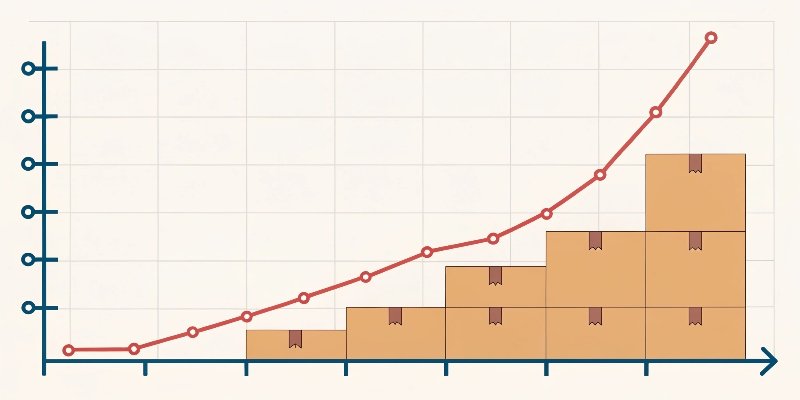

The Simple Economics of It All

Ultimately, it comes down to basic supply and demand7. More businesses need more boxes, but the capacity to produce those boxes hasn't grown as fast. This imbalance gives paper mills and manufacturers more leverage to set prices. Here is a simple breakdown:

| Cost Factor | Why It's Increasing | Impact on Final Box Price |

|---|---|---|

| High Demand | E-commerce and sustainability trends. | Major |

| Raw Material Costs | More competition for recycled paper (OCC). | Major |

| Energy Prices | Higher global costs for gas and electricity. | Moderate |

| Labor Shortages | Fewer workers in manufacturing and trucking. | Minor |

| Transportation | Higher fuel prices and driver shortages. | Moderate |

When you combine all these smaller increases, you get the significant price jump we are seeing in the market today.

Which industry uses most corrugated boxes?

Ever wonder where all these billions of boxes are actually going? Knowing the biggest user helps you understand the broader market trends. Let’s look at who the top consumer is.

The food and beverage industry9 is the largest single user of corrugated boxes by a wide margin. It uses boxes for everything from shipping3 bulk produce to casing canned goods and creating retail-ready displays. Its huge need for safe, cheap, and efficient transport makes corrugated its number one choice.

Food and Beverage: The Undisputed Leader

The need for corrugated in the food and beverage sector is enormous and varied. Think about it. Fresh produce like fruits and vegetables is shipped from farms to distribution centers in sturdy corrugated crates that protect the contents and allow for airflow. Processed foods, from cereal boxes to snack bags, are packed into larger corrugated cases for shipment to grocery stores. Beverage companies use corrugated trays and boxes to transport billions of bottles and cans every year. The key requirements in this industry are strength, hygiene, and cost-effectiveness. Corrugated board delivers on all three, providing a clean, single-use package that can be stacked high in a warehouse without crushing the products inside.

The Fast-Growing E-commerce Sector

While food and beverage is the biggest user, the e-commerce and retail sector is the fastest-growing. This is where a lot of design innovation happens. This sector requires a massive range of box sizes to fit countless different products. It also puts a premium on the "unboxing experience." This has driven demand for high-quality printing, custom inserts, and unique box styles. As a designer, this is likely where you focus much of your energy. I remember working with an electronics client who needed a box to ship a delicate device. We designed a system of complex corrugated inserts that suspended the product, protecting it from shocks during transit. This kind of value-added design is a hallmark of the e-commerce packaging space.

Essential for All Other Industries

Beyond these two giants, corrugated packaging is essential for almost every other industry that makes a physical product. The electronics industry relies on it for protection. The home and personal care sector uses it to ship everything from soap to furniture. Even heavy industrial goods, like automotive parts, are often shipped in specialized, high-strength "triple wall" corrugated boxes. The truth is, almost every product you touch has spent some part of its journey in a corrugated box. It is the invisible, hardworking backbone of the global supply chain, which is why its use is so widespread.

What is the future of corrugated board packaging to 2029?

Thinking ahead is critical for any designer. Is corrugated a safe bet for the future? You need to know where the industry is going to stay ahead of the curve.

The future of corrugated packaging10 to 2029 looks incredibly strong, with steady growth expected. The key trends will be smarter packaging with integrated tech, greater sustainability with lighter materials and new coatings, and advanced digital printing11 for amazing customization.

Smart and Digital Packaging

The biggest change on the horizon is the shift to digital. For decades, printing on a box required expensive printing plates, making small orders or design changes difficult. Now, high-speed digital printing is becoming more common. This is a game-changer. It allows for cost-effective, high-quality printing on small batches of boxes. Brands can create seasonal designs, personalized packaging, or test new looks without a huge investment. Beyond printing, we'll see more "smart" boxes. This could mean a QR code that links to an instruction video or an NFC chip that tracks the package's journey and confirms its authenticity. These technologies turn a simple box into an interactive tool.

The Next Level of Sustainability

Sustainability will go beyond just being recyclable. The focus will shift to doing more with less. This is called "lightweighting12," which means engineering boards that use less paper but maintain their strength. This reduces waste and shipping costs. I'm also seeing exciting developments in eco-friendly coatings. For years, keeping moisture away from a box meant using wax or plastic coatings, which made recycling difficult. New plant-based, biodegradable coatings13 are emerging that provide that same protection while keeping the box 100% repulpable. We are even exploring new fiber sources, like bamboo or agricultural waste, to reduce our reliance on trees.

Automation and Design for Manufacturing

Behind the scenes, the factories that make boxes are becoming more automated. Robotic systems are making production faster, safer, and more consistent. For a designer like you, this is important to know. As machines get faster and more precise, the design files you create must be perfect. There's less room for error. Thinking about how a box will be folded and glued by a machine, not just a person, will become a more important part of the design process. This focus on "design for manufacturing14" will ensure that your creative ideas can actually be produced efficiently at scale, bridging the gap between a great concept and a great final product.

Conclusion

Corrugated demand is rising from e-commerce and sustainability. Though prices are up, the future is bright with innovations in smart, eco-friendly, and digitally printed packaging making it more versatile than ever.

-

Stay informed about pricing trends to better manage your packaging budget. ↩

-

Discover the key factors that impact the availability of materials for packaging. ↩

-

Learn how shipping requirements influence packaging design and material selection. ↩ ↩ ↩

-

Find out how custom-sized mailer boxes can enhance your shipping efficiency and customer satisfaction. ↩

-

Learn about the role of recycled materials in creating sustainable packaging solutions. ↩

-

Understand the significance of packaging responsibility in today's market. ↩

-

Gain insights into how supply and demand dynamics influence packaging costs. ↩ ↩

-

Understanding energy costs can help you anticipate changes in packaging prices. ↩

-

Discover why the food and beverage sector relies heavily on corrugated packaging. ↩

-

Stay ahead of industry trends by exploring the future of corrugated packaging. ↩

-

Learn how digital printing can enhance your packaging design and production efficiency. ↩

-

Explore how lightweighting can reduce costs and improve sustainability in packaging. ↩

-

Understand the importance of biodegradable coatings for sustainable packaging solutions. ↩

-

Learn about the importance of design for manufacturing to ensure efficient production. ↩