Worried your premium products are vulnerable inside their packaging? Standard boxes often feel basic and fail to create a memorable experience, hurting your brand's luxury appeal.

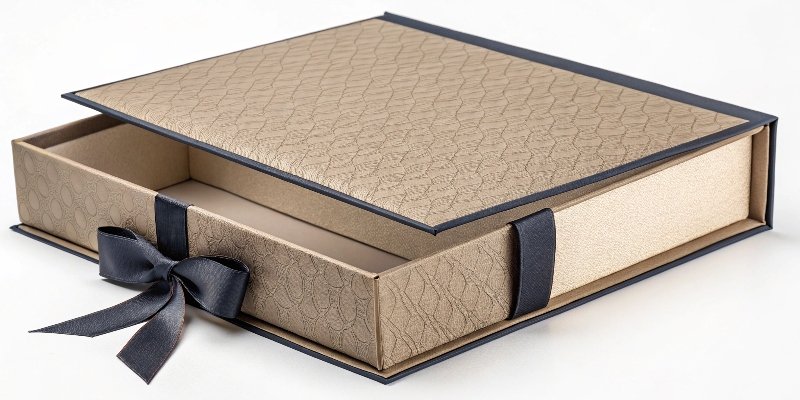

The best way to enhance book-style rigid boxes is by adding features like secure magnetic closures, elegant ribbon pulls for easy opening, and custom foam or paper inserts. For top-tier security, you can integrate NFC tags or hidden QR codes to offer product authentication and interaction.

These features are more than just simple add-ons. They work together to transform a simple container into a secure and interactive part of the customer experience. But with so many options, how do you know which ones are right for your product and your budget? It’s about finding the perfect balance between style, function, and cost. In my years of experience, I've helped countless brands navigate these choices. Let's break down the details so you can make the best decision.

What are the benefits of custom two piece rigid boxes?

Does your standard box feel disconnected from your brand's unique story? Generic packaging can make even the most premium product seem ordinary and easily forgotten by customers.

The main benefits of custom rigid boxes are superior brand presentation through unique printing and finishes, a perfect fit for better product protection, and a memorable unboxing experience. This customization directly elevates your product's perceived value and strengthens brand loyalty from the first touch.

When a customer holds a box designed specifically for the product inside, it sends a powerful message. It says you care about every detail. I've seen brands completely transform their market position just by investing in custom packaging. It's not just a box; it's the first chapter of your product's story. Let's explore how these benefits come to life.

Enhanced Brand Storytelling

Customization allows your packaging to become a canvas for your brand. You aren't limited to a simple logo. You can use specific colors, textures, and finishes that align with your brand's identity. For example, a sustainable brand might choose a raw, uncoated paper finish, while a luxury tech brand might opt for a sleek, soft-touch laminate with a metallic foil stamp. This tactile and visual experience communicates your brand's values before the customer even sees the product.

Superior Product Protection

One of the most practical benefits is creating a box that fits your product perfectly. "One-size-fits-all" is a recipe for damaged goods. With custom inserts made from foam, molded pulp, or die-cut paperboard, you can secure your product, preventing it from shifting during transit. This not only reduces return rates but also shows your commitment to quality.

Elevated Customer Experience

The unboxing experience is now a critical marketing touchpoint. A custom rigid box can be designed with a satisfying magnetic closure, a silk ribbon pull, or a layered reveal. These small details make the act of opening the package feel special and luxurious, creating a lasting positive impression.

| Customization Feature | Impact on Branding | Impact on Protection |

|---|---|---|

| Foil Stamping | High (Adds luxury feel) | Low |

| Embossing/Debossing | High (Adds texture and sophistication) | Low |

| Custom Inserts (Foam/Pulp) | Medium (Shows attention to detail) | High (Secures product perfectly) |

| Magnetic Closure | High (Creates premium feel) | Medium (Keeps box securely closed) |

What are the benefits of rigid boxes?

Is your current packaging easily crushed during shipping or on a busy retail shelf? Flimsy boxes can lead to damaged products, costly returns, and a tarnished brand reputation.

Rigid boxes offer exceptional structural strength, which provides superior protection for fragile or high-value items. Their premium feel boosts brand perception, and they are often kept and reused by consumers, adding long-term brand exposure and value well beyond the initial sale.

The core advantage of a rigid box is right in its name: it's rigid. Unlike a folding carton that is shipped flat and assembled later, a rigid box is constructed from thick, non-collapsible paperboard. This makes it feel substantial and durable in the customer's hands. It’s an investment in quality that pays off by protecting both your product and your brand image. Let's look at why they are the go-to choice for premium goods.

Unmatched Structural Integrity

The fundamental benefit is strength. Rigid boxes are made from condensed paperboard, typically 1-3mm thick, wrapped in paper or other finishing materials. This construction makes them highly resistant to crushing and impact. I've worked on projects for delicate electronics and glass-bottled spirits where anything less than a rigid box would be a gamble. This durability ensures the product arrives in the same pristine condition it left the factory in.

Boosting Perceived Value

A product's perceived value is heavily influenced by its packaging. When a customer receives a product in a heavy, well-constructed rigid box, they immediately assume the item inside is of high quality. This premium feel justifies a higher price point and positions your brand in the luxury segment. It’s a psychological cue that works every time.

Sustainability Through Reusability

While the initial production might be more resource-intensive, rigid boxes have a strong sustainability story rooted in reusability. Customers rarely throw these boxes away. They become keepsake boxes for jewelry, documents, or other small items. This extended lifecycle keeps your brand present in the customer's home for months or even years.

| Feature | Rigid Box | Folding Carton | Corrugated Box |

|---|---|---|---|

| Protection | Excellent | Fair | Good |

| Premium Feel | Excellent | Good | Fair |

| Reusability | High | Low | Low |

| My Take | Best for luxury and fragile items | Best for lightweight retail goods | Best for e-commerce shipping |

What are the disadvantages of rigid boxes?

Are you considering rigid boxes but worried about the hidden costs and logistical hurdles? Their premium nature comes with trade-offs that can strain budgets and complicate supply chains if not planned for.

The main disadvantages of rigid boxes are higher production costs compared to folding cartons and increased shipping and storage expenses because they are delivered fully assembled. They also typically require longer production lead times due to their complex, hands-on manufacturing process.

It's crucial to have a clear picture of the downsides. In my experience, the sticker shock on a quote for rigid boxes can be a surprise if you're used to ordering folding cartons. The key is to understand where these costs come from so you can decide if the benefits truly outweigh them for your specific product and market. Let's break down these challenges.

Higher Unit Cost1

Rigid boxes are more expensive to produce. The materials, like thick greyboard, are costlier, and the manufacturing process involves more manual labor and specialized machinery for cutting, gluing, and wrapping. Unlike a folding carton that is produced in one pass on a single machine, a rigid box goes through several steps. This increased complexity and labor directly translate to a higher cost per unit.

Shipping and Storage Inefficiency2

This is a major logistical challenge. Since rigid boxes don't fold flat, they take up significantly more space. This means higher costs for both inbound shipping from the factory and warehousing. A single pallet can hold tens of thousands of flat-packed folding cartons, but only a few hundred assembled rigid boxes. You need to factor this "shipping air" into your total cost.

Longer Production Timelines3

The multi-step manufacturing process also means longer lead times. Setting up the machinery, wrapping the boxes, and allowing time for the glue to cure all add up. While a simple folding carton order might take a couple of weeks, a custom rigid box project can often take a month or more from final design approval to delivery. This requires more careful planning in your product launch schedule.

| Cost Factor | Description | Impact on Final Price |

|---|---|---|

| Materials4 | Thicker paperboard and premium wrap papers. | High |

| Labor5 | More hands-on assembly and finishing required. | High |

| Tooling6 | Requires custom dies for cutting the board and wrap. | Medium |

| Shipping | Boxes ship assembled, taking up more volume. | High |

What is the advantage of rigid containers?

In a crowded, high-end market, how do you ensure your product doesn't just blend in? A great product can get lost on the shelf if its packaging fails to capture attention.

The primary advantage of a rigid container is its ability to double as a display case or a permanent storage solution. This enhances the product's retail presence and provides lasting, tangible value to the consumer, which helps to reinforce brand loyalty long after the purchase.

Think of it this way: you’re not just selling a product; you’re selling an experience and an artifact. A well-designed rigid container is more than packaging—it's part of the product itself. I've always told my clients that when the box is too good to throw away, you've won. It becomes a constant, physical reminder of your brand's quality and elegance.

Creating a Stage for Your Product7

On a retail shelf, a rigid container commands attention. Its sharp edges, substantial weight, and beautiful finishes make it stand out against flimsier packaging. When opened, the box can be designed to present the product dramatically. Think of an iPhone box: the lid lifts slowly with air pressure, revealing the device perfectly nestled inside. The box acts as a stage, making the product the star of the show.

From Packaging to Keepsake8

Because of their durability and beauty, people keep these boxes. They become organizers on a desk, storage for jewelry in a drawer, or a safe place for cherished items. This act of keeping and reusing the box extends its life and your brand's visibility. Every time the customer uses that box, they are reminded of your product. It’s a powerful form of long-term marketing that you just don't get with disposable packaging.

Ideal for High-Value Industries9

This combination of protection, presentation, and perceived value makes rigid containers essential for certain industries. For luxury goods, the packaging is an inseparable part of the brand promise. It confirms the customer's decision to purchase a premium item and validates the high price tag they paid.

| Industry | Key Advantage of Rigid Container |

|---|---|

| Consumer Electronics10 | Protection, tech feel, and a premium unboxing experience. |

| Luxury Cosmetics | Elegance, ideal for gifting, and creates a sense of ritual. |

| High-End Spirits | Conveys brand prestige and protects a fragile, heavy product. |

| Jewelry & Watches | Provides security, doubles as a display case, and becomes a keepsake. |

Conclusion

By adding security and usability features, rigid boxes become more than packaging. They turn into a key part of your product, improving protection, branding, and the overall customer experience.

-

Understanding the cost factors can help you make informed decisions about packaging options. ↩

-

Explore this to grasp the logistical challenges and potential savings in packaging. ↩

-

Learn about the manufacturing process to better plan your product launches. ↩

-

Discover the impact of material choice on packaging quality and cost. ↩

-

Understanding labor costs can help you evaluate the overall value of rigid packaging. ↩

-

Gain insights into the custom tooling required for high-quality packaging. ↩

-

Explore how packaging design enhances product presentation and customer experience. ↩

-

Learn how packaging can extend brand visibility and customer loyalty. ↩

-

Discover how rigid packaging is essential for luxury and high-value products. ↩

-

Understand the unique benefits of rigid packaging in the tech industry. ↩