Worried about damaged products and a messy presentation? This can harm your brand and increase costs. Custom box inserts secure your items, ensuring they arrive safely and beautifully.

The best uses for custom box inserts are to protect fragile items, improve product presentation, organize multiple components, and enhance the unboxing experience. They are essential for electronics, cosmetics, luxury goods, and subscription boxes, adding both security and perceived value to your packaging.

I've seen firsthand how the right insert can transform a simple box into a memorable experience. With over 16 years in this industry, the small details are what separate good packaging from great packaging. But before we dive deep into the world of inserts, it's important to understand the broader context. Let's start with the foundation: the custom box itself. Understanding its benefits is the first step to mastering your packaging strategy1 and making sure your inserts have the perfect home.

What are the benefits of custom box2es?

Struggling with generic boxes that don't fit your products properly? This can lead to damage and a weak brand impression. Custom boxes offer a perfect fit and a powerful branding tool.

The main benefits of custom boxes are enhanced product protection, a stronger brand identity, and a better customer experience3. They are designed to fit your product perfectly, which reduces shipping costs by minimizing size and weight, and they serve as a powerful marketing tool.

As a packaging designer4, you know that the container is more than just a container. It's the first physical interaction a customer has with a brand. I remember working with a client who sold delicate, handmade glassware. They were using standard boxes with tons of bubble wrap, but breakages were common and their packaging felt cheap. Switching to a custom-fit box immediately solved the problem and elevated their brand. This is where the real benefits lie.

Superior Protection

A box designed to the exact dimensions of your product minimizes movement during transit. Less movement means less risk of scratches, dents, or breakage. It also reduces the need for excessive void-fill materials5 like peanuts or air pillows, which can lower your material costs and be better for the environment.

A Powerful Branding Tool

A custom box2 is your canvas. You can print your logo, use your brand colors, and add custom messaging. It turns a simple brown box into a mobile billboard that builds brand recognition from the doorstep to the moment of unboxing. It tells a story of quality and attention to detail before the customer even sees the product.

Improved Customer Experience

A well-designed custom box2 creates a premium unboxing experience6. It feels thoughtful and intentional. Just look at the difference in perception between a standard box and a fully custom one.

| Feature | Standard Box | Custom Box |

|---|---|---|

| Fit | Generic / Poor | Perfect / Secure |

| Protection | Low / Requires Extra | High / Integrated |

| Branding | None / Limited | Full / High-Impact |

| Customer Perception | Basic / Cheap | Premium / Thoughtful |

What are packaging inserts7?

Do your products move around inside their box during shipping? This can cause damage and make your brand look unprofessional. Packaging inserts are the solution for securing everything perfectly.

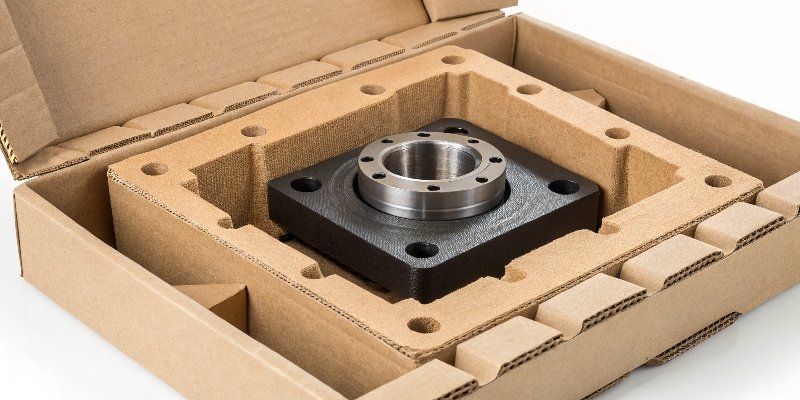

Packaging inserts, also known as dunnage, are custom-designed components placed inside a box. Their purpose is to secure, cushion, and organize products during shipping. They prevent movement, absorb shock, and enhance the visual presentation of the items when the box is opened.

Now that we see the value of a custom box2, let's look inside at its most important partner: the insert. An insert is the unsung hero of packaging. It does the hard work of protecting and presenting your product. As a designer, your choice of insert material and design is critical to the success of the entire package. The function of the insert determines everything.

The Function of an Insert

An insert’s job is more than just filling empty space. It serves three key roles:

- Protection: It cushions the product from shocks, vibrations, and compression that happen during shipping.

- Organization: It neatly holds multiple components, like a product with its cables, accessories, and manual. This is vital for kits and sets.

- Presentation: It displays the product in an attractive way, creating a "wow" moment when the customer opens the box. This elevates the unboxing experience6 from simple to special.

Common Materials for Inserts

The material you choose depends on the product's needs and your brand's values. Here is a quick breakdown to help you decide.

| Material | Best For | Pros | Cons |

|---|---|---|---|

| Corrugated Cardboard | Versatility, cost-effectiveness | Recyclable, very customizable | Can feel less premium than other options |

| Molded Pulp | Eco-friendly protection | Sustainable, great for odd shapes | Texture is rough, fewer sharp details |

| Foam (PE, EPE, EVA) | High-value, fragile items8 | Excellent shock absorption | Often less eco-friendly, can be costly |

| Thermoformed Plastic | Retail display, clear view | Durable, great for visual display | Fossil fuel-based, recycling can be limited |

What is an insert Box?

Selling a product with many different components? These pieces can get jumbled and look messy. An insert box keeps every part perfectly organized and presented in one cohesive package.

An insert box is a packaging solution where the custom insert is an integral part of the box's structure or design. Rather than a separate piece, it's a unified system designed to hold specific items securely, making it ideal for product kits, gift sets, or electronics.

This is a subtle but very important distinction for a designer. An insert box isn't just a box with an insert; it’s a single, cohesive packaging system. Think of a high-end electronics box where the tray holding the phone is built into the overall structure, or a board game box where the organizer is part of the box itself. We often design these for luxury brands where the unboxing flow is critical. The reveal has to be perfect, and an integrated design makes that possible.

Integrated vs. Separate Inserts

A separate insert is a piece you add to a box. For example, you might place a foam insert inside a standard mailer box. An integrated insert is designed with the box, often created from the same piece of material. Imagine a single sheet of paperboard that is die-cut and folded to create both the outer box structure and the inner compartments. This approach creates a seamless, high-end feel and can be very efficient for assembly.

When to Choose an Insert Box

An integrated insert box9 is the best choice when presentation and user experience are top priorities. It's not just about protection; it's about storytelling. Consider it for:

- Luxury Gift Sets: Holding a bottle and glasses in place perfectly.

- Product Kits: Guiding the user through different components in a specific order.

- Subscription Boxes: Where the curation and organization are a key part of the value proposition.

- Complex Electronics: Keeping a device, charger, and cables neat and easy to access.

What are shipping inserts10?

Shipping can be a rough journey for your products. Standard void fill isn't always enough to prevent damage. Shipping inserts are engineered specifically to cushion and protect during transit.

Shipping inserts are protective materials designed primarily for transit security, often called dunnage. Their main job is to brace, cushion, and absorb shock to prevent damage. While they can improve presentation, their core function is protection, unlike display-focused inserts.

While a beautiful presentation is great, it means nothing if the product arrives broken. This is where shipping inserts10 come in. Their design is less about looks and all about performance. For a designer, this is a technical challenge: how do you create the most protection with the least material, cost, and weight? I once worked with an e-commerce client whose return rate for a fragile product dropped by 80% after we designed a simple but effective custom corrugated insert. It wasn't fancy, but it was incredibly effective because it was engineered for one job: survival.

Protection Over Presentation

Shipping inserts are designed to counter the specific hazards of a supply chain: shocks from drops, constant vibration on a truck, and compression from stacking. The materials are chosen for their performance characteristics. For example, you might use a high-density polyethylene (PE) foam for heavy, sensitive equipment because it provides excellent cushioning and can withstand multiple impacts. Engineered corrugated structures are another fantastic option—they can be designed to create a suspension system within the box, all while being lightweight and recyclable.

Designing for the Supply Chain

A great shipping insert isn't just protective; it's practical. It needs to be easy for warehouse staff to use quickly and correctly. It should also be designed to minimize dimensional weight, as carriers like FedEx and UPS charge based on size as well as weight. A well-designed shipping insert achieves these key goals:

- Immobilizes the product completely.

- Absorbs impact energy effectively.

- Distributes weight and pressure evenly.

- Is cost-effective and efficient for packing operations.

Conclusion

Custom inserts are vital for protection, branding, and customer delight. From simple dividers to engineered systems, the right insert adds immense value and secures your product's journey to the customer.

-

Learn how to create a comprehensive packaging strategy that aligns with your brand and product needs. ↩

-

Learn about the benefits of custom boxes in enhancing product protection and brand identity. ↩ ↩ ↩ ↩

-

Discover how thoughtful packaging design can significantly enhance the overall customer experience. ↩

-

Learn about the key skills and knowledge areas that make a successful packaging designer. ↩

-

Explore effective void-fill materials that can protect products while being cost-effective and eco-friendly. ↩

-

Find out how to create a delightful unboxing experience that leaves a lasting impression on your customers. ↩ ↩

-

Explore various types of packaging inserts and their roles in securing and presenting products effectively. ↩

-

Learn effective strategies to safeguard fragile items, minimizing damage and enhancing customer satisfaction. ↩

-

Discover the advantages of using integrated insert boxes for a seamless and premium packaging experience. ↩

-

Understand the function of shipping inserts in protecting products during transit and reducing damage. ↩ ↩