Standing out is tough when every box looks the same. Your great product gets lost on the shelf, failing to grab attention. Cardboard tubes offer a unique, memorable alternative.

Cardboard tubes are a prime choice for unique packaging because their cylindrical shape inherently differentiates your product on the shelf. They provide excellent structural protection, a premium feel for unboxing, and can be fully customized, elevating brand perception far beyond a standard rectangular box.

The unique shape of a tube is just one part of the story. The real hero behind this innovative format is the material itself: cardboard. It’s the foundation for so many of today's best packaging solutions, from simple shippers to high-end retail boxes. As a packaging professional with over 16 years in the business, I've seen firsthand how versatile and effective it can be.

So, before we look closer at tubes, let's explore why cardboard is such a dominant force in our industry. Understanding its core strengths is key to making smarter packaging decisions. It’s a foundational question I discuss with my clients and design team almost every single day. Let's get into it.

Why is corrugated cardboard a good material choice for packaging a product?

You need strong packaging, but heavy materials increase shipping costs and eat into your budget. This hurts your bottom line and your brand's commitment to sustainability. Corrugated cardboard solves this.

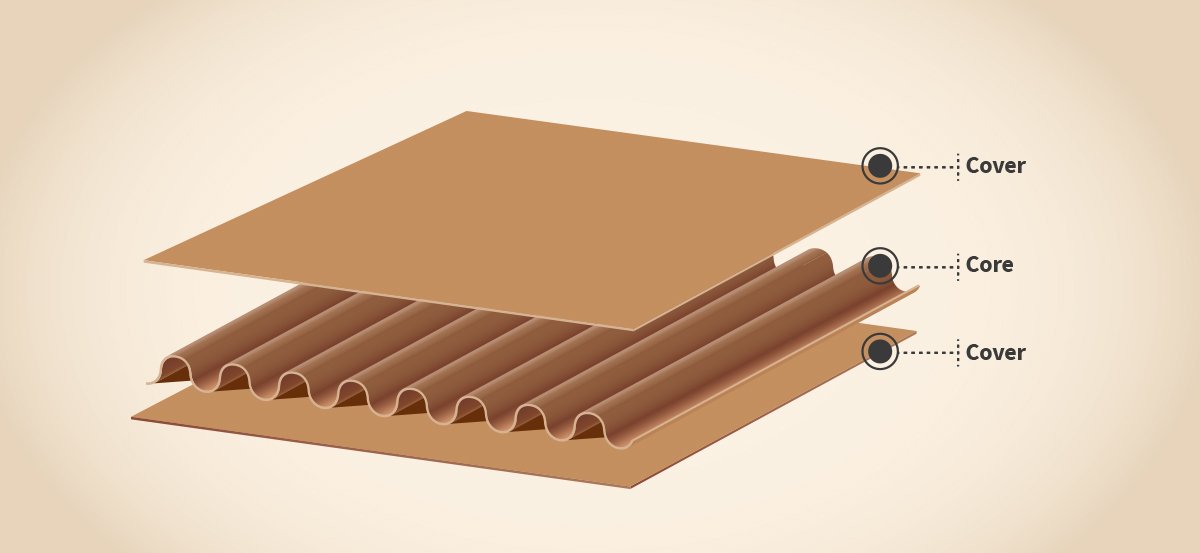

Corrugated cardboard is an excellent material because its unique fluted layer, sandwiched between two liners, creates impressive strength and cushioning while remaining remarkably lightweight. This structure effectively protects products during transit, is cost-effective to produce and ship, and is highly recyclable.

When designers like you think about protection, corrugated cardboard is often the first material that comes to mind, and for good reason. Its strength doesn't come from solid mass but from engineering. The "flute" is that zig-zag layer of paper in the middle. This simple design creates a series of connected arches, making the board remarkably resistant to bending and pressure. I remember a project for a company shipping delicate glass bottles. They were convinced they needed expensive foam inserts. Instead, we designed an interior fitting using a double-wall B/C flute corrugated board. It held the bottles perfectly, absorbed shock during drop tests, and cut their packaging cost by nearly 40%. The client was amazed. The genius is in the different flute profiles, each serving a distinct purpose.

| Flute Profile | Key Characteristic | Common Application |

|---|---|---|

| E Flute | Very thin, excellent print surface | Retail boxes, cosmetic packaging, pizza boxes |

| B Flute | Good balance of crush resistance and printability | Inner packagings, displays, mailer boxes |

| C Flute | The most common, all-purpose shipper flute | Standard shipping cartons, master cartons |

By understanding and combining these different types, we can create packaging that is perfectly tailored to the product's journey from our factory to the customer's hands.

What are the advantages of cardboard box packaging?

You have a new product line, but the budget is tight and deadlines are even tighter. Custom solutions feel too expensive or complex, pushing you toward generic boxes that don't represent your brand.

The main advantages of cardboard box packaging are its unmatched affordability, versatility, and sustainability. It is lightweight, which lowers shipping costs, yet strong enough for solid protection. It's also fully customizable with printing and finishes, and is easily recycled by consumers.

In my years of running Giftspack, the conversation with clients almost always touches on three key areas: cost, brand presentation, and environmental impact. Cardboard delivers on all three fronts, which is why it remains so popular. Its cost-effectiveness comes from inexpensive raw materials and highly efficient manufacturing processes. For many startups I work with, this is the single most important factor that allows them to launch with professional-looking packaging without breaking the bank.

Then there’s versatility1. This is where designers like you really get to shine. Cardboard is a blank canvas. We can apply simple one-color flexo printing for a minimalist look or go all out with multi-color offset printing for photo-realistic graphics. We can add finishes like matte or gloss lamination, spot UV to highlight a logo, or elegant foil stamping. The structural possibilities are also nearly endless, from a simple mailer box to a complex multi-part unboxing experience2.

Finally, its sustainability3 is no longer a "nice-to-have" but a core requirement. Cardboard is primarily made from a renewable resource4—trees from sustainably managed forests—and has one of the highest recycling rates of any material. Consumers understand and appreciate this. They can easily flatten a box and put it in their recycling bin, feeling good about their purchase and your brand.

Why is cardboard used in packaging?

Choosing a packaging material requires a delicate balance of cost, product protection5, brand image, and sustainability3. Making the wrong choice can lead to damaged goods, inflated budgets, or a negative perception from customers.

Cardboard is used so widely in packaging because it provides an ideal and proven combination of strength, affordability6, and customizability7. It reliably protects goods during shipping, keeps costs low for both production and logistics, and serves as an excellent medium for branding.

The question of "why cardboard" goes beyond a simple list of benefits. It's about its role across the entire product lifecycle, from the factory floor to the customer's home. I see it as the ultimate problem-solver in packaging.

The Practical Choice for Operations

From a logistics perspective8, cardboard is a dream material. It can be shipped and stored flat, which saves an incredible amount of warehouse space compared to pre-formed plastic or metal containers. This efficiency translates directly into lower overhead costs. Assembly can be done by hand or with high-speed automated equipment. A client of mine in the subscription box industry was able to scale their operations rapidly because the die-cut mailers we provided were easy for their team to fold and pack quickly, without needing complex machinery at the start.

The Flexible Choice for Branding

Cardboard adapts to the brand's identity, not the other way around. For a natural, organic brand, we can use raw kraft board with simple black print to communicate an earthy, eco-friendly message. For a luxury tech brand, we might use a rigid greyboard wrapped in soft-touch laminated paper with embossed details. The material itself doesn't lock you into one specific look or feel; it's the design and finishing that define the brand experience.

The Smart Choice for Consumers

Ultimately, packaging has to work for the end user. Cardboard is familiar, intuitive, and easy to handle. It facilitates the "unboxing experience2" that has become so crucial for e-commerce brands. It's also easy to dispose of responsibly. No one feels good about throwing away a large, bulky plastic clamshell. Flattening a cardboard box for recycling is a simple, guilt-free action that leaves a positive final impression of the brand.

Why is cardboard regarded as one of the best?

In a world filled with high-tech polymers and advanced materials, it can be easy to overlook a classic like cardboard. You might wonder if it's still the best choice or if you're missing out.

Cardboard is regarded as one of the best packaging materials because it offers an unmatched balance of high performance9, low cost, and strong environmental credentials10. No other material provides such a high degree of versatile customization, printability, and strength-to-weight ratio at such an accessible price point.

Calling something "the best" is a bold claim, but in the world of packaging, cardboard has earned that reputation by consistently outperforming other materials in the areas that matter most to businesses and consumers. While materials like plastic or metal certainly have their specific uses, they often involve significant trade-offs. For a project designer like you, understanding these trade-offs is crucial. Cardboard’s magic lies in its ability to avoid major compromises. Let's look at a simple comparison.

| Feature | Cardboard | Rigid Plastic | Metal (Tin) |

|---|---|---|---|

| Cost | Low | Medium | High |

| Weight | Low | Medium | High |

| Brand Customization | Very High (Shape, Print, Finish) | Moderate (Shape, Color) | Low (Mainly Labels) |

| Sustainability | High (Renewable, Recyclable) | Low-Medium (Often not Recycled) | Medium (Recyclable, High Energy Use) |

| Consumer Perception | Versatile (Eco to Premium) | Mass-Market, Less Premium | Durable, Collectible, Premium |

As you can see, cardboard consistently hits a sweet spot. It provides the robust protection needed for logistics, the endless branding canvas needed by marketing, the cost-efficiency required by finance, and the sustainable profile demanded by modern consumers. When we then take all these fundamental benefits and apply them to a unique form factor like a cardboard tube, we create something truly special—packaging that is protective, cost-effective, sustainable, and visually distinct. That's why, after all these years, I still see cardboard as the king of packaging materials.

Conclusion

Cardboard packaging, especially in unique forms like tubes, offers an unbeatable mix of protection, branding power11, and sustainability3, making it a smart and effective choice for almost any product.

-

Explore how versatility in packaging can enhance brand identity and customer experience. ↩

-

Delve into the unboxing experience and its role in customer satisfaction and brand loyalty. ↩ ↩

-

Learn about the significance of sustainability in packaging and its impact on consumer choices. ↩ ↩ ↩

-

Find out how cardboard's renewable nature contributes to its sustainability and appeal. ↩

-

Understand the protective qualities of cardboard that ensure goods arrive safely. ↩

-

Find out why cardboard is a cost-effective choice for businesses looking to optimize their packaging. ↩

-

Discover how customizability can elevate your brand's packaging and attract more customers. ↩

-

Learn how cardboard's properties streamline logistics and reduce costs for businesses. ↩

-

Understand the characteristics that make cardboard a high-performance packaging material. ↩

-

Explore the eco-friendly aspects of cardboard that appeal to environmentally conscious consumers. ↩

-

Discover the ways in which effective packaging can strengthen brand recognition and appeal. ↩