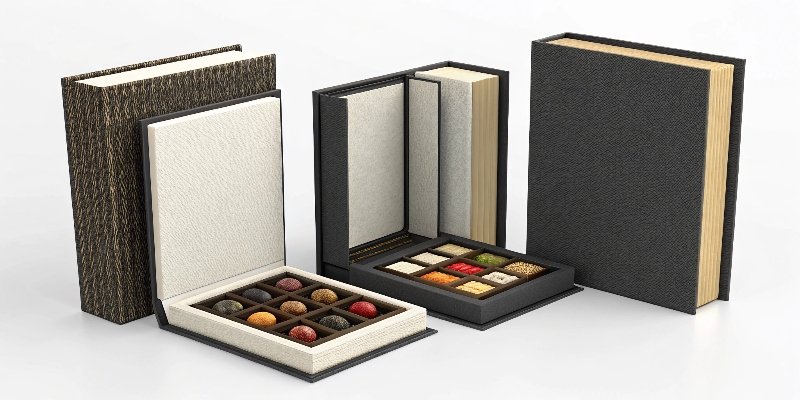

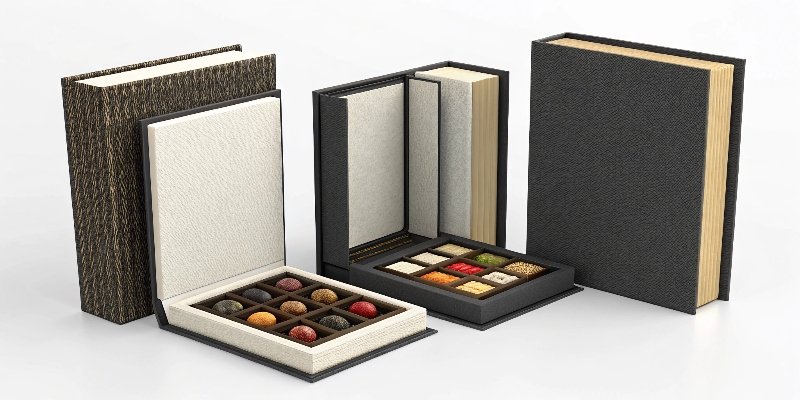

Finding packaging that feels truly special is tough. A standard box is often overlooked, failing to create a memorable moment for your customer. Book-style boxes deliver that "wow" factor.

Book-style rigid boxes are most popular for high-end products like luxury cosmetics, premium electronics, gourmet foods, and special edition collections. Their unique, book-like opening and sturdy construction create a sophisticated unboxing experience that significantly elevates perceived brand value.

The appeal of these boxes is clear from the moment you see one. They promise something valuable is inside. But their good looks are just the beginning. The real value comes from a combination of strength, brand perception, and the experience they create. Over my 16 years in this industry, I've seen brands transform their customer loyalty just by switching to a better box. Let's explore why these boxes are so effective and what you need to consider before choosing them for your own products.

What are the benefits of rigid boxes?

Your product is great, but it needs packaging that offers both protection and a premium look. Flimsy boxes can lead to damage and make your brand feel cheap.

The primary benefits of rigid boxes are superior product protection1, a high-end feel2 that boosts brand value, and extensive customization options3. They provide a memorable unboxing experience4 and are often kept by customers for reuse.

[^5].](http://gifts-pack.com/wp-content/uploads/2025/07/The-Power-of-Luxury-Packaging.jpg)

When clients ask me why they should invest in rigid boxes, I always talk about three things: strength, perception, and possibilities.

First, the strength is unmatched. These boxes are made from thick, dense paperboard, sometimes up to 3mm thick. This isn't like a standard retail carton. It’s solid. I’ve seen products shipped across the world in these boxes, and they arrive perfectly intact, even when the outer shipping carton has taken a beating. This protection gives you peace of mind.

Second is perception. A rigid box feels substantial in a customer's hands. The weight, the smooth finish, the crisp edges—it all sends a message of quality before they even see the product. Adding finishes like soft-touch lamination5 or a magnetic closure6 turns the opening into a small ceremony.

Finally, the customization possibilities are nearly endless. You aren't just printing on a box; you are building a complete experience.

| Customization Feature | Description | Benefit for Your Brand |

|---|---|---|

| Custom Inserts | Foam, molded pulp, or paperboard compartments | Securely holds products, creating a clean presentation. |

| Closure Systems | Concealed magnets, elegant ribbons, or friction-fit | Adds a satisfying tactile element to the unboxing. |

| Surface Finishes | Embossing, foil stamping7, spot UV, laminations | Creates visual and textural appeal that screams luxury. |

What are the disadvantages of rigid boxes?

You are thinking about using rigid boxes for your product. But you might be worried about some hidden costs or logistical problems that could come with them.

The main disadvantages are a higher cost per unit8 compared to other packaging, the need for more storage space as they arrive pre-assembled, and longer production times. Their weight can also increase shipping expenses.

I believe in being honest with my clients, and rigid boxes are not the right fit for every project. The first thing to consider is the cost. Because they use more material and require more hands-on assembly, a rigid box can easily cost several times more than a standard folding carton. This investment needs to make sense for your product's price point and brand positioning.

Another major factor is logistics9. Rigid boxes do not ship flat. This is a point I always emphasize. A single pallet might hold 20,000 flat-packed folding cartons, but that same pallet might only fit 1,000 assembled rigid boxes. You need to have the warehouse space10 to store them before they are filled with products. I once had a startup client who was shocked at how much room their first order took up. Planning for storage is critical.

Finally, you need to account for time. The process of making a rigid box is more involved than for a folding carton. Cutting the chipboard, assembling the structure, and carefully wrapping it with the printed paper takes time. This means lead times11 are longer, so you can't place a rush order and expect it in a week.

What is an example of a rigid box?

You often hear the term "rigid box" in the packaging world. But it can be hard to picture exactly what that means when making design choices.

A classic example of a rigid box is the packaging for a new Apple iPhone. It is a "telescope" style box with a separate lid and base, made from thick, sturdy paperboard with a premium, minimalist finish.

The smartphone box is the example everyone knows, but the world of rigid boxes is much broader. As a designer, knowing the different styles helps you match the right structure to the product and the desired unboxing experience4. The focus of this article, the book-style box, is one of my favorites.

Here are a few common styles I regularly produce for my clients:

- Book-Style Box: This style, also called a clamshell box, is hinged on one side and opens like a book. It often uses a magnetic closure6 to create a satisfying snap when it closes. I've designed these for luxury skincare sets and special edition corporate gifts. The reveal feels very deliberate and elegant.

- Telescope Box (Lid and Base): This is the iPhone box. It can be a full telescope, where the lid covers the entire base, or a partial telescope with a shorter lid. The precise fit creates air pressure, so the lid slides off slowly. It’s perfect for creating anticipation.

- Drawer Box (Slipcase): This design features a sleeve with an inner tray that slides out, much like a matchbox. We often add a ribbon pull-tab to make it easier to open. This style is very popular for jewelry, watches, and high-end confectionery. The sliding action adds a fun, interactive element for the customer.

What is the difference between a rigid box and a folding box?

You need to choose between a rigid box and a folding box for your product. Picking the wrong option can negatively affect your budget, your timeline, and your brand's image.

The main difference lies in material and construction. Rigid boxes use thick, non-collapsible chipboard and arrive pre-assembled. Folding boxes are made from a single sheet of paperboard, which is shipped flat and assembled later.

When I consult with a designer like Peter, the decision between a rigid box and a folding box is fundamental. It comes down to balancing impression with practicality. I always ask them, "Are you looking for packaging that simply contains the product, or do you want the packaging to be part of the product experience?" Their answer usually points us in the right direction.

To make it simple, let's break down the key differences in a table. I use this framework with clients every day to help them clarify their needs.

| Feature | Rigid Box | Folding Box (Carton) |

|---|---|---|

| Material | Thick chipboard (1-3mm) wrapped with paper. | A single layer of thinner paperboard. |

| Strength | Extremely durable and protective. | Lighter protection, suitable for most retail goods. |

| Construction | Arrives pre-assembled and solid. | Ships flat and requires assembly before filling. |

| Appearance | High-end, luxury feel with sharp corners. | Good for printing, but looks more standard. |

| Storage | Requires significant warehouse space10. | Very space-efficient, as they are stored flat. |

| Cost | Higher initial investment per unit. | Much more cost-effective, especially in bulk. |

A folding box is the workhorse of retail. It's efficient and does its job well. A rigid box is a statement. It’s an investment in your brand’s story and your customer’s first impression.

Conclusion

Book-style rigid boxes offer powerful branding through a premium feel. Though they cost more, their protective quality and superior unboxing experience4 deliver great value for high-end products.

-

Learn why product protection is crucial for maintaining quality and customer trust. ↩

-

Discover how packaging design can convey luxury and enhance brand value. ↩

-

Explore various customization options that can make your packaging stand out. ↩

-

Explore the importance of unboxing experiences in customer satisfaction and brand loyalty. ↩ ↩ ↩

-

Learn how soft-touch lamination can add a luxurious feel to your packaging. ↩

-

Find out how magnetic closures can improve the functionality and appeal of packaging. ↩ ↩

-

Discover the visual impact of foil stamping and how it can elevate your brand. ↩

-

Explore how packaging costs can impact your overall product pricing strategy. ↩

-

Understand the logistical considerations when choosing rigid boxes for your products. ↩

-

Learn about the storage implications of using rigid boxes for your products. ↩ ↩

-

Find out how production timelines can affect your packaging strategy. ↩