Struggling with the specifics of CBD packaging? The right box is vital for product safety, compliance, and your brand's image. I will help you master using cardboard CBD boxes.

Using cardboard CBD packaging involves choosing the correct style for your product, folding it properly, and designing it to meet legal and marketing requirements. This ensures your product is protected, compliant with regulations, and appealing to customers, which builds brand trust.

Over my 16 years in the packaging industry1, I've seen many brands grapple with the unique challenges of CBD products. It's a field where the packaging is almost as important as the product inside. It's not just about creating a pretty box; it's about building a vessel of trust, safety, and quality for your customer. Getting it right from the start can make all the difference in a competitive market. Let's break down the essential steps to ensure your CBD packaging2 works for you, not against you.

How to fold cardboard boxes for packing?

Folding a box seems easy, but getting it wrong can be a real problem. An improperly folded box is weak and puts your valuable CBD product at risk during shipping and handling.

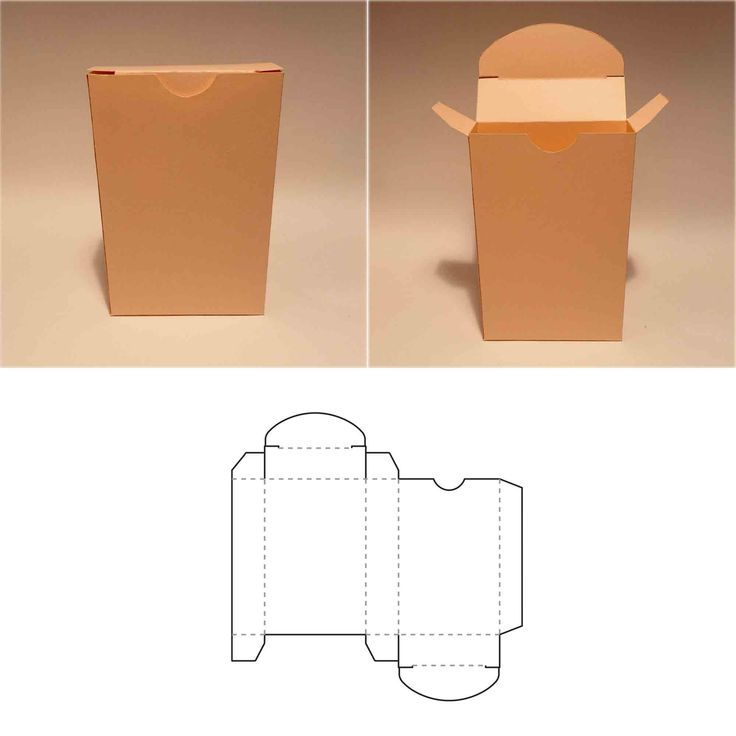

To fold cardboard boxes correctly, you should start with the flat, die-cut sheet. Always pre-crease the score lines to make folding clean and easy. Assemble the bottom structure first to create a stable base, then fold up the sides before placing your product inside and closing the top.

In my experience, the moment a box goes from flat to three-dimensional is critical. It sets the foundation for the product's entire journey. For packaging designers3, understanding this physical process is key to creating designs that are not only beautiful but also practical. The first step is always to gently bend every single pre-scored line. This breaks the paper's "memory" and ensures sharp, clean folds. Rushing this step often leads to a sloppy, weak box. Next, focus on the base. Different box styles have different locking mechanisms. For example, a tuck-end box is simple, but a snap-lock bottom (or 1-2-3 bottom) offers much more strength for heavier items like glass tincture bottles. As a designer, you have to balance the complexity of assembly with the level of security needed.

Here’s a simple breakdown of common assembly types:

| Box Style | Assembly Difficulty | Best Use Case |

|---|---|---|

| Straight Tuck End | Easy | Lightweight items, like vape cartridges. |

| Reverse Tuck End | Easy | Similar to straight tuck, very common. |

| Snap-Lock Bottom | Medium | Heavier items, glass bottles, jars. |

| Mailer Box | Medium | E-commerce shipping, subscription kits. |

Always ensure the box is square after folding. A twisted box doesn't just look bad; it also creates pressure points that can damage the product inside.

What is a CBD box?

You hear the term "CBD box" all the time, but are you sure what makes it different? It is much more than a standard container. It carries special responsibilities that other boxes do not.

A CBD box is a piece of specialized packaging made to hold cannabidiol products. Its main jobs are to protect the product, follow very strict legal and labeling rules, often have child-resistant features4, and clearly show brand quality and trust in a crowded market.

When a client asks me for a CBD box, I know they need much more than just four walls and a lid. This type of packaging has to perform several critical jobs at once. For a designer, it’s a fascinating challenge to balance all these needs. We have to think about protection, compliance5, and branding all at the same time. These three pillars are what truly define a CBD box and separate it from general packaging. Forgetting even one of them can lead to serious problems for the brand, from damaged products to legal issues. I've helped countless clients navigate these areas, and it always starts with understanding that the box is an active part of the product experience.

Protection

CBD products often come in fragile containers6 like glass dropper bottles, small jars, or vape cartridges. The box is their first line of defense. We often design custom inserts made from cardboard or foam. These inserts hold the product securely in place, stopping it from moving around and breaking during transit. The outer cardboard must also be strong enough to withstand bumps and drops.

Compliance

This is the most complex part. CBD regulations change depending on where you sell your product. A compliant box must have space for a lot of information. This includes batch numbers, manufacturing dates, QR codes linking to lab results (Certificates of Analysis), and clear warnings about THC content. Some regions also require child-resistant (CR) mechanisms, which adds another layer of engineering to the box design.

Branding

In a market with so many options, the box is your silent salesperson. The design needs to connect with your target customer instantly. Some brands choose a minimal, medical look to build trust. Others go for natural, earthy tones to highlight the product's origins. Premium finishes like embossing, foil stamping, or soft-touch coatings can make the product feel more valuable and luxurious. The unboxing experience7 is your chance to make a lasting impression.

What is the full form of CBD in packaging?

You see the letters "CBD" everywhere, but do you know what they stand for? Knowing the full term is the first step, but understanding what it means for packaging is even more important.

In packaging, CBD stands for Cannabidiol8. While that is the literal name, for a packaging professional, the term "CBD" also signals a specific category of packaging. This category has its own set of rules for safety, legal compliance5, and marketing that are very demanding.

The full term is Cannabidiol8. It is a natural compound found in the cannabis plant. But in my world, the packaging industry1, those three letters mean much more. When I hear "CBD project," a mental checklist immediately starts. I know the project will have unique challenges that we don't face with something like a simple soap box. It tells me we need to be extra careful about the details. For a packaging designer, "CBD" is a code word for a project that requires a high level of expertise in materials, regulations, and consumer psychology. It’s not just about putting a plant-based product in a box; it’s about navigating a new and rapidly evolving industry with precision and care.

To show you what I mean, here is how CBD packaging2 compares to general product packaging:

| Feature | General Product Packaging | CBD Product Packaging |

|---|---|---|

| Legal Rules | Basic requirements (e.g., net weight). | Very strict state/federal rules, warnings. |

| Safety Features | Standard protection from damage. | Often requires certified child-resistant (CR) features. |

| Information | Brand name, product info, ingredients. | High density: lab results, QR codes, batch #, legal disclaimers. |

| Material Choice | Focus on cost and visual appeal. | Focus on security, premium feel, and sustainability to build trust. |

| Target Audience | Broad consumer base. | Often a health-conscious but cautious consumer. |

So, while the full form is Cannabidiol8, the practical meaning in my line of work is a project that demands our A-game. We have to be designers, legal experts, and safety engineers all wrapped into one.

Conclusion

Using CBD boxes correctly means folding them right, knowing their compliance5 role, and understanding the term's full meaning. Mastering these points is essential for your product's safety and market success.

-

Stay updated on the latest trends in the packaging industry, especially for CBD products. ↩ ↩

-

Explore this resource to learn essential tips and guidelines for effective CBD packaging that ensures safety and compliance. ↩ ↩

-

This link will highlight the essential skills and knowledge packaging designers must have for CBD products. ↩

-

Explore the importance of child-resistant features in packaging, especially for CBD products, to ensure safety. ↩

-

Gain insights into the complexities of compliance in CBD packaging and how to navigate them effectively. ↩ ↩ ↩

-

Learn effective strategies for packaging fragile items to prevent damage during transit. ↩

-

Discover how a well-designed unboxing experience can enhance customer satisfaction and brand perception. ↩

-

Explore the significance of Cannabidiol in the packaging industry and its implications for product design. ↩ ↩ ↩