Your products are valuable, but they are at risk inside a simple box. Mold can destroy your inventory, damage your brand reputation, and lead to significant financial losses.

To protect corrugated boxes from mold, you must control moisture and the storage environment. Use boxes with moisture-resistant coatings, ensure proper ventilation in your warehouse, and keep humidity levels below 50%. Always store boxes on pallets, never directly on concrete floors where moisture gathers.

This answer is the foundation for protecting your goods. But effective mold prevention involves more than just storage. It's about building a stronger, more resilient package from the very start. We need to look at the box's strength, the tools you can use inside it, and specific ways to shield it from moisture. Even knowing how to handle a mold outbreak is crucial. Let's dive deeper into each of these areas to build a complete protection strategy.

How to increase the compressive strength of a corrugated box?

Your boxes are collapsing under the weight of a full pallet. This leads to crushed products, unhappy customers, and costly returns that eat into your profits.

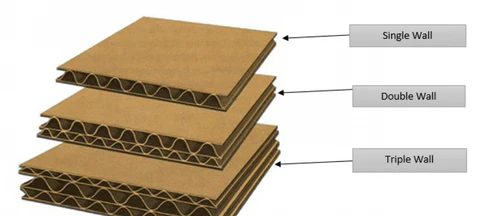

To increase the compressive strength of a corrugated box, use a stronger flute profile like C-flute1 instead of B-flute. You can also specify a heavier, higher-grade linerboard2 or upgrade from a single-wall to a double-wall construction3 for maximum stacking performance.

Key Factors in Box Strength

The strength of a box isn’t just about the paper. It's about how the components work together. For designers like Peter, understanding these details is essential for creating packaging that performs. The most important metric for stacking ability is the Edge Crush Test, or ECT4. This test measures the force needed to crush a box standing on its edge, which directly relates to how much weight it can support in a stack.

I always tell my clients to pay attention to the flute direction5. For maximum strength, the flutes must run vertically. I remember one client whose shipments kept arriving damaged. We discovered their previous supplier had cut the boxes with horizontal flutes to save material. This simple mistake cut the box's strength by over 60%. By correcting the flute direction5, we solved the problem and saved them thousands.

Here is a simple look at different flutes:

| Flute Profile | Stacking Strength | Cushioning | Print Surface | Common Use |

|---|---|---|---|---|

| C-Flute | Excellent | Good | Fair | The standard for shipping boxes. |

| B-Flute | Good | Fair | Good | Retail packaging, inner packaging. |

| E-Flute | Fair | Poor | Excellent | High-quality printed boxes, pizza boxes. |

| BC-Flute | Superior | Excellent | Fair | Double-wall for heavy items. |

Choosing the right combination of linerboard weight and flute profile is the key to designing a cost-effective box that won't fail.

What to put in storage boxes to prevent mold?

You are storing important products or documents for the long term. But hidden moisture in the air is a silent threat, causing musty smells and destructive mold growth.

To prevent mold inside storage boxes, add desiccants like silica gel packets6 or activated charcoal pouches7. These materials actively absorb moisture from the enclosed air. This keeps the internal humidity low and creates an environment where mold cannot grow.

Choosing the Right Desiccant

Putting something inside the box to fight moisture is a smart, proactive step. Think of it as an insurance policy. For a product designer, recommending the right desiccant can add significant value and protect the client's goods, especially for sensitive items like electronics or luxury leather goods. You have a few main choices, and each has its specific strengths.

For most commercial products, especially electronics, silica gel is the industry standard. It's clean, effective, and non-toxic. It works by adsorbing water vapor into its porous structure. For clothing or other textiles, activated charcoal is a fantastic option because it not only absorbs moisture but also traps odor molecules, keeping items smelling fresh. For heavy-duty industrial applications where humidity is very high, calcium chloride8 is the most powerful choice. It can absorb several times its own weight in water, but it eventually turns into a liquid brine, so it must be contained in a special pouch or tray.

Here’s a quick guide to help you choose:

| Desiccant | Best For | How it Works | Notes |

|---|---|---|---|

| Silica Gel | Electronics, leather, food | Adsorbs moisture | Reliable and widely available. Some types are reusable. |

| Activated Charcoal | Clothing, books, papers | Adsorbs moisture and odors | Excellent for preventing musty smells. |

| Calcium Chloride | Industrial parts, container shipping | Absorbs large moisture volumes | Extremely powerful. Requires careful handling as it becomes liquid. |

| Bentonite Clay | General goods, bulk items | Adsorbs moisture | An affordable and eco-friendly alternative to silica gel. |

Matching the right desiccant to the product and shipping conditions is a critical detail that protects the product all the way to the end customer.

How to protect cardboard boxes from moisture?

Your supply chain will inevitably face rain, humidity, and damp warehouses. A single moisture event can weaken your packaging, compromise your products, and damage your reputation.

To protect cardboard boxes from moisture, apply a barrier. You can use boxes with a wax or polymer coating. For shipments, wrap pallets tightly with stretch film. In storage, always keep boxes on pallets and away from damp walls and floors9.

Layers of Moisture Defense

Protecting a box from moisture requires a multi-layered approach. You can't just rely on one thing. In my 16 years in packaging, I've seen that the most successful strategies combine material science, smart handling, and a controlled environment.

First, let’s talk about the box itself. A product designer can specify a moisture-resistant board. There are two main types. Wax-impregnated board has wax blended into the paper fibers, offering deep protection against general humidity. It's great for agricultural products. The other type is a coated board10, which has a thin layer of plastic or polymer on the surface. This creates a barrier against direct splashes or light rain. The choice depends on the specific threat: ambient humidity or direct water contact.

Second, consider the unit load. No matter how good the box is, a full pallet needs an outer shield. Plastic stretch wrap is essential. It's cheap, effective, and holds the load together while providing an excellent water-resistant barrier.

Finally, think about the storage environment. I always tell my clients, "Think like water." It moves from wet to dry and settles at the lowest point. Concrete floors are notorious for wicking moisture upwards. Getting your boxes onto a pallet, even just a few inches off the ground, is the single most important action you can take in any storage situation. Keep them away from exterior walls, too.

How do you get mold out of cardboard boxes?

You've discovered mold on your boxes in the warehouse. Now you are worried the entire shipment is ruined and that the problem will spread if you don't act fast.

To remove light surface mold from a cardboard box, take it outside and wipe the spores away with a dry cloth. Then, lightly dampen another cloth with diluted white vinegar or isopropyl alcohol11 and wipe the area again. Let it air dry completely in the sun.

A Step-by-Step Cleaning and Assessment Guide

Finding mold is stressful, but it doesn't always mean total loss. However, you must handle it as a rescue mission, not a routine task. Safety and careful assessment are your top priorities.

First, protect yourself. Always wear gloves and a protective mask before handling moldy items. Mold spores are allergens and can be harmful if inhaled. Take the affected boxes outside or to a very well-ventilated area to prevent spores from spreading inside your facility.

Next, you have to assess the damage honestly. Is the mold just a light dusting on the surface, or has it penetrated the paper? Is the cardboard warped, soft, or stained all the way through? After more than a decade in this business, I've learned a hard lesson: it is better to discard a structurally compromised box12 than to risk the product inside. If the box feels weak, throw it away.

If it's only light surface mold, you can proceed with cleaning.

- Dry Wipe: Use a dry paper towel or cloth to gently brush the visible mold off the surface.

- Damp Wipe: Mix a solution of 50% white vinegar and 50% water. Lightly dampen a clean cloth with it—do not saturate the cardboard—and wipe down the affected area. The acid in the vinegar kills many common types of mold.

- Dry Completely: This is the most important step. The box must be 100% dry before you can even consider reusing it. Leave it in direct sunlight if possible, as the UV rays provide a mild disinfecting effect13.

Remember, cleaning is a last resort. The best strategy is always prevention.

Conclusion

Protecting your corrugated boxes is about proactive control over their entire lifecycle. By focusing on strength, moisture control, and proper handling, you ensure your products arrive safe and sound.

-

Explore why C-flute is preferred for shipping and how it enhances compressive strength. ↩

-

See how upgrading linerboard can prevent box collapse and protect your goods. ↩

-

Double-wall boxes offer superior stacking strength—learn when and why to use them. ↩

-

ECT is the key metric for stacking performance—understand how it affects your packaging. ↩

-

Correct flute orientation can make or break your packaging—learn how to get it right. ↩ ↩

-

Silica gel is a simple, effective solution for moisture control—see how it works. ↩

-

Activated charcoal not only absorbs moisture but also eliminates odors—find out more. ↩

-

Calcium chloride is powerful for high-humidity situations—learn safe and effective usage. ↩

-

Proper placement prevents moisture wicking and extends box life—learn the best practices. ↩

-

Coated boards provide a surface barrier against water—learn when to choose this option. ↩

-

These household solutions can safely remove mold—get step-by-step cleaning guidance. ↩

-

Knowing when to discard damaged boxes protects your products and prevents future issues. ↩

-

Sunlight is a natural disinfectant—see how UV exposure can aid in mold remediation. ↩